OK I'm not gonna create another post about screen printing, might as well keep all the info in the same place... so here I go ! (if this post need to be moved to another section let me know...)

I'm giving screen printing (for topsheets) a 2nd try right now.

I'm using the Nazdar ADE serie epoxy ink + snowboard catalyst, pretty common ink to use..

For reference I gave screen printing a try about 4 year ago because my workshop landlord was screenprinting t-shirts.. he helped a lot ! Back then I was using the old duraclear topsheet from Crown Plastics (the thick one). Keep aside the difficulty to learn screen printing using epoxy ink on a 6ft long screen and using a 14in wide squeegee, this attempt was almost a failure and this way of dealing with the graphics was rejected because this supposedly clear topsheet material was not. Basically if you applied pure black ink, once the topsheet is laminated on a pair of skis it ends up more dark blue than black (I already mentioned that in other topics).

The other material available in small quantities for screenprinting back then was the Isosport clear topsheet, which is a great material.. but very pricey ! so it's a no go for me.

In the last few years Crown Plastics started selling a new product, the Duravision 5050, it's kinda cheap, I don't expect it to be as durable as the isosport clear nylon, but it's way thinner than the previous Cown Plastics topsheet and it's announced as "clear". I'm giving it a try !

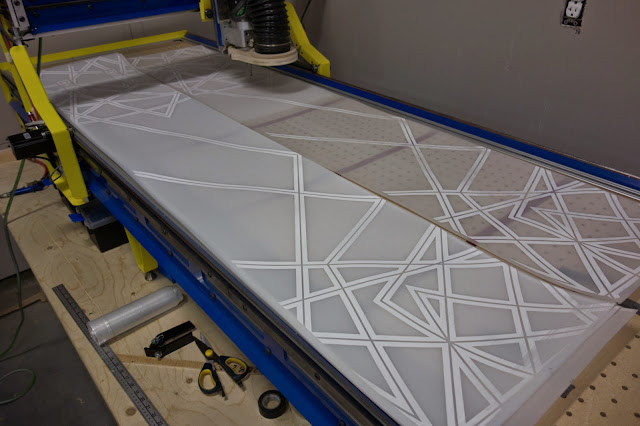

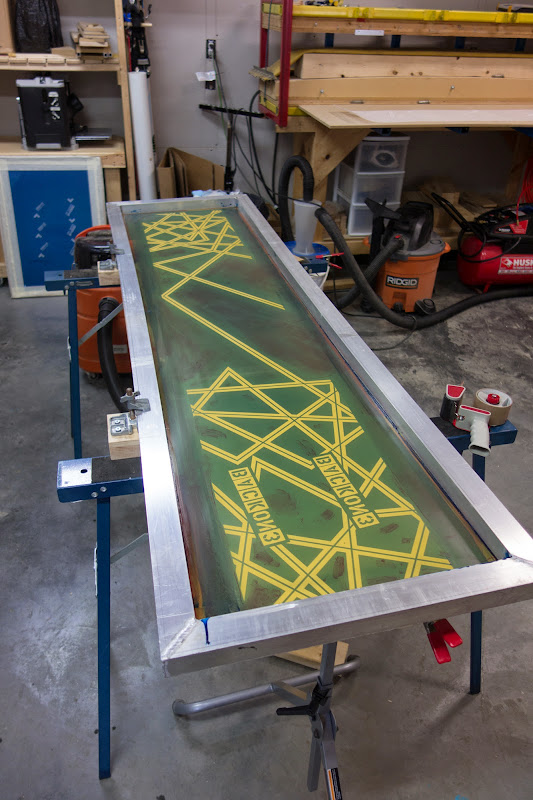

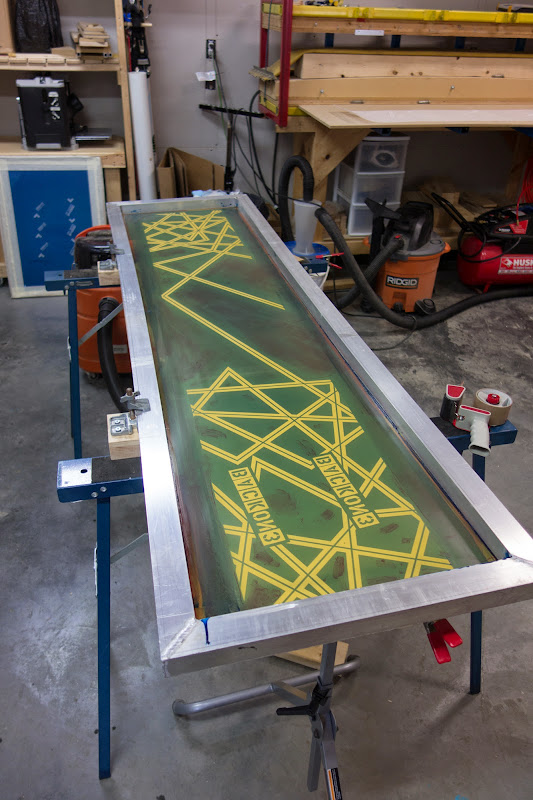

I had a new screen made to update my graphics, bought some new squeegees, got some ink samples, rebuilt my old vacuum table... here I go !

