The first one...........

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

The first one...........

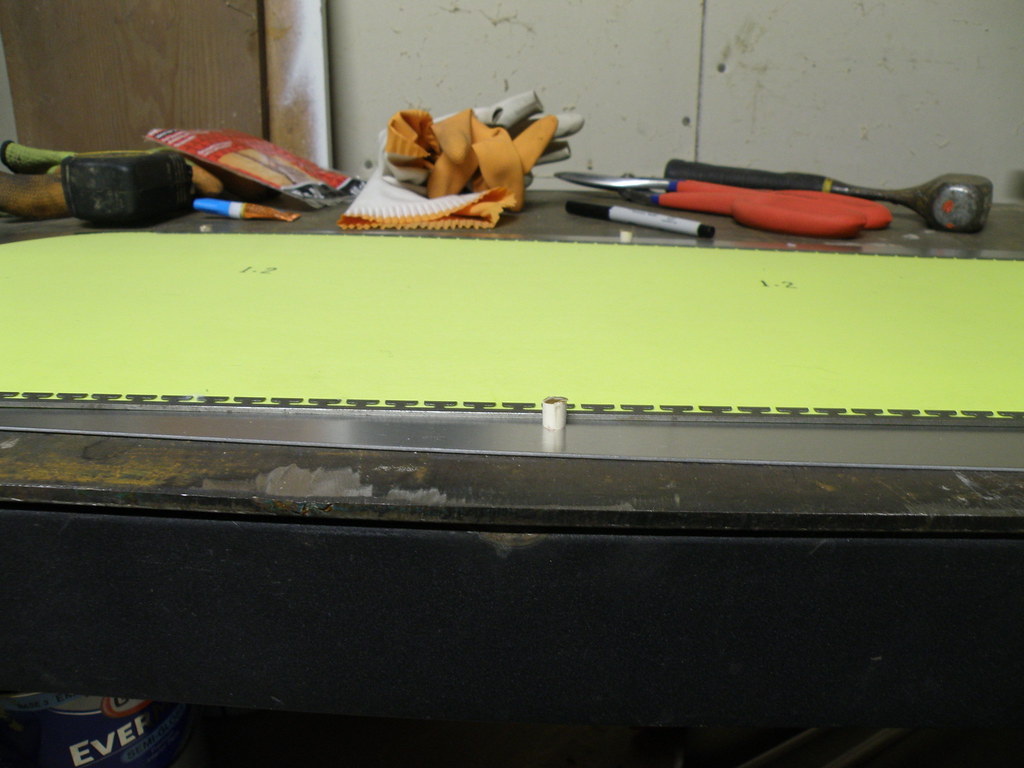

Is in the press right now.

I used too much epoxy (didn't think I used enough) and it just poured out all over the place.

Specs and construction:

177 cm length. 26.0 at the waist. 140cm contact. 10m sidecut.

Layup:

Base

vds over edges

20 oz triax

3oz carbon fiber x directly under bindings

3oz carbon fiber insert reinforcement

4 6 inch vds strips centered on radius

poplar / ash core

5oz kevlar x extending from center to end of contact length

4 6 inch vds strips centered on radius

p tex sidewalls and tip protectors (interlocked)

pics shortly.

so stoked.

I used too much epoxy (didn't think I used enough) and it just poured out all over the place.

Specs and construction:

177 cm length. 26.0 at the waist. 140cm contact. 10m sidecut.

Layup:

Base

vds over edges

20 oz triax

3oz carbon fiber x directly under bindings

3oz carbon fiber insert reinforcement

4 6 inch vds strips centered on radius

poplar / ash core

5oz kevlar x extending from center to end of contact length

4 6 inch vds strips centered on radius

p tex sidewalls and tip protectors (interlocked)

pics shortly.

so stoked.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

The problems:

I got a little bit of super glue under the base on the tail and the ptex stuck to the cassette and ripped off of the base when I removed the board.

I didn't use any mold release and cleaning my aluminum plates is gonna be a bitch.

