Thanks, chrismp!

I had been taking heaps of photos and notes over the last few months. Found I kept coming back here for information and though I should get around to making a post to get "caught-up." Hopefully I can post a bit more regularly now

Big shoutout to everyone here that has shared their stories and information so us new guys can get a good start.

chrismp wrote: ↑Thu Mar 17, 2022 4:15 am

Regarding your first two pairs, by the look of the photos those were definitely overcooked. You really need to be able to measure your temperature on the laminate as the laminate itself also provides some thermal insulation.

I think I agree with you on this & I'll explain below....but first, I gotta ask why do you think they were overcooked? What was obvious to you?

Only during my second press did I remember to get the thermocouple placed near the laminate

before pressing. (The first press I forgot to place thermocouple before pressing...) Turns out the controllers I have don't control very well at all. They drift to about +30C over setpoint over the 4 hour press cycle as well as have wild temp swings during the warmup period of about 30-40 mins. This is due to the temperature sensor being embedded into the mats at the end where the connections are. This means the sensor is

nowhere near the laminate and mostly inaccurate. I was able to

kind of compensate for the big temperature swings by pre-heating the press to 30C prior to placing the laminate in. However I was not on top of the setpoints to accomodate drift.

The resin I was using is

Kirkside K3600 with a 4-hour cure time @ 80Ckir (from the best I can tell from the data sheet...)

Currently I'm in the process of putting together a proper PID controller and once I have all the components and build an enclosure I will get that operational. It will be much more reliable and nicer to work with.

Modified Nippers

chrismp wrote: ↑Thu Mar 17, 2022 4:15 am

For the edge benders, maybe you could post a photo of your modified tile nippers, so we could check if we see anything wrong with them. Edge bending is always a chore - even after many pairs built.

- IMG_2802.JPG (90.2 KiB) Viewed 12753 times

- IMG_2805.JPG (64.1 KiB) Viewed 12753 times

- IMG_2806.JPG (68.93 KiB) Viewed 12753 times

These are the two pairs of nippers I have. The one on the right (narrow toothed). I took all the factory edge off of to get as flat a surface as I could to allow the contact point of the jaws to get as much of a "bite" as possible. They seem to work OK, but I definitely don't have the touch yet. I'm prepping my next pair and am going for a wrap up both side and around the tip (3/4 wrap??). I was able to get one edge bent pretty good, but stuffed the second. I forced it on whilst gluing and that ended up tweaking the base to where it no longer aligns with the core. I tweaked the narrow nippers a bit more after that and have got a bit better control on some test pieces, and will have another go soon.

Edge Bender (Roller Style)

- IMG_2801.JPG (108.54 KiB) Viewed 12753 times

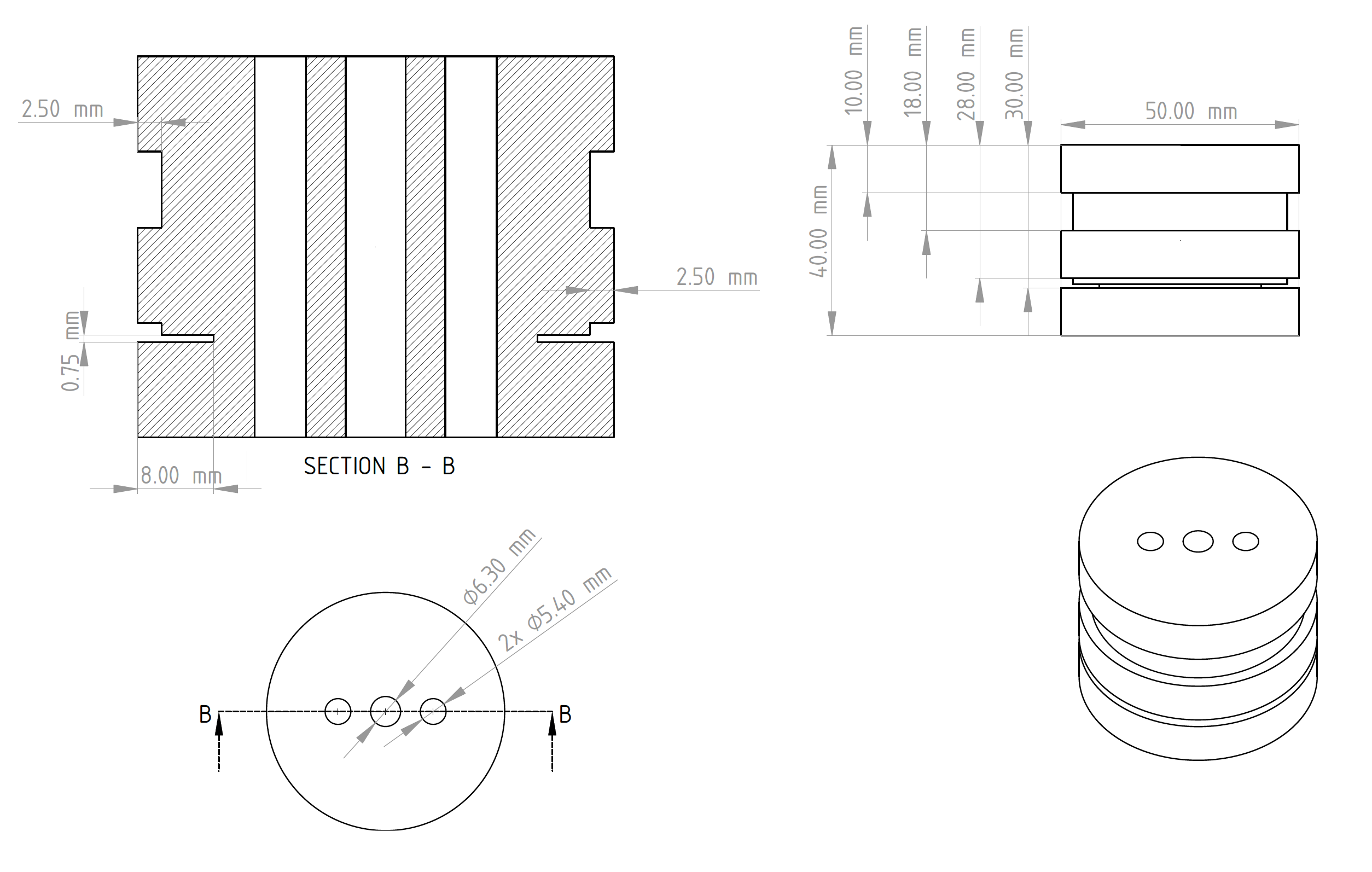

- Screen Shot 2022-03-20 at 22.19.34.png (278.95 KiB) Viewed 12752 times

I'm going to give a go at building one of the roller style benders as well. I've engaged a local fabrication shop with some drawings and will mount those to a tilting drill-press vice. Tool store had a sale this week and was able to pick the vice up for a good deal. I've added another wider notch on my roller design to run the edge through when it first comes off the spool to take the initial bend out. I achieved this with 3-jars screwed to a board previously

Edge Bender Inspiration from: