My first splitboard

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

My first splitboard

First board too actually. Made to be a tough and not particularly light splitboard for the rocky mountains.

Split Snowboard

167cm long

1.5cm of taper

7.7mm in the center tapering to 2mm at tip and tail

Ptex outer sidewalls and topsheet

22oz triax glass top and bottom

kevlar veil and a couple of carbon tows for show

voile splitboard hardware pattern

I have to post twice before I can post pictures I guess.

Split Snowboard

167cm long

1.5cm of taper

7.7mm in the center tapering to 2mm at tip and tail

Ptex outer sidewalls and topsheet

22oz triax glass top and bottom

kevlar veil and a couple of carbon tows for show

voile splitboard hardware pattern

I have to post twice before I can post pictures I guess.

Re: My first splitboard

dosJparker wrote: I have to post twice before I can post pictures I guess.

Re: My first splitboard

Here's the images. http://picasaweb.google.com/Parkerjohn/BoardBuilding

Core. Maple and Doug fir. The wide center strip will be the inner sidewalls for the splitboard. The core is 1/4" wider then the board so there will be 1/4 inch that needs to be cut out of the board after lamination.

Edges bent by hand. durasurf 2001 cut out with a router and template.

Router Bridge. It worked ok but next time I will use a planer jig instead.

Core with sidewall. There are a lot of insert holes that need to be cut in a splitboard.

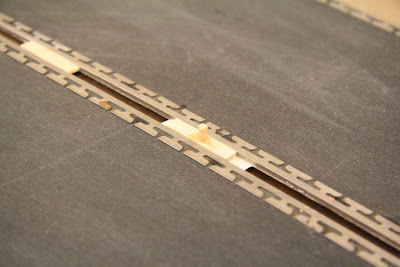

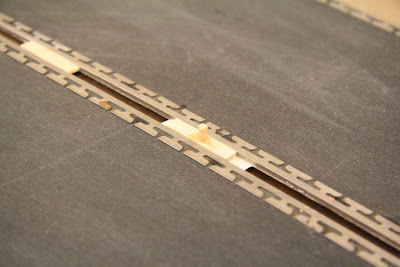

Dowels were used to align the core with the base. The two base pieces were spaced at 1/4" with pieces of basswood from the hobby shop. The dowel system worked very well. I had to cut holes through the fiberglass and VDS before laminating too.

VDS and some kevlar veil I got from Fiberglast. Hopefully it will deflect some core shots in it's life.

Me fixing a leak in the bag. No pictures from the layup unfortunately.

My high tech heating system. Kmart heating blanket with a space blanket on top. Got it pretty warm inside, no idea how warm.

finished board. Cotton cloth graphics and a couple of carbon tows for show.

More pictures of the finished board in picasa. I'm mounting hardware now, hopefully take it out for a test ride tomorrow morning or this evening.

Core. Maple and Doug fir. The wide center strip will be the inner sidewalls for the splitboard. The core is 1/4" wider then the board so there will be 1/4 inch that needs to be cut out of the board after lamination.

Edges bent by hand. durasurf 2001 cut out with a router and template.

Router Bridge. It worked ok but next time I will use a planer jig instead.

Core with sidewall. There are a lot of insert holes that need to be cut in a splitboard.

Dowels were used to align the core with the base. The two base pieces were spaced at 1/4" with pieces of basswood from the hobby shop. The dowel system worked very well. I had to cut holes through the fiberglass and VDS before laminating too.

VDS and some kevlar veil I got from Fiberglast. Hopefully it will deflect some core shots in it's life.

Me fixing a leak in the bag. No pictures from the layup unfortunately.

My high tech heating system. Kmart heating blanket with a space blanket on top. Got it pretty warm inside, no idea how warm.

finished board. Cotton cloth graphics and a couple of carbon tows for show.

More pictures of the finished board in picasa. I'm mounting hardware now, hopefully take it out for a test ride tomorrow morning or this evening.

Last edited by Jparker on Thu Apr 10, 2008 2:37 pm, edited 1 time in total.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

nice work.

Curious, did you get voile's permission?

According to a recent conversation I had with a lawyer, building a board (even for personal use) with the voile hole pattern is a violation of their patent under u.s. law.

Has voile in the past not bothered with individual board builders.

Also the interface kit does not come with the yin/yang hooks or the tip and tail hooks, so you have to buy those from voile. Again, what is their response / attitude about this?

Very cool project, just really curious about voiles opinion.

Curious, did you get voile's permission?

According to a recent conversation I had with a lawyer, building a board (even for personal use) with the voile hole pattern is a violation of their patent under u.s. law.

Has voile in the past not bothered with individual board builders.

Also the interface kit does not come with the yin/yang hooks or the tip and tail hooks, so you have to buy those from voile. Again, what is their response / attitude about this?

Very cool project, just really curious about voiles opinion.

Nice, clean process. Was looking at making a splitboard myself one day, but chickened out.

That's the most crazy thing i ever heard. You guys really got laws like that? Or are your lawyers just plain stupid.doughboyshredder wrote: According to a recent conversation I had with a lawyer, building a board (even for personal use) with the voile hole pattern is a violation of their patent under u.s. law.

Finished product. Wide angle lens makes it look like it has more taper then it really does.

Bling Spark R&D anodized split hooks. Will at Spark was nice enough to let me hog up a bunch of space in his shop and help out with this project.

mpm32 is right, you can do whatever for personal use. I ordered all the parts separately from Voile and saved money from the kit anyway.

Ambitious yeah, my next board will be a little simpler. I'm hoping to build a press this summer too. . . .

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

from the United States Patent Office website.The right conferred by the patent grant is, in the language of the statute and of the grant itself, “the right to exclude others from making, using, offering for sale, or selling” the invention in the United States or “importing” the invention into the United States.

I can only assume that Voile has decided to not pursue individual builders.

Really nice work. I hope to make a good split for myself at some point.

first ride

took it for a short ride yesterday before it got dark. It's pretty stiff, but not overly so. Seemed to ride pretty well. I built my mold with extra camber since everyone was telling me it would relax but it didn't so I have around 13mm of it. Maybe the PTEX topsheet or the heating blanket had something to do with that?

Oh, it was cheap. It's a $20 on closeout kmart heated matress cover, size full. I then picked up a "space blanket" from the local climbing store for $5. They come in little orange boxes and are emergency blankets for unplanned bivies, injuries etc.ben_mtl wrote:by the way could you give us some more details about your heated blanket ?