Hose/tube questions

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

Hose/tube questions

We are getting ready to build a press much like a ski press, but there are some huge differences related to the objective, which I hope to get some help with... We don't build snowboards yet, but I believe that this press building method is a different, and should be another simple way of building even snowboard and ski presses.

The objective is to build a press for pressing longboards/skateboards which will be able to attain high laminating pressure, (over 100psi) which does not require the use of a male mold.

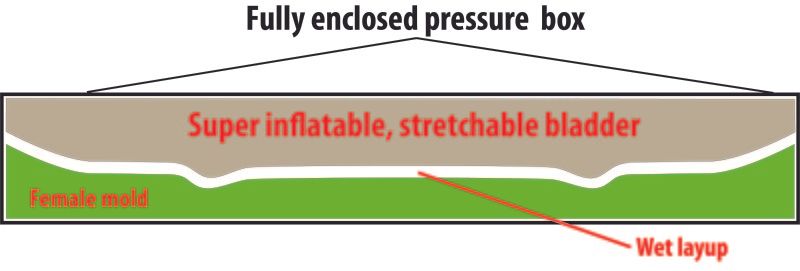

I feel like its been done before, maybe not just like this, but its been done. The press will virtually be a pressure box, which is fully enclosed, where a female form/mold will be inserted, along with the wet layup, the press closed tight, and then the bladder inflated. The one thing I need to find, which is proving tough to locate, is a rubber hose, which has VERY high stretch capabilities. Something exactly like an automotive inner tube would work great. This tube, will be inflated inside the press box, and will come into direct contact with the layup, sitting on top of the female mold. The idea would be for the bladder to fill every empty cubic inch of space the inside of the press, and to press the veneer into place, with even pressure, and without popping!

I would love some help with the process, specifically when it comes to finding rubber hose that will stretch and fill the inside of a 12"x5"x60" box, with some considerable topographical changes in the deck.

I must say, Despite the coaxing of friends and fellow builders for months now, I only just started browsing skibuilders today, and I love this website!

The objective is to build a press for pressing longboards/skateboards which will be able to attain high laminating pressure, (over 100psi) which does not require the use of a male mold.

I feel like its been done before, maybe not just like this, but its been done. The press will virtually be a pressure box, which is fully enclosed, where a female form/mold will be inserted, along with the wet layup, the press closed tight, and then the bladder inflated. The one thing I need to find, which is proving tough to locate, is a rubber hose, which has VERY high stretch capabilities. Something exactly like an automotive inner tube would work great. This tube, will be inflated inside the press box, and will come into direct contact with the layup, sitting on top of the female mold. The idea would be for the bladder to fill every empty cubic inch of space the inside of the press, and to press the veneer into place, with even pressure, and without popping!

I would love some help with the process, specifically when it comes to finding rubber hose that will stretch and fill the inside of a 12"x5"x60" box, with some considerable topographical changes in the deck.

I must say, Despite the coaxing of friends and fellow builders for months now, I only just started browsing skibuilders today, and I love this website!

Last edited by Drang on Mon Feb 20, 2012 4:49 am, edited 1 time in total.

You cant try these guys but I emailed them 2 weeks ago with no reply.

http://atlinc.com/inflatables.html

http://atlinc.com/inflatables.html

-

twizzstyle

- Posts: 2207

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

we have probably 20 different mold sets we use for different decks, and I can say, that for a longboard, with LOTs of 3d aspects to some of the molds, not needing to make the male will be awesome. So the benefits are many. Less time spent building molds being the main benefit.

We currently use an I beam-pneumatically controlled hydro press, with 36 tons of pressure, as well as a vinyl vacuum bag, and a polyurethane vac bag for complex bends.

Ill post some pictures of what we currently, do, as well as diagrams of this press, as soon as my account has been up for a full day, and has 2 legitimate posts.

We currently use an I beam-pneumatically controlled hydro press, with 36 tons of pressure, as well as a vinyl vacuum bag, and a polyurethane vac bag for complex bends.

