Snowboard profile information

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

Snowboard profile information

Time has come to start up a new project. My son wants a new snowboard. The problem is it will only be slightly wider than his stance. I'm not sure why but this is what he wants.

I'm looking for suggestions on the profile for the board. My skis are 12mm center and the typical board is about 7 or 8 mm ? I think that the board being so short and he so big that the profile in the center should be thicker but how much tincker is the question. Any ideas? He has laminated the wood and made his template and we are ready to go so any help or ideas would be great.

Thanks much,

rockaukum

he is about six feet tall and the board is just over three feet in length

I'm looking for suggestions on the profile for the board. My skis are 12mm center and the typical board is about 7 or 8 mm ? I think that the board being so short and he so big that the profile in the center should be thicker but how much tincker is the question. Any ideas? He has laminated the wood and made his template and we are ready to go so any help or ideas would be great.

Thanks much,

rockaukum

he is about six feet tall and the board is just over three feet in length

-

heelside76

- Posts: 15

- Joined: Mon Mar 05, 2007 8:06 pm

- Location: Placerville area

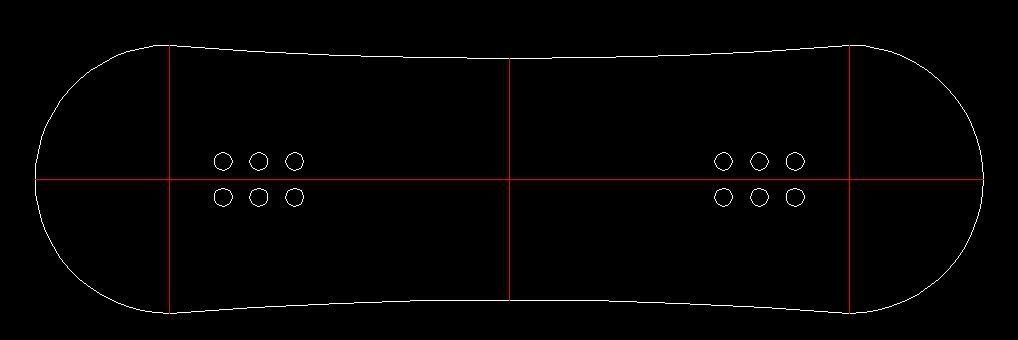

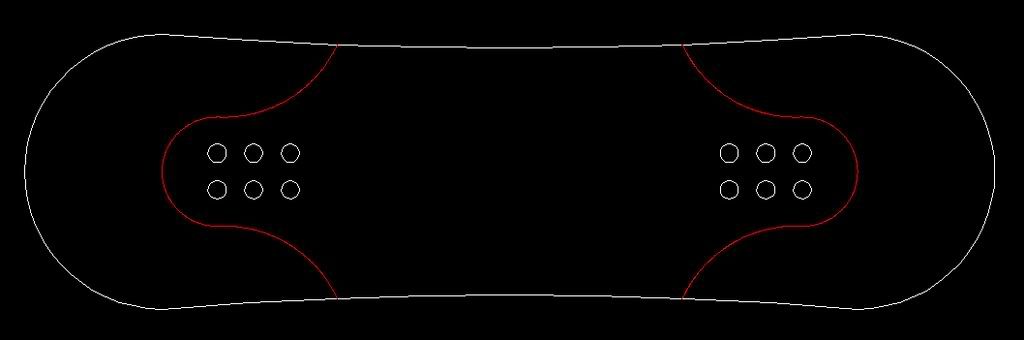

i came up with the 106 because i took the stance i was using on my other board and extended it enough to encompass the tip and tail. i chose to make a small board for just messing around on lazy days and to take with us when we go to places with snow for example camping or to my grandparents cabin. i believe my stance is around 21 inches and i will be centered on the board. thanx for any tips!

almost forgot... the tip and tail will be 30cm wide and the middle will be 27cm wide

almost forgot... the tip and tail will be 30cm wide and the middle will be 27cm wide

Last edited by heelside76 on Tue Jul 17, 2007 8:42 am, edited 1 time in total.

Next Project~162 Race Board

Hydrant,

Thanks for the help on this. I'm not too familliar with snowboards. What I thought was that the board profile should be thicker that normal because it will be alot shorter? Does that sound correct at least for the center dimension, the tips should probably be as before (=2mm).

