Sometimes ski building is like a golf swing, some days you're right on the mark and you think you do the exact same thing the next time, but you end up in the woods.

Bent Green Things 13/14

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

skidesmond

- Posts: 2337

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

Man that's frustrating. It's totally fixable. I'd clean out the gap of any lose debris, wet out some vds, slide it in place if possible and re-press and use clamps to close the gap. Let it set over night.

Sometimes ski building is like a golf swing, some days you're right on the mark and you think you do the exact same thing the next time, but you end up in the woods.

Sometimes ski building is like a golf swing, some days you're right on the mark and you think you do the exact same thing the next time, but you end up in the woods.

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

QCM EMV0043 + ECA408, = 45min-1hr "pot life" (wont actually kick till it sees heat)

try that, it DOES look like you're getting premature epoxy curing.

either that, or you have a big void somewhere, like your material thicknesses are off, and your sidewall is not seeing pressure.

two higher spots (from side to side) would stop the third spot from seeing pressure, if that makes any sense. Or if the higher(thicker) area is closer to the sidewall, the cat tracks will tip in the opposite direction.

try that, it DOES look like you're getting premature epoxy curing.

either that, or you have a big void somewhere, like your material thicknesses are off, and your sidewall is not seeing pressure.

two higher spots (from side to side) would stop the third spot from seeing pressure, if that makes any sense. Or if the higher(thicker) area is closer to the sidewall, the cat tracks will tip in the opposite direction.

Doug

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

are you pressing both skis at once? if one is skewed lengthwise, compared to the other... then the thicknesses are off, you need to get your material thicknesses dialed, and ensure when doing 2 ski that they are registered in your cassette/mold perfectly, if one moves then your thicknesses that the press sees will be compromised.

Doug

Nii: excellent ideas!

I do press both at the same time. and they were lined up very well. But it is something that should absolutely be focused on.

I use super sap CPM/CPL.

http://www.entropyresins.com/sites/defa ... CPM_v5.pdf

Which has a 50 min pot life. The layup took me just under 40min (I have a timer going during layup).

what does premature epoxy curing look like? Perhaps I didn't mix it well enough this time? Maybe all the CF that i put in this ski soaked up more epoxy and "starved" the edges?

I do press both at the same time. and they were lined up very well. But it is something that should absolutely be focused on.

I use super sap CPM/CPL.

http://www.entropyresins.com/sites/defa ... CPM_v5.pdf

Which has a 50 min pot life. The layup took me just under 40min (I have a timer going during layup).

what does premature epoxy curing look like? Perhaps I didn't mix it well enough this time? Maybe all the CF that i put in this ski soaked up more epoxy and "starved" the edges?

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Your thinkin wrong. This is a spring back issue. U tryed to press with no rabbit making the base concave but u have bonding issues with the uhmw so.... the ski delams and ends up flat. No rabbit=no bueno. Pretty simple. Just my opinion after 100 pair or so.

sammer wrote: I'm still a tang on top guy.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

MM, explain what you mean about composite not edge to edge. Are you just asking if he cut the carbon to fit inside the edge instead of using a rabbett?

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

That is a very worthy point.MontuckyMadman wrote:Your thinkin wrong. This is a spring back issue. U tryed to press with no rabbit making the base concave but u have bonding issues with the uhmw so.... the ski delams and ends up flat. No rabbit=no bueno. Pretty simple. Just my opinion after 100 pair or so.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

I was thinkin also maybe if the composite on top the core was not edge to edge and he had premature epoxy kick yoi could see a bridgeing and d lam there also.

Carbon is tricky if useing in large pieces cause its 3 times the stiffness of glass so many issues can arise.

Armchair qtr back says its the rodent...rabbit or lack there of.

Carbon is tricky if useing in large pieces cause its 3 times the stiffness of glass so many issues can arise.

Armchair qtr back says its the rodent...rabbit or lack there of.

sammer wrote: I'm still a tang on top guy.

yup! i trust your opinion greatly! you have always stated that a rabbet is a must. this pair was my first that I didn't do it. I figured the 9oz of carbon would make up the space. i guess I was wrong...MontuckyMadman wrote:. Just my opinion after 100 pair or so.

yes, I ran 22Oz tri-ax top and bottom. the Carbon was within the core, it didn't go out to the UHMW.

Is there a way to determine if epoxy starts to kick?

Thanks again guys, your ideas are much appreciated.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

I would back fill that with gflex from west. The jbweld is brittle. You can see all the edge teeth on the base. That auto means rabbit not deep enough or in this case no rebate at all. Did you sand and smooth and flame you sidewalls?

I'm thinkin the carbon didn't bond well to the core either with that amount of delam.

