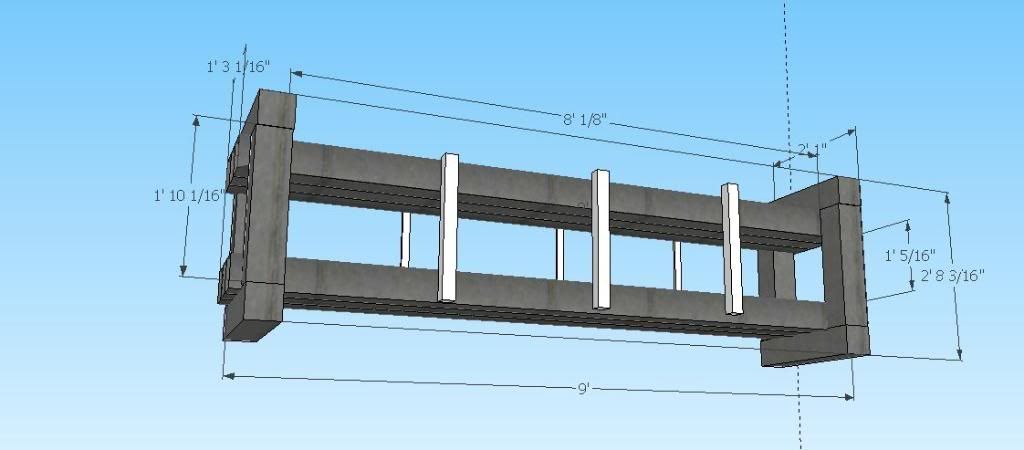

That inertia calc is for I beams. For a square hollow section, you basically calculate the inertia of the outer square and subtract the inertia of the inner square.

So outside is 5x5 = 5*5^3/12 = 52.08in^4

Inside = 5 - 2(3/8) square = (4.25)(4.25)^3/12 = 27.19in^4

Ixx = 52.08 - 27.19 = 24.89in^4

Since you have 3 beams above and below, triple that so Ixx = 24.89*3 =74.67in^4

At 50PSI you have 50 x 15" = 750lb/in

E = 29000000 PSI

L = 96"

y = 0.5h = 2.5"

Copied straight from

http://www.engineeringtoolbox.com/beam- ... _1312.html

---------------------------------------------------------------------------

Unit Load - q : 750 (lb/in)

Total Load : 72000 (lb)

Length of Beam - L : 96 (in)

Moment of Inertia - I : 74.7 (in4)

Modulus of Elasticity - E : 29000000 (psi)

Perp. distance from neutral axis - y : 2.5 (in)

Support Force - R1 : 36000 (lb)

Support Force - R2 : 36000 (lb)

Maximum Stress - ? :

28927 (psi)

Maximum Deflection - ? :

0.38 (in)

--------------------------------------------------------------------------

Alternatively, you can find an inertia table here

http://sketchup.engineeringtoolbox.com/ ... -c_79.html

They take 0.35" as the thickness, where I took 3/8" = 0.375"

Again, these are an estimated calc and likely to be high, as the pressure isn't fully distributed along the beams, only where the hoses press.

[/img]

[/img]