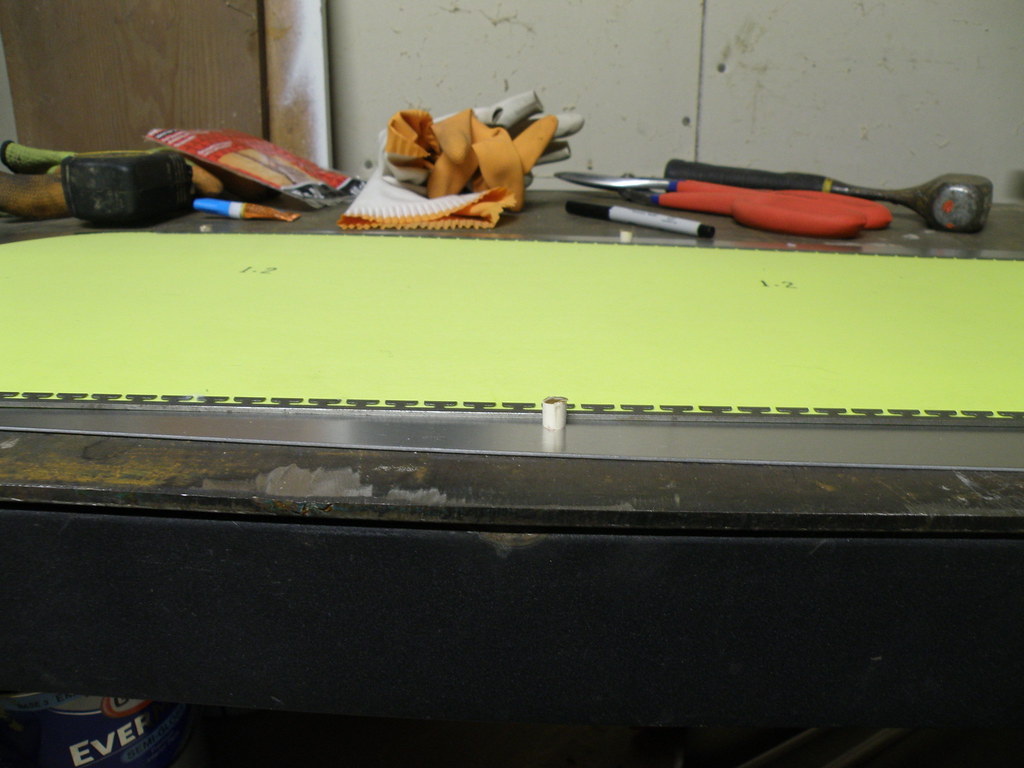

I used dowels super glued to an aluminum sheet for my cassette. It worked damn near perfect, allowing me to lay the sidewalls in during pressing and keeping the core and base perfectly centered. I didn't use enough dowels though and the sidewall blew out in two places. Epoxy filled the gap so I think it will hold up to some riding.

