Printing on veneers

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

To solve the issues with both paper feed and UV resistance get yourself a printer that has a backside paper feed, lets you choose thicker papers, supports long roll paper by default and has pigmented inks!

One great example is the Epson Stylus Photo 2100 (2200 for the US guys). It's usually sold very cheap on ebay (Got mine for 50 bucks!!)

The original ink cartridges are pretty expensive so I bought some high quality pigment ink made by Inktec plus some refillable cartridges. Cheap and easy as pie! You could even add a continuous ink system to save even more time refilling.

I've tried printing on both wood veneer and cotton cloth (latter one attached to a thick roll of paper using spray adhesive) and both worked fine with great results.

The pigmented inks are more opaque than the standard dye inks used in most printers which is also an advantage when printing veneers.

Only downer with this printer is that you have to print a page every other day so the printhead doesn't clog. But that's a small price to pay.

That being said be aware that the printhead could already be clogged and needs some serious cleaning which might destroy the printhead. So you better try the printer first before buying one used.

One great example is the Epson Stylus Photo 2100 (2200 for the US guys). It's usually sold very cheap on ebay (Got mine for 50 bucks!!)

The original ink cartridges are pretty expensive so I bought some high quality pigment ink made by Inktec plus some refillable cartridges. Cheap and easy as pie! You could even add a continuous ink system to save even more time refilling.

I've tried printing on both wood veneer and cotton cloth (latter one attached to a thick roll of paper using spray adhesive) and both worked fine with great results.

The pigmented inks are more opaque than the standard dye inks used in most printers which is also an advantage when printing veneers.

Only downer with this printer is that you have to print a page every other day so the printhead doesn't clog. But that's a small price to pay.

That being said be aware that the printhead could already be clogged and needs some serious cleaning which might destroy the printhead. So you better try the printer first before buying one used.

Thanks Falls, that's great to know. I'm still kicking ideas around. I have an idea of where I want to take the graphics, but I've been a bit pre-occupied. Bamboo is a good option, but expensive in the UK. I can get hold of poplar relatively cheaply ...

Inktec looks good - thks for the heads up! There's definitely an issue with the opacity of the standard. Yeah, your right about checking the condition of second-hand printers - tricky.

Cheers all!

Inktec looks good - thks for the heads up! There's definitely an issue with the opacity of the standard. Yeah, your right about checking the condition of second-hand printers - tricky.

Cheers all!

well, Inktec alone isn't the solution. they also make dye inks.Richuk wrote: Inktec looks good - thks for the heads up! There's definitely an issue with the opacity of the standard. Yeah, your right about checking the condition of second-hand printers - tricky.

here's a picture that makes the difference very clear:

every pair of glasses is filled with the same color. the one in the front being the pigmented ink and the one in the back dye ink.

you really need a printer that supports the use of pigment inks to get the benefits. every other printer will clog within a few pages due to their smaller nozzle sizes.

another benefit of pigmented inks is their increased UV lightfastness.

although i might sound like a printer salesperson i am the opposite actually...having tried six different printers for making ski/snowboard graphics I finally have settled on a model that fulfills my needs completely without compromise.

nope, the method i use has nothing to do with dye sublimation although you could modify my printer to use dye sub inks.Richuk wrote:Sounds like you have your solution sorted - so looking forward to seeing more of your results. I did you research your solution on a dye sublimation forum?

i might try this some time if the new heat blankets are up for the temperatures needed for dye subbing.

what i do is regular inkjet direct printing on paper/cloth/veneer.

it's just that pigment based inks easily outperform the regular dye inks for our applications.

but there are only very few printers that use pigment inks and have the capability to print long and thick sheets.

there are a few others out there mostly made by Epson and HP, but most models i found have some sort of limitation.

if you have any further questions on specific models i might be able to help you find a solution that works for you.

Thks Chris, that's a kind offer. I opted for the Epson Stylus photo 1400, then I found the hack for the DX3800 - lol. To be honest I was surprised it allowed the veneer through the machine. I understand pigment inks are ok for the 1400 and they appear to be a great option for veneers, as they sit on the surface.

Many thanks for the push in the right direction!

Many thanks for the push in the right direction!

