DIY Silicone Heat Blanket

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

The case is an old unused PC power supply. Inside is a SSR with mounted cooling from an old CPU.

Mind you do, this PID does not support SSR by default (some soldering needed). It supports 110-240 relay only up to ~2A. Hence the SSR with a fuse. SSR was ~$3 from HK with delivery.

Works well. The temp reading is fast and PID turns off/on the blanket to keep the required temp at +- a few degrees Celsius.

PID in action:

Mind you do, this PID does not support SSR by default (some soldering needed). It supports 110-240 relay only up to ~2A. Hence the SSR with a fuse. SSR was ~$3 from HK with delivery.

Works well. The temp reading is fast and PID turns off/on the blanket to keep the required temp at +- a few degrees Celsius.

PID in action:

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

camhard wrote:8 parallel circuits, with 4 lengths of wire each circuit.

i was going to pick it up from jacobs online (cat. number NW28500). 500ft for $17, seems pretty good.

thanks for checking over the numbers.

From experience 8 parallel circuits seems problematic, that is a lot of connections that could fail. What you could do is use wire that is 2ohms per and have 4 circuits.

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

I build with 10 parallel circuits and do not see it as a problemstroublemaker wrote:

From experience 8 parallel circuits seems problematic, that is a lot of connections that could fail. What you could do is use wire that is 2ohms per and have 4 circuits.

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

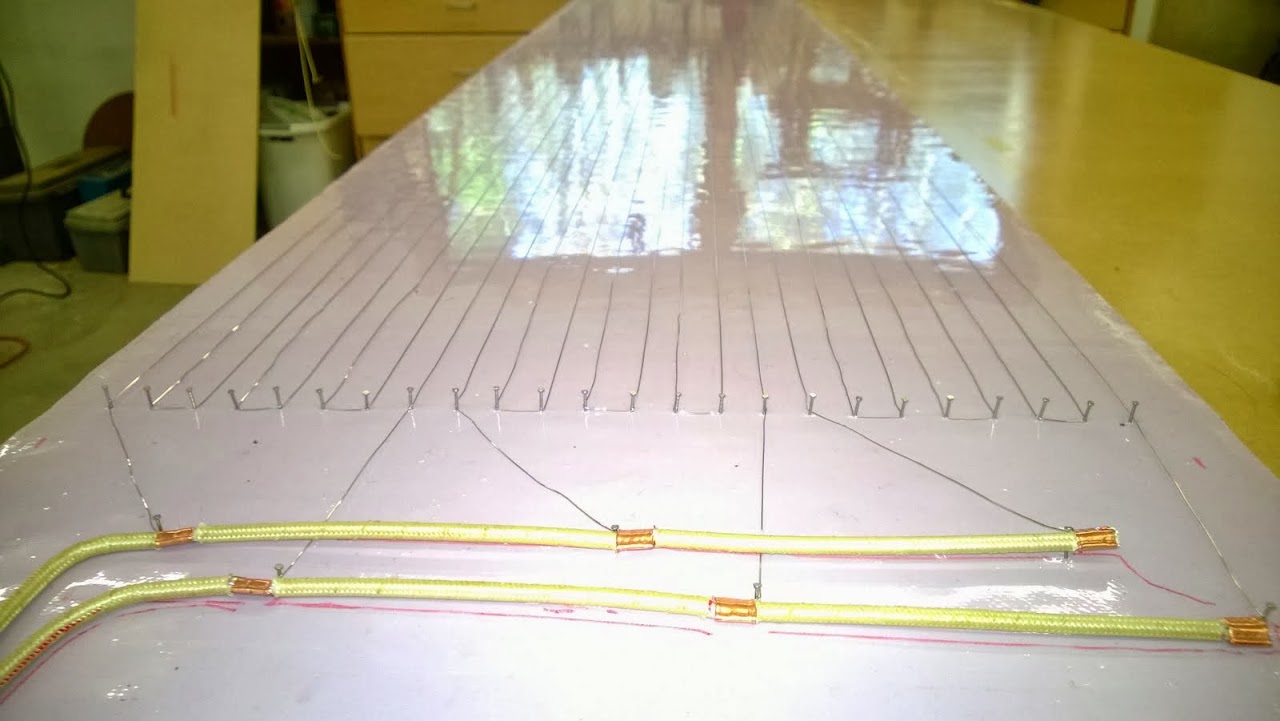

Well I am finally overcoming my ski building nemesis, the heat blanket.