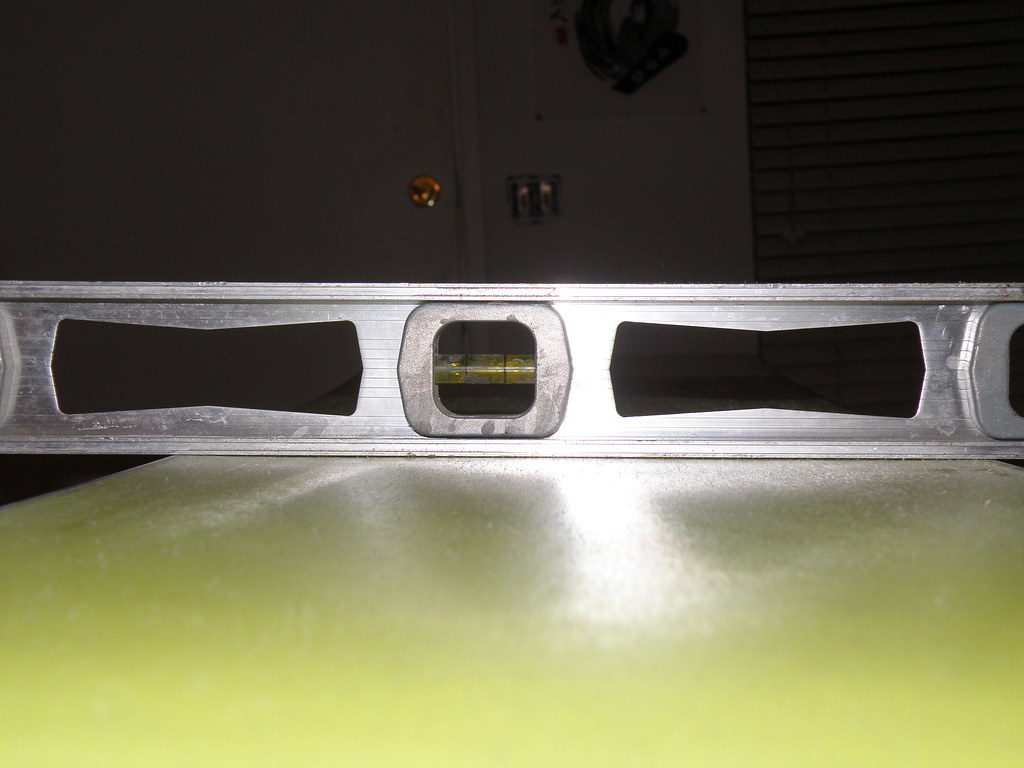

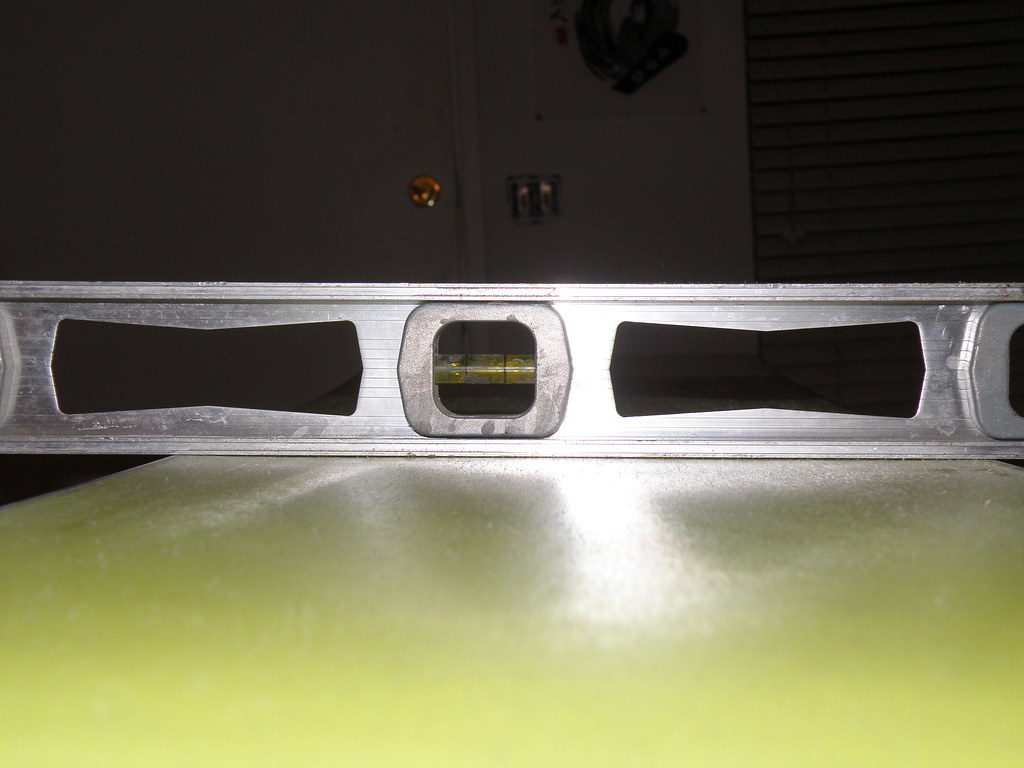

Because I free floated the sidewalls and was pressing at about 70psi at the laminate I didn't think I needed to compensate for the edge tabs. Wrong. The ripples in the base are miniscule and will base grind out, but there is a visible ridge around the entire board caused by the sidewall being too thick.

I got a little bit of super glue under the base on the tail and the ptex stuck to the cassette and ripped off of the base when I removed the board.

I didn't use any mold release and cleaning my aluminum plates is gonna be a bitch.

I used dowels super glued to an aluminum sheet for my cassette. It worked damn near perfect, allowing me to lay the sidewalls in during pressing and keeping the core and base perfectly centered. I didn't use enough dowels though and the sidewall blew out in two places. Epoxy filled the gap so I think it will hold up to some riding.

