Divide Rides

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

As I've started to make boards that bend more, I have been backing up thin carbon laminates with innegra as the outer layer in the high load areas instead of S2 glass for the weight savings. It is pretty hyped so far as adding toughness to carbon composites. Won't know anything until this year is well under way here in Utah.

http://www.scenterprisesfiberglass.com/innegras.html

http://www.scenterprisesfiberglass.com/innegras.html

I hear that! I've got some too. 45/45 Biax and some plain weaved stuff!24Dave wrote:As I've started to make boards that bend more, I have been backing up thin carbon laminates with innegra as the outer layer in the high load areas instead of S2 glass for the weight savings. It is pretty hyped so far as adding toughness to carbon composites. Won't know anything until this year is well under way here in Utah.

http://www.scenterprisesfiberglass.com/innegras.html

Have not pressed any carbon board yet this season. Hope too in the next while. I've seen that card folding video before, looks like the carbon/core will still break under massive Impact but the innegra will get ya back down the hill, adds some dampening too!

I'm guessing it beats fiberglass for beefing up a carbon laminate because it wets out better or doesn't absorb water, it dissipates impact better adding toughness to protect a carbon layer, because its lighter than fb, it has a higher ultimate breaking point.

The thing that makes me skeptical is whether the resin I'm using will stretch enough (11% or whatever the innegra fiber is supposed to elongate) to really allow the fiber to do its thing. Meaning, if the too-stiff resin on the base splits or cracks, it's just the core left and the strength of the fiber wasn't really utilized -- presuming the deck laminates have buckled already.

I don't want any of my boards to break, but it is hard to experiment with these things otherwise. I guess I'll just keep reducing fiber and core strength until I find that point, then start adding again. LOL

The thing that makes me skeptical is whether the resin I'm using will stretch enough (11% or whatever the innegra fiber is supposed to elongate) to really allow the fiber to do its thing. Meaning, if the too-stiff resin on the base splits or cracks, it's just the core left and the strength of the fiber wasn't really utilized -- presuming the deck laminates have buckled already.

I don't want any of my boards to break, but it is hard to experiment with these things otherwise. I guess I'll just keep reducing fiber and core strength until I find that point, then start adding again. LOL

I'm guessing it beats fiberglass for beefing up a carbon laminate because it wets out better or doesn't absorb water, it dissipates impact better adding toughness to protect a carbon layer, because its lighter than fb, it has a higher ultimate breaking point.

The thing that makes me skeptical is whether the resin I'm using will stretch enough (11% or whatever the innegra fiber is supposed to elongate) to really allow the fiber to do its thing. Meaning, if the too-stiff resin on the base splits or cracks, it's just the core left and the strength of the fiber wasn't really utilized -- presuming the deck laminates have buckled already.

I don't want any of my boards to break, but it is hard to experiment with these things otherwise. I have a 5lb, 13 oz paulownia/maple rail 167 by 26.5 out there this year, but only under a 165lb rider. I guess I'll just keep reducing fiber and core strength until I find that point, then start adding again. LOL

The thing that makes me skeptical is whether the resin I'm using will stretch enough (11% or whatever the innegra fiber is supposed to elongate) to really allow the fiber to do its thing. Meaning, if the too-stiff resin on the base splits or cracks, it's just the core left and the strength of the fiber wasn't really utilized -- presuming the deck laminates have buckled already.

I don't want any of my boards to break, but it is hard to experiment with these things otherwise. I have a 5lb, 13 oz paulownia/maple rail 167 by 26.5 out there this year, but only under a 165lb rider. I guess I'll just keep reducing fiber and core strength until I find that point, then start adding again. LOL

If you manage to elongate the fibres by 11% the ski is trash anyway ;) Normal epoxies usually have around 3% elongation before they break, some up to 6%. This should be more than enough for our purpose.

Any of the "science mathematicians" here willing to do a quick calculation how much a ski would need to be bent in order to reach 10 elongation? Probably the ski is bent more than 180°?

Hope my writing is understandable, having kissing desease and the constant fever kills my intelligence.

Any of the "science mathematicians" here willing to do a quick calculation how much a ski would need to be bent in order to reach 10 elongation? Probably the ski is bent more than 180°?

Hope my writing is understandable, having kissing desease and the constant fever kills my intelligence.

