Page 1 of 1

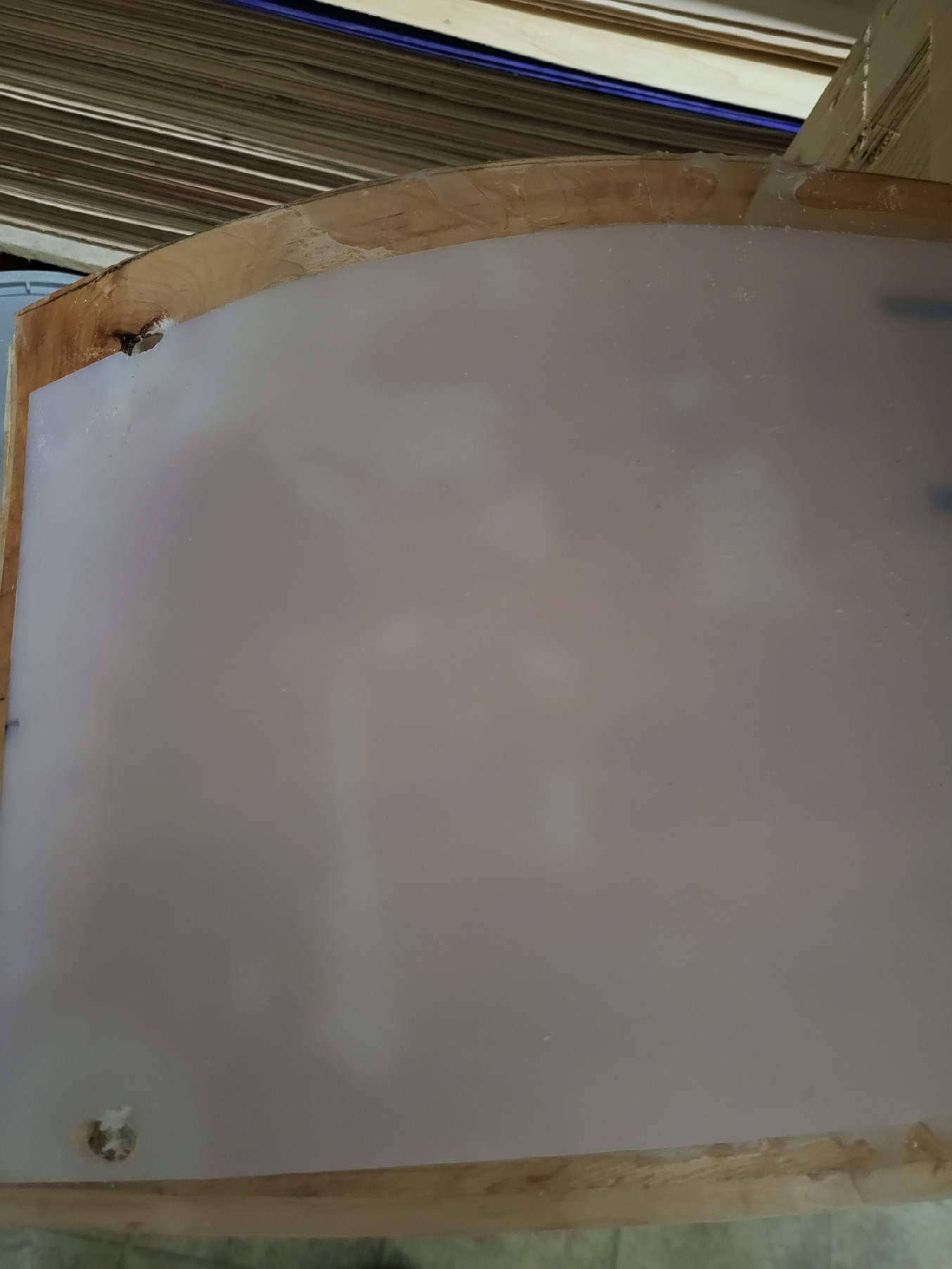

White spots showing through base material.

Posted: Fri Nov 25, 2022 3:11 pm

by SSSGAV

I'm working on a project laminating white UHMW to maple veneer and I have pressed many successful ones in past years however this year I have had several come out of the press with white spots visible through the base. I can't seem to determine what the issue is. I have tried more epoxy, less epoxy. We are roughing up the surface and flame treating the base. Could these be air pockets? Any other ideas?

- 20221125_170606-01.jpg (397.21 KiB) Viewed 1970 times

Re: White spots showing through base material.

Posted: Mon Nov 28, 2022 12:42 am

by chrismp

Looks a bit like air pockets - especially since they clearly occur around the knots you can see in the picture. What type of press are you using?

Re: White spots showing through base material.

Posted: Mon Nov 28, 2022 2:17 pm

by SSSGAV

Hydraulic cold press.

Re: White spots showing through base material.

Posted: Tue Nov 29, 2022 5:58 am

by Jonrezz

yeah I agree with chrismp - in addition to his question - are you providing a way to "bleed" excess epoxy? think of how a typical ski squeezes excess expoxy out the sides when pressed - these could also be epoxy pockets from excess having nowhere to go.

Re: White spots showing through base material.