I got some good silicone mats finally using the smooth-on product with 24 hour cure time.

I have now cut the mats down (20mm bigger than finished size), made the buss bars and run the wires. The way I made the buss bar system I have only 1 -ve wire that needs insulation from the +ve buss bar.

One thing I did find was that evenly spacing the nails results in uneven wire spacings due to the thickness of the nails. For perfect wire spacing you need to account for the nail thickness which isnt hard to do.

I am now going to put the top mat on and press it at low pressure so I get a nice clean finish without bumps

I got some good silicone mats finally using the smooth-on product with 24 hour cure time.

I have now cut the mats down (20mm bigger than finished size), made the buss bars and run the wires. The way I made the buss bar system I have only 1 -ve wire that needs insulation from the +ve buss bar.

One thing I did find was that evenly spacing the nails results in uneven wire spacings due to the thickness of the nails. For perfect wire spacing you need to account for the nail thickness which isnt hard to do.

I am now going to put the top mat on and press it at low pressure so I get a nice clean finish without bumps

-

troublemaker

- Posts: 217

- Joined: Sun Jan 22, 2012 10:03 pm

- Location: The Dalles Oregon

Looks really good. Nice buss bar. Wait till you see mine....I just finished my first blanket and it we well. One potential issue I have is that I can feel the wires. Is that going to be a problem?. I figured adding another layer of glass and silicone could help.

I'll post pics. How do I make the pics larger?

I'll post pics. How do I make the pics larger?

Thanks boss!troublemaker wrote:That looks AWESOME!! Great job!

I owe it all to you to be honest. Without your help I never would have got them done.

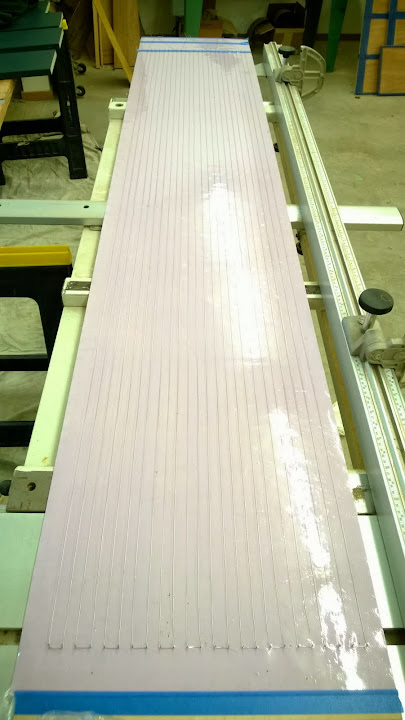

The second one is in the press now, the first one tested perfectly and gets hot fast. I seem to be having success with the sestos pid. It gets to about 4 degrees from target temp and then starts shutting off.

A few more pics

I can slightly feel the wires in my mat. Mine is very thin too, 1.6mm total.bhenry wrote:Looks really good. Nice buss bar. Wait till you see mine....I just finished my first blanket and it we well. One potential issue I have is that I can feel the wires. Is that going to be a problem?. I figured adding another layer of glass and silicone could help.

I'll post pics. How do I make the pics larger?

I made sure I twisted the ends so that they were neat and would not try to poke through the silicone. I also used offcuts of silicone mat to double up over these areas for a bit of extra safety.

As for the pics create a photobucket account and post the link

Another blanket. Three circuits, 240v and about 1500 watts. Heating area is about 85" long and 16" wide. It ended up about 1.5mm thick and i can feel the wires through the cloth. The lead wires are 8g silver heat resistant wire I had. Over kill, but the price was right. Price- $100.00

#2 today, and then the temp controller.

#2 today, and then the temp controller.

Last edited by bhenry on Sat Nov 09, 2013 9:48 am, edited 2 times in total.