Building on Bill's first post... we got back from our BC test fest in March 2010 absolutely stoked on the Floaters. The skis ripped in deep snow (absolutely, most definitely the biggest permagrin in my life, to date), and we had quite a few guys saying they would be interested in buying a pair if they were available. At that point we decided to try a run of 30 pairs of Floaters for the Fall of 2010.

So here’s a quick story of our first production run, including some stumbling blocks that first year. We’ve decided to give out some detailed information here, reason being is that it's hard to start building your own boards on a bigger scale and we want to encourage everyone to try, even if that means potential competition down the road from a new microbrew manufacturer like us. If you want to give it a go, more power to you. Competition in the market is a good thing.

We didn’t start out with a few hundred grand in the bank to finance a factory and all of the tooling you need to do everything on your own. We started out with a modest budget, a press we’d had built out in California, and some hand tools from Home Depot, packed into Bill’s garage in Grand Rapids. (Thankfully Bill has a very patient wife that allowed us to use the garage for pressing skis, trimming, brewing beer, etc. Vehicles can sleep outside. Thanks Kath!)

The press:

Ski Press

Ski Press by

Epic Planks, on Flickr

We'd pretty much finalized our materials order in early spring, and were pumped to get rolling. As we were tweaking our graphics for our first real production run, we found out via the TGR boards that a custom ski manufacturer in Europe already had a shape called the Floater. That was an “oh shit” moment for us, because we'd already leaned hard on James (our original graphics maestro, and now business partner) for his time to finish the design, and time was tight. We finally ended up settling on a new name: Crop Duster, which has generated its fair share of laughs along with some unintended consequences – Like how people feel way too comfortable ripping farts in and around our demo tent while calling out Crop Duster. It’s not always the easiest name to explain either, like when Akihiko Mizutani of Japan requested that we teach him the origin of the name “Crop Duster.”

Cores ended up being one of the toughest things to get ahold of that first year. We knew we needed to use quality, consistent cores, but didn't have full confidence to produce the same core every time because of our limited machinery. We decided to outsource our cores to a guy we found on ski builders from the East Coast. We paid him, and he promised delivery by May. After months of excuses, we finally received our cores in September, when we had hoped to have production wrapped up. Some cores were great, some weren’t, but the moral of the story was that they lacked consistency. We used the ones that were useable and found an alternate source for the rest. This was one of the first lessons: it sucks to depend on others to get what you need, before you have the capability to build or do everything yourself. The core situation completely screwed up our production schedule, and with promised deliveries there were some sleepless nights.

The cores once they came in:

Poplar Core

Poplar Core by

Epic Planks, on Flickr

While we were waiting on the cores we were starting in on some of the other tasks. Our bases were cut with the “run a router around a machined wood blank” method, which obviously isn’t optimal but it is acceptable if you pay attention and clean up rough spots. Our straight steel edges (from CDW) were bent by hand – tons of fun without a quality edge bender. It took a loooong time to bend the edges for all of the skis.

Attaching edges

Attaching edges to base

Attaching edges to base by

Epic Planks, on Flickr

Other material sources we used that year : Fiberglass from Vectorply, sublimated nylon (again, we wanted to get away from PBT) topsheets and UMHW bases from Miller Studio in Washington, sidewall & tip/tail spacer material from Crown Plastics in Ohio, and Resin/Epoxy from QCM Industrials (now Forrest Paint).

Once we finally got the cores in, we were ready to rock and roll. Pressing went pretty well, and we finished up production just in time to unveil the Crop Duster at a Dendrite Studios/Poor Boyz double film premiere we threw in Grand Rapids.

Crop Duster, get 'em while they're hot

Just pressed

Just pressed by

Epic Planks, on Flickr

We ended up selling all but a couple pairs of skis out of our initial run of 30 pairs (we also lost a couple of sales because of the delay in getting our cores, thanks again dude!). Those extra pairs were used for the athletes that we hooked up to sponsor and help get the word out about Epic Planks. We have worked hard to target guys that are great skiers, but more importantly, great people. This has been amazing for us for getting feedback on our designs and being able to make quick modifications to meet their needs. We have been fortunate enough to sponsor backcountry ski guides, big mountain skiers, and park rats.

In February 2011, we attended our first retailer show/demo, the MRA Test Fest at Boyne Mountain Michigan. This was our first real ski show with buyers from shops throughout the Midwest. We had a blast meeting new people and getting into some shops. There were quite a few people stoked on seeing a small Michigan based brand, while some of the sales reps for the bigger brand definitely were giving us the cold shoulder. We walked away from the show pretty pumped, with an order from Skis.com/Summit Sports and Bill & Paul’s Sporthaus.

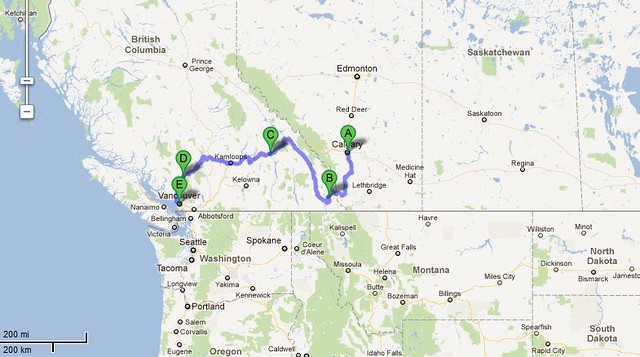

We wrapped up the 2010/2011 season with a ski trip back to British Columbia with 3 of our sponsored riders and our friends from Dendrite Studios to TLH Heliskiing in Gold Bridge, BC, which was un-freaking-believable. We and the other guys wrote up a couple articles about the trip:

ESPN Freeskiing (clicky),

Dendrite Studios (clicky),

b4apres (clicky), and

Untracked Guides (clicky). The trip was a blast, except for the blown out ACL and torn meniscus that Bill took back to Michigan as a souvenir.

Here is the edit Dendrite put together from our trip.

And a few final photos:

Crop Dusters

Crop Dusters by

Epic Planks, on Flickr

This photo kinda gives you some perspective on how gigantor a place like TLH is – that is a BIG heli, a Bell 212, sitting on a glacial moraine.

Heli on a moraine

Heli on a moraine by

Epic Planks, on Flickr

Then, looking across the glacier and where the heli is sitting in the above photo, this is one of the faces the guys shredded that day (I was sitting across the valley with Athan filming the shots, some of which come up in the video we posted above.)

One of the faces skied by Epic Planks athletes Alex Blais and Jon Whelan at TLH Heli Skiing.

One of the faces skied by Epic Planks athletes Alex Blais and Jon Whelan at TLH Heli Skiing. by

Epic Planks, on Flickr

Speaks for itself

Alex Blais at TLH

Alex Blais at TLH by

Epic Planks, on Flickr

Cheers,

Brian