As I said first, screen printing is something 90% new for me. I understand the way it works and I made lots of research regarding how I'm supposed to work... but I know there is a significant learning curve before you can print something really well, especially considering the dimensions of the materials we're working with...

Yesterday was my first try : I took 3 pieces of Duravision (I was feeling confident) and mixed enough ink for 3 topsheets, here's how it ended up :

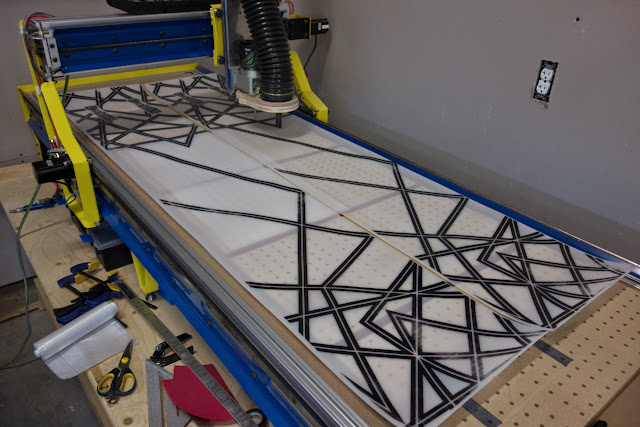

- I messed up with the ink viscosity, it was ways too thick so basically it was a hassle to flood the screen.. meaning when the time comes to apply pressure on the squeegee to print, some areas are OK, but some are really missing some ink ! when I saw that I tried to apply a 2nd coat... WRONG ! messed up again with such a thick ink so basically the 2nd print is slight off compared to the 1st one... + there is still some ink missing in some spots !

I had a lot of ink ready, I thought the 2nd topsheet could not be worse.. it ended up the same... and so did the 3rd ! I'm gonna be able to use them all but it's definitely far from what I call "good quality topsheets".

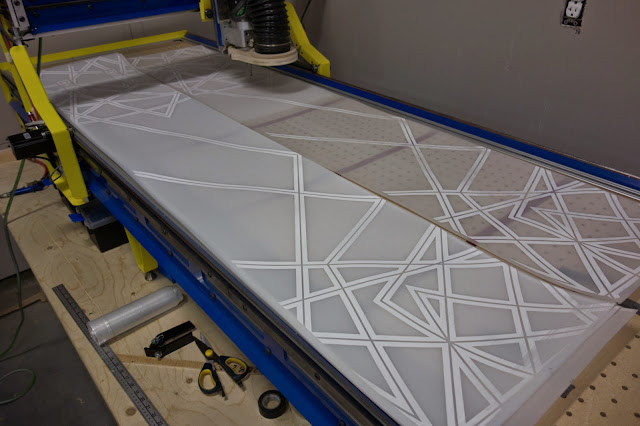

On a positive note the topsheet material looks OK, my first coat was with white ink, it looks like a very nice real white through the topsheet material. Tomorrow I'll try the black ink : with the screen (I have to improve how I use the squeegee) and also on the topsheets I already printed white, but on those ones I'll just apply the ink with a paint brush since it's "only" the black background. So hopefully tomorrow night I'll know if the material is really clear !

Another problem I had to deal with (and I'm gonna have to deal with it again tomorrow) is the vacuum table that holds the topsheet material.

The topsheet comes in rolls, when you lay it flat it's not actually flat it's wavy so it's a real PITA to position it on the vacuum table + the suction is bad so it doesn't hold well. I'm gonna have to find a good idea for that because the real problem is that while you're switching the "just printed" material to a new piece of topsheet and you're messing up trying to put the material at the right place and be sure the vacuum holds it kinda tight, the ink on the screen slightly cures, gets thicker, thus making the next print a hassle ! Next time, as soon as I receive a roll of topsheet material I'll cut it in 2 meter sections and store it perfectly flat !

Some pics from yesterday for good measure :

Ben