Posted: Tue Nov 29, 2022 10:05 am

by vinman

Agree, looks like air. Increase your pressure and make sure it’s fairly even.

Re: White spots showing through base material.

Posted: Tue Nov 29, 2022 12:20 pm

by sammer

Looking at your pic, I think the answer is shown just above the p-tex.

Looks like bubbly cured epoxy.

Could be cavitation from your spreading technique?

Wet out your maple and your base. Try not to whip up any bubbles.

If you're using heat the air will expand and those bubbles have no where to go.

Just my $0.69

sam

Re: White spots showing through base material.

Posted: Wed Nov 30, 2022 3:18 am

by chrismp

SSSGAV wrote: ↑Mon Nov 28, 2022 2:17 pm

Hydraulic cold press.

Could be a couple of things then. Your pressure might not be even enough (it's hard to get mold surfaces even and matching perfectly) - to mitigate this, you could use a thin layer of soft material (silicone foam sheets work well as epoxy doesn't stick to them) in the press on top of the base material to get a more even pressure distribution.

Another reason might be your epoxy already kicking before it gets into the press. Check the working time of your epoxy and compare that to how long it takes you to get everything into the press after mixing the epoxy. However, this is not an exact science as working time is usually stated for a mix of 100 grams in a cup - so if you mix significantly more than this and leave it in the cup, it will go off quicker and on the other hand spreading the epoxy on the workpiece will prolong working time if it hasn't already started kicking (i.e. getting too warm).

Re: White spots showing through base material.

Posted: Wed Nov 30, 2022 6:08 pm

by vinman

How much resin did you use and how much pressure ? Since there is no fiberglass between your wood and your base, could it be possible you squeezed out too much?

Likely problems

Pressure: Too much, too little, or not even

Resin too little or kicked too fast, did you wet both surfaces?

Poor mold conformity maybe

Re: White spots showing through base material.

Posted: Thu Feb 23, 2023 4:21 pm

by SSSGAV

Jonrezz wrote: ↑Tue Nov 29, 2022 5:58 am

yeah I agree with chrismp - in addition to his question - are you providing a way to "bleed" excess epoxy? think of how a typical ski squeezes excess expoxy out the sides when pressed - these could also be epoxy pockets from excess having nowhere to go.

Lots of epoxy squeezes out the sides and ends. It is not trapped by any means.

Re: White spots showing through base material.

Posted: Thu Feb 23, 2023 4:23 pm

by SSSGAV

chrismp wrote: ↑Wed Nov 30, 2022 3:18 am

SSSGAV wrote: ↑Mon Nov 28, 2022 2:17 pm

Hydraulic cold press.

Could be a couple of things then. Your pressure might not be even enough (it's hard to get mold surfaces even and matching perfectly) - to mitigate this, you could use a thin layer of soft material (silicone foam sheets work well as epoxy doesn't stick to them) in the press on top of the base material to get a more even pressure distribution.

Another reason might be your epoxy already kicking before it gets into the press. Check the working time of your epoxy and compare that to how long it takes you to get everything into the press after mixing the epoxy. However, this is not an exact science as working time is usually stated for a mix of 100 grams in a cup - so if you mix significantly more than this and leave it in the cup, it will go off quicker and on the other hand spreading the epoxy on the workpiece will prolong working time if it hasn't already started kicking (i.e. getting too warm).

We have tried many of these things and did manage to get rid of the white pockets. We ended up using less pressure, more resin, and silicone sheets. The result looks great, unfortunately we are still ending up with some delamination! Again, we're flame treating, cleaning with alcohol, abraiding, etc.

Re: White spots showing through base material.

Posted: Fri Feb 24, 2023 6:07 pm

by vinman

Maybe add some fiberglass veil between you layers to hold resin??

Re: White spots showing through base material.

Posted: Wed Mar 01, 2023 12:31 am

by chrismp

There are some things you could try (or a combination). Many epoxies are quite brittle, so adding a bit of flexibilizer can help with delaminations. Make sure to test if the flexibilizer works with your epoxy on a sample!

And as already suggested adding some sort of filler to hold the epoxy, such as fiberglass veil or cotton flocks, should help too.

Re: White spots showing through base material.

Posted: Fri Apr 26, 2024 11:14 am

by evlskis

I'm sure the OP figured this out by now, but a couple of things to add.

Flame treating with the wrong fuel/air mix can be worse than not flame treating your UHMW, at all. Delam city - learned it the hard way. I don't see that introducing air pockets while curing under pressure, because it should be obvious during layup that your epoxy is beading up and rolling off the plastic.

No idea why the OP isn't using some kind of fiber between the wood and I guess base material? We do the same thing, but pressing thicker sheets of sidewall UHMW to 5mm thick sheets of hardwood to produce sidewall stock that will stay bonded to core blanks through the milling process. We cut the composite sidewall material into narrow strips and I have never noticed air pockets between the layers. If I did, I would assume I had not used enough epoxy, because we're already using high pressure and heat to squeeze out everything we can before it becomes a solid.

Iif your molds aren't true, but you're okay with whatever comes out matching the surface you're pressing against, then try more pressure. If you don't care about adding weight or waste, try using a more generous hand with the epoxy.