- FigmentOriginal

- Posts: 142

- Joined: Mon Oct 24, 2011 1:13 pm

- Location: New England USA

- Contact:

I had a breakage issue with a custom titanal skwal with a carbon topsheet. Board manufacturer said it was a point load issue(explained a little on the Catek site). I use rigid solid aluminum bases on my bindings, no flex. If I were running a binding that had more flex built into it then the break might not have happened.

His solution was to run a polycarbonate plate underneath to disperse the point load. Now on an updated version of the same board and running the plates under my bindings and haven't had issues yet.

Here is one option, smaller footprint meant for alpine bindings.

http://shop.virus-snowsports.com/de/sho ... latten.htm

I use a cut-down version of these.

http://www.catek.com/snowboard-binding-spacers.htm

His solution was to run a polycarbonate plate underneath to disperse the point load. Now on an updated version of the same board and running the plates under my bindings and haven't had issues yet.

Here is one option, smaller footprint meant for alpine bindings.

http://shop.virus-snowsports.com/de/sho ... latten.htm

I use a cut-down version of these.

http://www.catek.com/snowboard-binding-spacers.htm

hmmm, did some more reading. I'm thinking the innegra will help protect the base layer composite from impacts, but probably not much help in board breakage which appears to usually be compression failure on the top side.

Could be best to just stack diamond shaped patches of unidirectional fiberglass ( or maybe Boron, edit: too expensive, $310 per board) on the deck in front and behind bindings and maybe the inside nose curve. I learned that woven fibers can have less than half the compression strength as unidirectional fibers due the angles of the weave in the fabric encouraging buckling.

Thanks for the pic Figment, and innegra actually elongates 9.5% not 11%, still, a lot.

http://www.specmaterials.com/pdfs/Enhan ... erties.pdf

http://www.specmaterials.com/pdfs/boron ... alysis.pdf

http://www-mech.eng.cam.ac.uk/profiles/ ... ers/80.pdf

Could be best to just stack diamond shaped patches of unidirectional fiberglass ( or maybe Boron, edit: too expensive, $310 per board) on the deck in front and behind bindings and maybe the inside nose curve. I learned that woven fibers can have less than half the compression strength as unidirectional fibers due the angles of the weave in the fabric encouraging buckling.

Thanks for the pic Figment, and innegra actually elongates 9.5% not 11%, still, a lot.

http://www.specmaterials.com/pdfs/Enhan ... erties.pdf

http://www.specmaterials.com/pdfs/boron ... alysis.pdf

http://www-mech.eng.cam.ac.uk/profiles/ ... ers/80.pdf

Been a long time. I've kept up somewhat on some threads, and seen some of the new guys working through the glory ons pain.

Here a few shots of the last couple presses

[/img]

[/img]

[/img]

Some new cores next to a existing 55 twin for size reference.

They will be 164 powder machines.the cores are milled out of one piece yellow cedar. These splits have a bit of flash, but they are wide boards. 27cm waist width.

[/img]

Here's the next stash of sitka spruce. Literally got second pick to Martin guitars on this log. Tight, Center heart, and clear all the way through