Because I free floated the sidewalls and was pressing at about 70psi at the laminate I didn't think I needed to compensate for the edge tabs. Wrong. The ripples in the base are miniscule and will base grind out, but there is a visible ridge around the entire board caused by the sidewall being too thick.

Oh....and mold release is your friend

When we were cruising and pressing 15 or so skis a day, obviously, everything was mold released.

Most of what we were cleaning was sticky tack we used to secure the base, and a little mek/acetone + paint scrapper allowed us to clean the cassettes in just a few minutes, quick mold release, and it was back to the press.

Getting epoxy of a normal cassette might be a real bitch though. Even mold releasing every time ended up building up epoxy over time (especially early on when we were using too much epoxy). I ended up really just needing to replace the cassettes....

Good luck.

How did the sidewall bonding go, besides the few blowouts?

When we were cruising and pressing 15 or so skis a day, obviously, everything was mold released.

Most of what we were cleaning was sticky tack we used to secure the base, and a little mek/acetone + paint scrapper allowed us to clean the cassettes in just a few minutes, quick mold release, and it was back to the press.

Getting epoxy of a normal cassette might be a real bitch though. Even mold releasing every time ended up building up epoxy over time (especially early on when we were using too much epoxy). I ended up really just needing to replace the cassettes....

Good luck.

How did the sidewall bonding go, besides the few blowouts?

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

What did you use for mold release? Did you source it in the Tacoma area?

I used a sheet of .040 aluminum which was about 50.00 from online metals. I then cut little pieces of dowel and superglued them on to the aluminum. The dowels came off with the flash.

looking at those pics, I am surprised the sidewalls even stayed in at all.

Another interesting thing happened in that the base expanded around the dowels, kind of making an unintended cross between magnetraction and vario grip. Made me wonder if magnetraction may have happened by accident at some point in the history of mervin.

Next board I will use more dowels, and leave the base some room to expand. Or maybe something else. I was thinking about tacking the excess base material to the aluminum plate as a guide for the edge and then gluing the dowels on to that base material. I don't know. Fun trying to figure it out though.

Snowboard Connection is rad. They hooked up the base grind and edge tune for the bro discount.

I used a sheet of .040 aluminum which was about 50.00 from online metals. I then cut little pieces of dowel and superglued them on to the aluminum. The dowels came off with the flash.

looking at those pics, I am surprised the sidewalls even stayed in at all.

Another interesting thing happened in that the base expanded around the dowels, kind of making an unintended cross between magnetraction and vario grip. Made me wonder if magnetraction may have happened by accident at some point in the history of mervin.

Next board I will use more dowels, and leave the base some room to expand. Or maybe something else. I was thinking about tacking the excess base material to the aluminum plate as a guide for the edge and then gluing the dowels on to that base material. I don't know. Fun trying to figure it out though.

Snowboard Connection is rad. They hooked up the base grind and edge tune for the bro discount.

- Head Monkey

- Posts: 310

- Joined: Sun Jul 17, 2005 4:53 pm

- Location: Carnation, WA

- Contact:

For mold release I like SC Johnson Wax, original formula. Source: Home Depot and the like. Works like a champ.

The Seattle area has fantastic sources of metal. I’m making a pickup from Alaskan Copper & Brass of new mold skins tomorrow in fact. Much cheaper. If you need random bits of metal, then Metal Shorts is your friend.

Good luck!

The Seattle area has fantastic sources of metal. I’m making a pickup from Alaskan Copper & Brass of new mold skins tomorrow in fact. Much cheaper. If you need random bits of metal, then Metal Shorts is your friend.

Good luck!

Everything I know about snowboard building, almost: MonkeyWiki, a guide to snowboard construction

Free open source ski and snowboard CADCAM: MonkeyCAM, snoCAD-X

Free open source ski and snowboard CADCAM: MonkeyCAM, snoCAD-X

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

Thanks for the tip. I knew I was spending more than necessary at online metals. I was in a hurry though, and ended up waiting three damn weeks anyway. I have an account at metal shorts, but they are so damn expensive it's nuts. I get all of my steel from tacoma steel, but had never sourced aluminum.

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact: