Weather was OK today so got some time to cut out a few pairs, well almost, ran out of daylight so still one PORTLY left to cut out.

All still need sidewalls beveled and sanded. Bases still new to be ground.

Starting with the daughters new skis,

142cm 130-97-120 12m radius.

Rockered tip and tail slight camber under foot.

Once again I had a bit of core bridging. Kids skis are so short with such an abrupt taper they don't flex into the mold like longer skis do. Thought I'd learned that last pair.

You can just see the "treefrog" stenciled on the core, thought the white cotton would go clearer.

Shown here in comparison with her old 130's. Probably hang on to these as the new ones are probably too fat for the hard groomer days, we'll see.

Next Whizzer for piste, Dark green on left

All mountain carving ski and my first using bamboo.

183cm 140-92-125 17m radius, Fairly stiff flex

Cores are just shy of 3mm at tip and tail so an obvious line where they join.

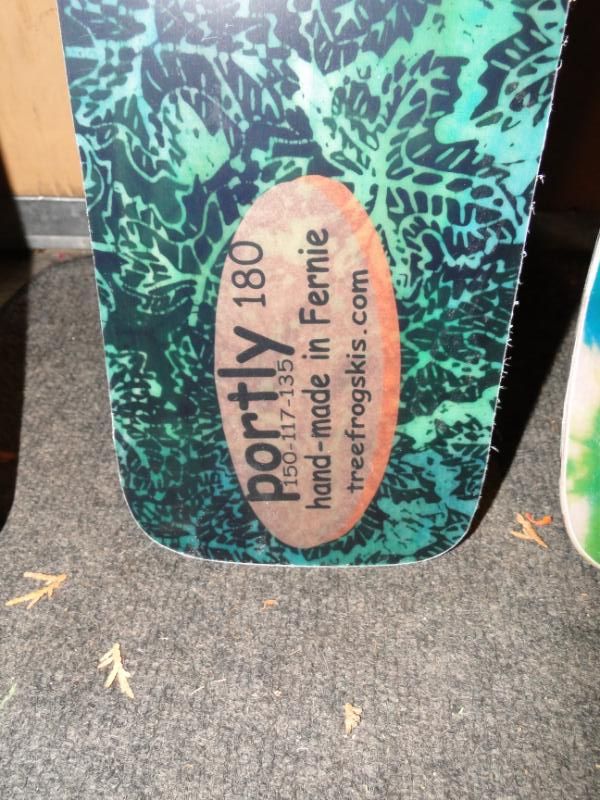

Next Portly a big 180, 23m radius.

Shot of the bases "treefrog" turned out looking pretty good. Waiting to see what it looks like after a base grind.

Flouro green base is fairly translucent and shows everything thru it.

looks blotchy but a base grind might clear that up I'll keep you posted.

Now the issues...

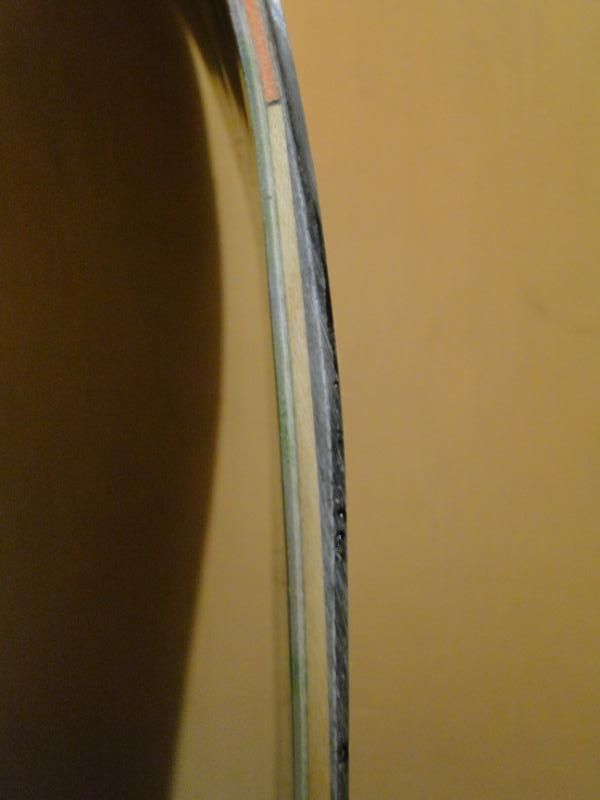

Portly's cores were a bit wider than I would normally make so over hung the base and edge a fair amount.

Once the vacuum pulled it into the mold the cores cracked near the side wall joint and tipped up.

I was able to open it up and put a bit of tip spacer under the over hanging bit but by that time the epoxy was starting to gel and I couldn't get it to sit back down flat.

This left a weird little line you can see in the second photo near the right edge.

Will not effect the ski but still a cosmetic issue that would relegate this ski to second status.

I switched to a lighter poly to put on top the layup to keep the epoxy off my vacuum membrane,. This has solved the issue of creases making marks on my top sheet shown earlier.

Now on to the next.

Layed up the reverse reverse ski yesterday.

Cut it pretty close running out of hardener and having to stretch it a bit.

Everything wetted out OK and this is what it looked like in the press.

Rocker looked pretty good in the mold but slumped quite a bit when it came out. should still have a bit more than the last pair.

Hope to get the last portly and the MOFO's cutout soon.

Then it's off to JV's shop to base grind. (grindrite is still there as it won't ever get down in the dungeon) Bolt on some binders and pray for snow!

Still have 1 set of cores left, the repaired one is waiting to build another Portly. See if I get time this year.

Back to work end of next week.

Ski building has been my physio therapy

Later

sam