Thanks much,

ra

Thanks for the help on this. I'm not too familliar with snowboards. What I thought was that the board profile should be thicker that normal because it will be alot shorter? Does that sound correct at least for the center dimension, the tips should probably be as before (=2mm).

Thanks much,

ra

rockaukum, heelside76, there is a nice SS here http://www.skibuilders.com/phpBB2/viewtopic.php?t=486 that Bambi made. It works pretty good for figuring out how much flex you want in a board, but you will need to enter some data from skis you have already made/skied to get a comparison so the data is useful. I have put in my skis and a few from the gallery here to get an idea of where to go next.

I entered the data from your post and found a deflection of .7 mm Here are the dimensions I entered. I had to assume tip and tail length and a couple of other bits.

Ski Dimensions

Running length: 700mm

Tip Width: 300mm

Waist Width: 270mm

Tail Width: 300mm

Tip Start 350mm

Tail Start 350mm

Core Profile

Mount Start 0mm

Mount End 0mm

Tip Thickness 2mm

Mount Thickness 8mm

Tail Thickness 2mm

My first pair has 9.75 mm of deflection just to give you an idea. My dimensions for a soft to medium stiff ski.

Ski Dimensions

Running length: 1600mm

Tip Width: 128mm

Waist Width: 87mm

Tail Width: 108mm

Tip Start 800mm

Tail Start 800mm

Core Profile

Mount Start 200mm

Mount End 250mm

Tip Thickness 2mm

Mount Thickness 10.6mm

Tail Thickness 2mm

You’re looking at a pretty stiff plank even at 8mm tapered to 2mm. This does not take into account camber but like I said you will need to enter data to make a comparison.

Most of the snow boards I've used are pretty flexy. IMO soft to medium stiffness. The SS will let you get there but its very thin. That length of a snowboard will always be very stiff and you will be mounting bindings at the thinnest part of the board too.

Not trying to discourage. Just throwing out some data that might be useful.

Hafte

I entered the data from your post and found a deflection of .7 mm Here are the dimensions I entered. I had to assume tip and tail length and a couple of other bits.

Ski Dimensions

Running length: 700mm

Tip Width: 300mm

Waist Width: 270mm

Tail Width: 300mm

Tip Start 350mm

Tail Start 350mm

Core Profile

Mount Start 0mm

Mount End 0mm

Tip Thickness 2mm

Mount Thickness 8mm

Tail Thickness 2mm

My first pair has 9.75 mm of deflection just to give you an idea. My dimensions for a soft to medium stiff ski.

Ski Dimensions

Running length: 1600mm

Tip Width: 128mm

Waist Width: 87mm

Tail Width: 108mm

Tip Start 800mm

Tail Start 800mm

Core Profile

Mount Start 200mm

Mount End 250mm

Tip Thickness 2mm

Mount Thickness 10.6mm

Tail Thickness 2mm

You’re looking at a pretty stiff plank even at 8mm tapered to 2mm. This does not take into account camber but like I said you will need to enter data to make a comparison.

Most of the snow boards I've used are pretty flexy. IMO soft to medium stiffness. The SS will let you get there but its very thin. That length of a snowboard will always be very stiff and you will be mounting bindings at the thinnest part of the board too.

Not trying to discourage. Just throwing out some data that might be useful.

Hafte

i think the core thickness at the waist should be somewhere around 6.0-6.5mm to allow most of the board flex to come from the waist to avoid it feeling like a 2X6 when riding. most boards in the 160cm plus range are

around 7mm and cores for 154/156cm are usually in the ballpark of

around 6.5 for reference. a softer midsection will allow him to lift the

nose of the board and load up the midsection for spring when initiating ollies. one problem that i see is that the core thickness under the bindings and towards the tips is going to be really thin because the core has to taper down the the 2mm tipfill thickness, within a couple inches of the outside edge of the bindings will be 2mm and the tips will begin to rise.

hope i'm making sense. making a steeper/shorter core taper may help with this problem when you profile the core. you may have to customize the inserts to get them to the right heigth.