Ill post some pictures of what we currently, do, as well as diagrams of this press, as soon as my account has been up for a full day, and has 2 legitimate posts.

-

twizzstyle

- Posts: 2207

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

skidesmond

- Posts: 2338

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

HHmm a good brain teaser.... I can see why you'd like to go this route. So you need a supper flexible/strecthy hose that can take high pressure. Have you thought about using some kind of small/mini bags filled w/ sand, saw dust, plastic pellets.... that you could lay/fit over the lay up and positioned over lower areas of the of the female mold. When the hose inflates it will place pressure on the mini bags and press the mini bags into the female/bottom mold. Just thinking out loud......

Let us know what you figure out.

Let us know what you figure out.

from Rich at ATL : "All of our snowboard involvement has been with press bladders" so that's a good route..

and maybe make some wood shims to put in between the bladder and the top of the enclosure to conform it into the molds of different shapes?

Try these guys also http://www.cement-engineering.com/compositeproducts.htm Latex might conform better

and maybe make some wood shims to put in between the bladder and the top of the enclosure to conform it into the molds of different shapes?

Try these guys also http://www.cement-engineering.com/compositeproducts.htm Latex might conform better

Skammy, I think you may have found the one. There is a HUGE slew of websites out there, with hundreds of pages of specs of countless rubber hoses, but nothing has fit the bill yet. I don't like the idea of having someone make me a custom bladder, because of price. So many materials which might just do what I want to do, but I feel like I am just going to jump on the one I find first, and see how it goes. The inside of the press, being fully enclosed, will not allow for the bladder to push through in any areas. Our veneer is 12" wide, and the press will also be exactly 12" wide. so the bladder won't crease anywhere either. The height of the area between the top of the layup, and the press can be adjusted to whatever we feel is enough space to be able to work with all of our different molds, but that won't over stretch our bladder and cause it to either not laminate properly over the entire width of the blank, or worse yet, to pop. I really like the idea of latex too, simply because it stretches SO much. The main question is (without knowing how to technically word it), how small of a hole, can the material squeeze into, causing the bladder to pop? I am going to call this composite place tomorrow.

I am very thankful to the input here. My steel is arriving this thursday, and I very much hope to have a bladder here, (or tube) to work with from the start, so the whole thing can go together smoothly.

There is another line of questioning that I am working with at this moment, which may be of interest to some in the ski building community. In an ideal world, we will be pressing a million decks per day, complete with composite layers and graphics top and bottom, with very little "shop footprint". If we can incorporate our graphics into the layup, along with the composites, and everything else, this will be most excellent for efficiency. IF we locate a bladder material which will be able to come into direct contact with epoxy, without sticking to it, and at the same time, without leaving any marks in the finish of the board, from seams, or ridges on the bladder itself. I don't know if latex will stick to epoxy or not, but it will certainly provide a smooth surface for epoxy work.

Sorry for making you read this much babble... Soon enough we shall have some pictures for progress, and maybe this method of approach can drizzle into the ski building arena eventually. In the mean time, here are a few pictures of a few of our shapes.

Here is some non bagged carbon, on a 1 inch drop deck, with 5/8" concave

Here we have a 3/8" v-pocket drop deck, with 5/8" concave

Here is a Ferrari I saw at the mall last month

Here is a crazy one I like to show off we call it "Deadend"

This one has .625" of rocker, kick tails, and 7/16" concave

I am very thankful to the input here. My steel is arriving this thursday, and I very much hope to have a bladder here, (or tube) to work with from the start, so the whole thing can go together smoothly.

There is another line of questioning that I am working with at this moment, which may be of interest to some in the ski building community. In an ideal world, we will be pressing a million decks per day, complete with composite layers and graphics top and bottom, with very little "shop footprint". If we can incorporate our graphics into the layup, along with the composites, and everything else, this will be most excellent for efficiency. IF we locate a bladder material which will be able to come into direct contact with epoxy, without sticking to it, and at the same time, without leaving any marks in the finish of the board, from seams, or ridges on the bladder itself. I don't know if latex will stick to epoxy or not, but it will certainly provide a smooth surface for epoxy work.

