Vacuum Mold Pics please

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

PowderKing

- Posts: 20

- Joined: Mon Feb 08, 2010 6:21 am

- Location: Davos CH and Laren NL

- Contact:

Vacuum Mold Pics please

I'm looking for some vacuum mold pictures. I want to see how it's set up. Thanks.

Building skis when there ain't no pow!

-

PowderKing

- Posts: 20

- Joined: Mon Feb 08, 2010 6:21 am

- Location: Davos CH and Laren NL

- Contact:

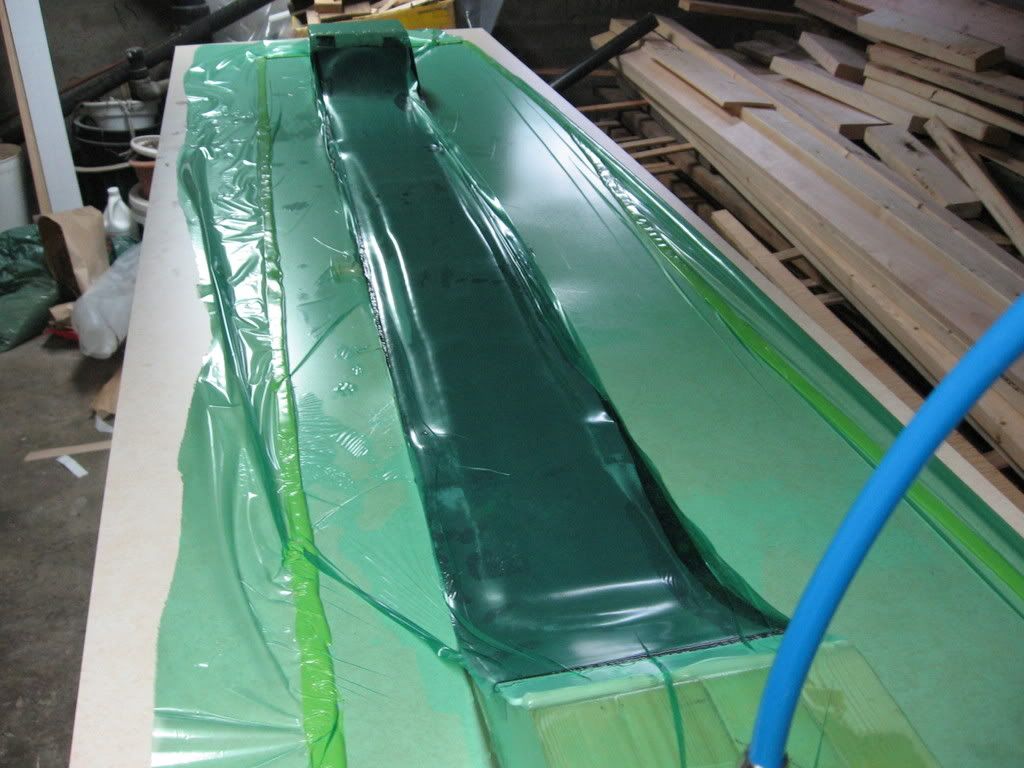

Hi . The mold is made of 8@90x45 building pine laminated into a block and then CNC to shape. Then I vac bag a 3 mm MDF sheet to give it a hard surface. Sprayed with white furniture lacquer to make it all look clean and to stop any spilt epoxy sticking to it.

This is the mold being 're-cambered' (I changed my camber profile) on the CNC you can see the 3mm MDF comming off at the top and the pine core being re cut.

Here's a sketch.

90x45mm is metric 4x2. 3mm is 1/8inch. I use the pine rather than MDF as it's much lighter (for loading into vac bag etc.) and cheaper.

C.

This is the mold being 're-cambered' (I changed my camber profile) on the CNC you can see the 3mm MDF comming off at the top and the pine core being re cut.

Here's a sketch.

90x45mm is metric 4x2. 3mm is 1/8inch. I use the pine rather than MDF as it's much lighter (for loading into vac bag etc.) and cheaper.

C.

- Head Monkey

- Posts: 310

- Joined: Sun Jul 17, 2005 4:53 pm

- Location: Carnation, WA

- Contact:

Links to a bunch of my old vacuum bagging pics here:

http://www.skibuilders.com/phpBB2/viewt ... 4050#14050

http://www.skibuilders.com/phpBB2/viewt ... 4050#14050

Everything I know about snowboard building, almost: MonkeyWiki, a guide to snowboard construction

Free open source ski and snowboard CADCAM: MonkeyCAM, snoCAD-X

Free open source ski and snowboard CADCAM: MonkeyCAM, snoCAD-X