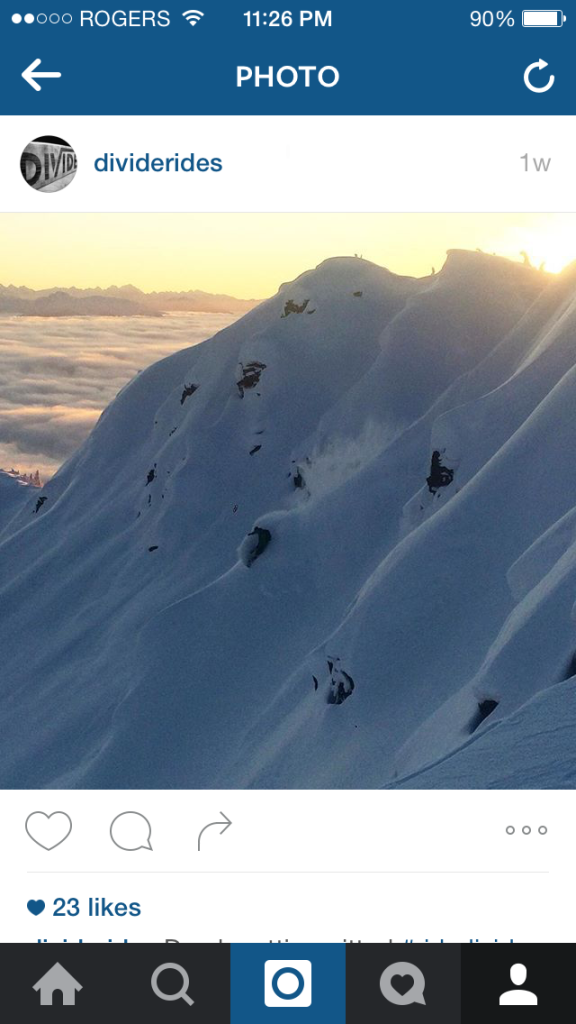

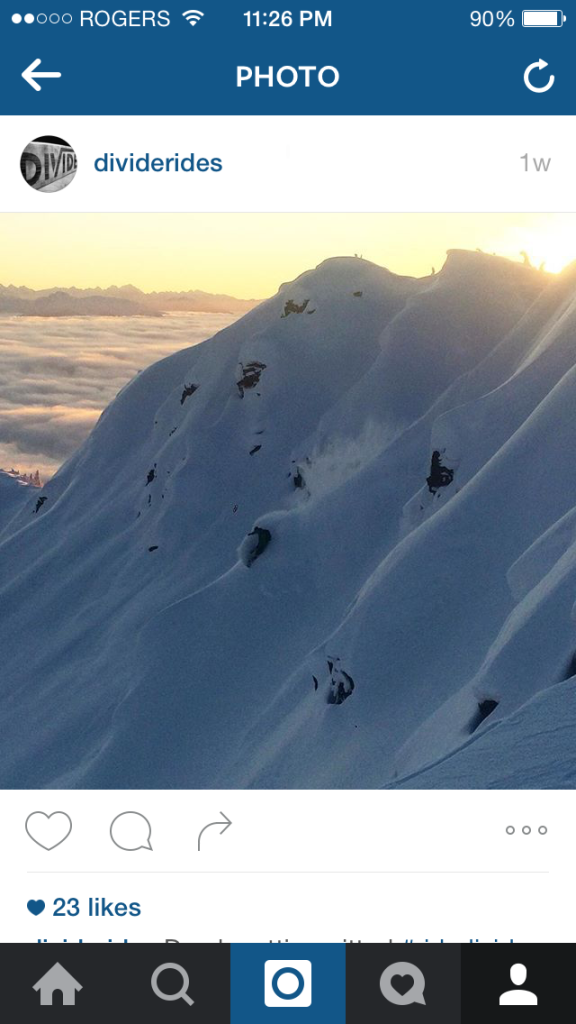

And some pow porn shots of yours truly

[/img]

[/img]

Here a few shots of the last couple presses

[/img]

[/img]

[/img]

Some new cores next to a existing 55 twin for size reference.

They will be 164 powder machines.the cores are milled out of one piece yellow cedar. These splits have a bit of flash, but they are wide boards. 27cm waist width.

[/img]

Here's the next stash of sitka spruce. Literally got second pick to Martin guitars on this log. Tight, Center heart, and clear all the way through

And some pow porn shots of yours truly

[/img]

[/img]

beautiful boards, I love the strong grain in your veneer you used, the one in pics 4&5 make the board look all dished out like a burton kids board, I dig it!

Do you cut those trees into slabs and let them dry for a summer before final milling? Reaally fresh and nice looking lumber there.

I went up to 27.5cm waist this year with size 11 feet, loving it!

Do you cut those trees into slabs and let them dry for a summer before final milling? Reaally fresh and nice looking lumber there.

I went up to 27.5cm waist this year with size 11 feet, loving it!

Haha, I cleaned out my workshop a bit in the weekend and also created a huge supply of kindling for the fire!Dtrain wrote:Dave, We usually just mill it all into 1x6, this tree had been sitting and drying for some time as is!

It still surprises me how much turns to dust and kindling in this hobby

Are your side walls rounded?

Is there a reason for doing that?

I am nobody. Nobody's perfect, so I must be perfect.

-

climberman

- Posts: 42

- Joined: Mon Aug 05, 2013 12:46 am