-

skidesmond

- Posts: 2338

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

-

Eirik Hanes

- Posts: 53

- Joined: Tue Nov 09, 2010 11:47 am

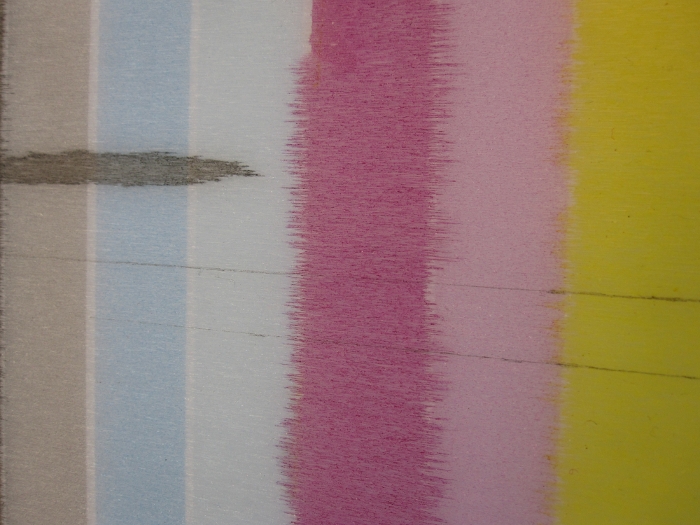

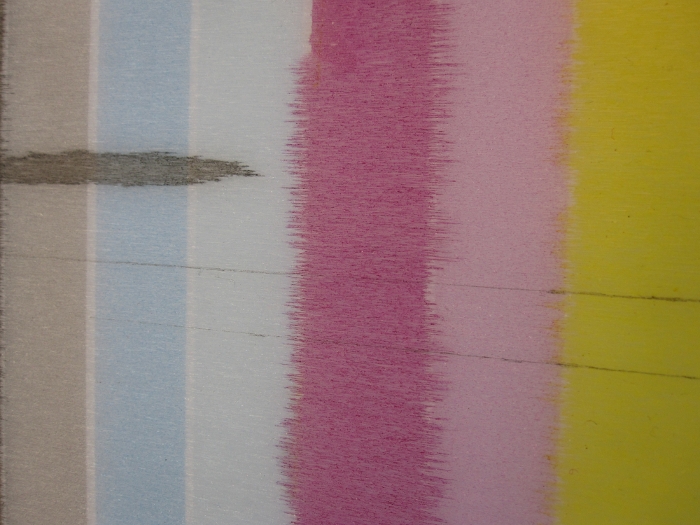

i finally got the chance to print directly on some uhmpe.

i didn't have any topsheet lying around so i used clear base material.

printer used was an epson stylus photo 2100 and the ink is on the treated side of the base. printing on the glossy side works too, but i didn't take any photos of that.

the main problem is the ink bleeding as you can see in the photos. on the glossy side bleeding wasn't much of a problem, but the ink can be smeared off easily.

i didn't have any topsheet lying around so i used clear base material.

printer used was an epson stylus photo 2100 and the ink is on the treated side of the base. printing on the glossy side works too, but i didn't take any photos of that.

the main problem is the ink bleeding as you can see in the photos. on the glossy side bleeding wasn't much of a problem, but the ink can be smeared off easily.

-

hallvardaase

- Posts: 18

- Joined: Wed Nov 17, 2010 11:27 pm

- Location: Norway

I will try this pretty soon. Im probably getting a Espon Stylus Photo R800 and a CISS with pigment ink. I think it is the cheapest printer with that satifies your suggested demands.chrismp wrote:To solve the issues with both paper feed and UV resistance get yourself a printer that has a backside paper feed, lets you choose thicker papers, supports long roll paper by default and has pigmented inks!

I've tried printing on both wood veneer and cotton cloth (latter one attached to a thick roll of paper using spray adhesive) and both worked fine with great results.

The pigmented inks are more opaque than the standard dye inks used in most printers which is also an advantage when printing veneers.

Only downer with this printer is that you have to print a page every other day so the printhead doesn't clog. But that's a small price to pay.

That being said be aware that the printhead could already be clogged and needs some serious cleaning which might destroy the printhead. So you better try the printer first before buying one used.

Do you have any pictures of wath you skis look like with this kind of printing? Do you get satisfying uv-restiance even over several years?

Pics of new ski and the same ski after a season (or four) would be great if anyone have them:-)

Ugh, post resurrection!

Well, I'm still using an Epson 2100 to print my topsheets, but in the meantime I've resorted to printing the graphics on matte paper. After printing I seal the underside with a couple of coats of water based white acrylic paint which prevents the epoxy from seeping through the paper during pressing (this would dull the graphics). Then I apply multiple coats of 2k polyurethane varnish on top to protect the graphic. After pressing I apply a couple more coats of the PU varnish that also cover the edge of the graphic.

The printer inks are supposed to last for about 100 years (i guess this is with inside use...but I made some test with placing samples outside for a couple of months now and they still look the same as the sample piece hidden away in a drawer.

Well, I'm still using an Epson 2100 to print my topsheets, but in the meantime I've resorted to printing the graphics on matte paper. After printing I seal the underside with a couple of coats of water based white acrylic paint which prevents the epoxy from seeping through the paper during pressing (this would dull the graphics). Then I apply multiple coats of 2k polyurethane varnish on top to protect the graphic. After pressing I apply a couple more coats of the PU varnish that also cover the edge of the graphic.

The printer inks are supposed to last for about 100 years (i guess this is with inside use...but I made some test with placing samples outside for a couple of months now and they still look the same as the sample piece hidden away in a drawer.