Sorry for making you read this much babble... Soon enough we shall have some pictures for progress, and maybe this method of approach can drizzle into the ski building arena eventually. In the mean time, here are a few pictures of a few of our shapes.

Here is some non bagged carbon, on a 1 inch drop deck, with 5/8" concave

Here we have a 3/8" v-pocket drop deck, with 5/8" concave

Here is a Ferrari I saw at the mall last month

Here is a crazy one I like to show off we call it "Deadend"

This one has .625" of rocker, kick tails, and 7/16" concave

why not use automotive tube? i did a quick search on ebay and several tubes that fit your size needs popped up for about 50 USD.

eg: http://www.ebay.com/itm/11-2-28-11-2x28 ... 4ab0a3c401

thats cheap enough to give it a try i guess...

now, one thing that i'm really interested in is: how do you plan to build that press box?

eg: http://www.ebay.com/itm/11-2-28-11-2x28 ... 4ab0a3c401

thats cheap enough to give it a try i guess...

now, one thing that i'm really interested in is: how do you plan to build that press box?

the box will be constructed with angle iron, and flat steel. It will be lined internally with wood, and will have a hinged side to allow easy access to whats inside. The bladder will be pinched at both ends, and will have an air nozzle attached somewhere convenient. I have drawings on paper, but I think Ill just wait to show you guys what actually comes out. I will most definately post pics of the build as it moves along.

As far as using automotive inner tube, this is something that I was thinking would be a last resort. I would prefer to utilize something flat, and straight. If the bladder needs to inflate to say 12x4x60, then we should be able to get away with using a 12 inch tube, but I kinda prefer to use something I won't have to worry about popping. I hoep to get in touch with a few of these places today, in hopes to get some solid leads.

As far as using automotive inner tube, this is something that I was thinking would be a last resort. I would prefer to utilize something flat, and straight. If the bladder needs to inflate to say 12x4x60, then we should be able to get away with using a 12 inch tube, but I kinda prefer to use something I won't have to worry about popping. I hoep to get in touch with a few of these places today, in hopes to get some solid leads.

well, a bird told me today, that silicone can stretch enough to fill the inside of my press, if its only 2 inches in diameter. I found it here, but I have to buy 5 meters to play that game... Here is a link.

http://www.lindemannsilikon.de/en/index ... ager01.php

I also talked to Acme, as well as the people who make the bladders for Burton and they can build me whatever I want, but we didn't get into price... rubber hose, 12 inches would be great. I found 36 inch wide, and 48 inch wide hosing, but I can't find 12 inch hose, or even 5 inches. I think 4-5 inches would do the trick....

the search goes on. I have 2 computers with over 20 tabs each opened, and am bound and determined to locate exactly what I need. I am beginning to look towards the hollow carbon paddle industry for examples too. Jeez, I think too far outside the box apparently. Someone out there has either done this, and likes keeping secrets, or it just hasn't been done. Oh well. I wish I could have kept this a secret too, I think it will blow the longboard building process wide open.

http://www.lindemannsilikon.de/en/index ... ager01.php

I also talked to Acme, as well as the people who make the bladders for Burton and they can build me whatever I want, but we didn't get into price... rubber hose, 12 inches would be great. I found 36 inch wide, and 48 inch wide hosing, but I can't find 12 inch hose, or even 5 inches. I think 4-5 inches would do the trick....

the search goes on. I have 2 computers with over 20 tabs each opened, and am bound and determined to locate exactly what I need. I am beginning to look towards the hollow carbon paddle industry for examples too. Jeez, I think too far outside the box apparently. Someone out there has either done this, and likes keeping secrets, or it just hasn't been done. Oh well. I wish I could have kept this a secret too, I think it will blow the longboard building process wide open.