having never built a short board this is the best advice i could give,

in reality, pretty much anything you come up with will be really fun to ride, and fun is what it is all about. love to see the finished product.

jason

around 7mm and cores for 154/156cm are usually in the ballpark of

around 6.5 for reference. a softer midsection will allow him to lift the

nose of the board and load up the midsection for spring when initiating ollies. one problem that i see is that the core thickness under the bindings and towards the tips is going to be really thin because the core has to taper down the the 2mm tipfill thickness, within a couple inches of the outside edge of the bindings will be 2mm and the tips will begin to rise.

hope i'm making sense. making a steeper/shorter core taper may help with this problem when you profile the core. you may have to customize the inserts to get them to the right heigth.

having never built a short board this is the best advice i could give,

in reality, pretty much anything you come up with will be really fun to ride, and fun is what it is all about. love to see the finished product.

jason

i agree with hafte on the idea that this size board will always feel stiff.

i think i would really shoot for a 6mm core thickness as opposed to anything thicker. even at 6mm this board would feel very stiff.

i would also keep the tip/tail length down to 8-10cm from the end of the RL to the end of the tips. this will allow for a longer RL and a thicker core underfoot.

i think the reason most of the shortboard mfg. build them 120-140cm

is to allow for a reasonable length from binding to end of running length.

having the extra length enables a thicker core under the bindings and

the use of standard inserts, also the nose and tail will have a little flex/pop for ollies, nose presses, and blunt slides.

jason

i think i would really shoot for a 6mm core thickness as opposed to anything thicker. even at 6mm this board would feel very stiff.

i would also keep the tip/tail length down to 8-10cm from the end of the RL to the end of the tips. this will allow for a longer RL and a thicker core underfoot.

i think the reason most of the shortboard mfg. build them 120-140cm

is to allow for a reasonable length from binding to end of running length.

having the extra length enables a thicker core under the bindings and

the use of standard inserts, also the nose and tail will have a little flex/pop for ollies, nose presses, and blunt slides.

jason

-

heelside76

- Posts: 15

- Joined: Mon Mar 05, 2007 8:06 pm

- Location: Placerville area

i would think about doing a two stage taper. figure the max you

could safely reduce your insert height and still have enough thread engagement with the binding screws, and profile core gradually

(almost like normal) to this dimension in the insert pack area, then

profile the remainder of the core to the end of the running length

at a steeper profile to match tip fill dimensions= two stage. i think doing this would provide a little more useable flex and help prevent tip breakage from such a blunt steep profile.

just remove the resin cap from the insert and grind down to safe min height, chase treads and glue the cap back on.

hope this helps, i'm sure there is other ways to build one of these

but this is the best i could come up with.

jason

could safely reduce your insert height and still have enough thread engagement with the binding screws, and profile core gradually

(almost like normal) to this dimension in the insert pack area, then

profile the remainder of the core to the end of the running length

at a steeper profile to match tip fill dimensions= two stage. i think doing this would provide a little more useable flex and help prevent tip breakage from such a blunt steep profile.

just remove the resin cap from the insert and grind down to safe min height, chase treads and glue the cap back on.

hope this helps, i'm sure there is other ways to build one of these

but this is the best i could come up with.

jason

I agree about the max insert size however I don't think we will be grinding any more inserts. On the first board we did just that and the heat from the grinding weakened the threads and they pulled out.

We will be looking for smaller height inserts to use and bring the board down to that height. I have been thinking about doing a double taper on the board. The normal taper as described then turning the core on a slight edge with and new jig and doing a taper from the outside of the inserts down to the side edge? I would hope this would help with making the board not too stiff throughout the length? We use a phneumatic press so I'll have to figure that out too, Maybe use some high density foam to fill the tapered edges?

RA

We will be looking for smaller height inserts to use and bring the board down to that height. I have been thinking about doing a double taper on the board. The normal taper as described then turning the core on a slight edge with and new jig and doing a taper from the outside of the inserts down to the side edge? I would hope this would help with making the board not too stiff throughout the length? We use a phneumatic press so I'll have to figure that out too, Maybe use some high density foam to fill the tapered edges?

RA

-

heelside76

- Posts: 15

- Joined: Mon Mar 05, 2007 8:06 pm

- Location: Placerville area