Badass setup you got btw.

I don't think those sidewalls will last too long skiin.

Did you epoxy the sidewalls on to the core or another means?

Hope they hold for a while.

I'm not really sure how the big boys avoid a rabbit with the inegra or other poly based composite. All the skis I have cut open from others have a rabbit or shoulder or rebate.

Maybe useing real soft wood like balsa or sometimes even poplar or pine can press into the edge teeth but they don't come out with those imprints I don't think.

I always thought you could drop some kevlar in there but I think some on here have tried it.

Proper prep of the uhmw is key if you wanth to avoid this rebate I assume.

I don't think it was a premature kick but I really don't know and I dont think u can tell other than the resin is gelling in ur hands and cup and glass.

Did u use rubber I assume?

I'm thinkin the carbon didn't bond well to the core either with that amount of delam.

Badass setup you got btw.

I don't think those sidewalls will last too long skiin.

Did you epoxy the sidewalls on to the core or another means?

Hope they hold for a while.

I'm not really sure how the big boys avoid a rabbit with the inegra or other poly based composite. All the skis I have cut open from others have a rabbit or shoulder or rebate.

Maybe useing real soft wood like balsa or sometimes even poplar or pine can press into the edge teeth but they don't come out with those imprints I don't think.

I always thought you could drop some kevlar in there but I think some on here have tried it.

Proper prep of the uhmw is key if you wanth to avoid this rebate I assume.

I don't think it was a premature kick but I really don't know and I dont think u can tell other than the resin is gelling in ur hands and cup and glass.

Did u use rubber I assume?

sammer wrote: I'm still a tang on top guy.

okay I get the dumb ass award for the week... thanks MM

first black line: side wall material

second black line: VDS

then white fiberglass

notice anything??? ahhhhh DING DING DING. this idiot didn't sand and flame treat. you can actually see the planner "cut marks" got pressed into the VDS but no sticking...

I know this is a great lesson for me and hopefully others can learn from $$$ error...

watched Meet the Robinsons with the kids tonight, take away lesson: "keep moving forward" and "celebrate failures"!

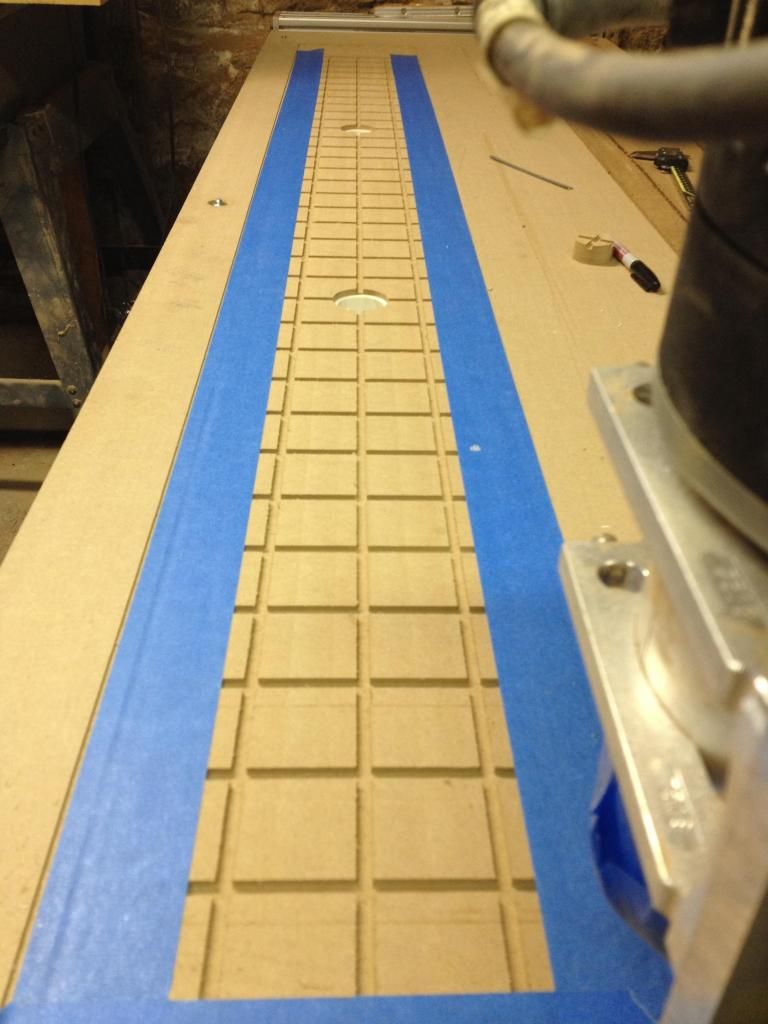

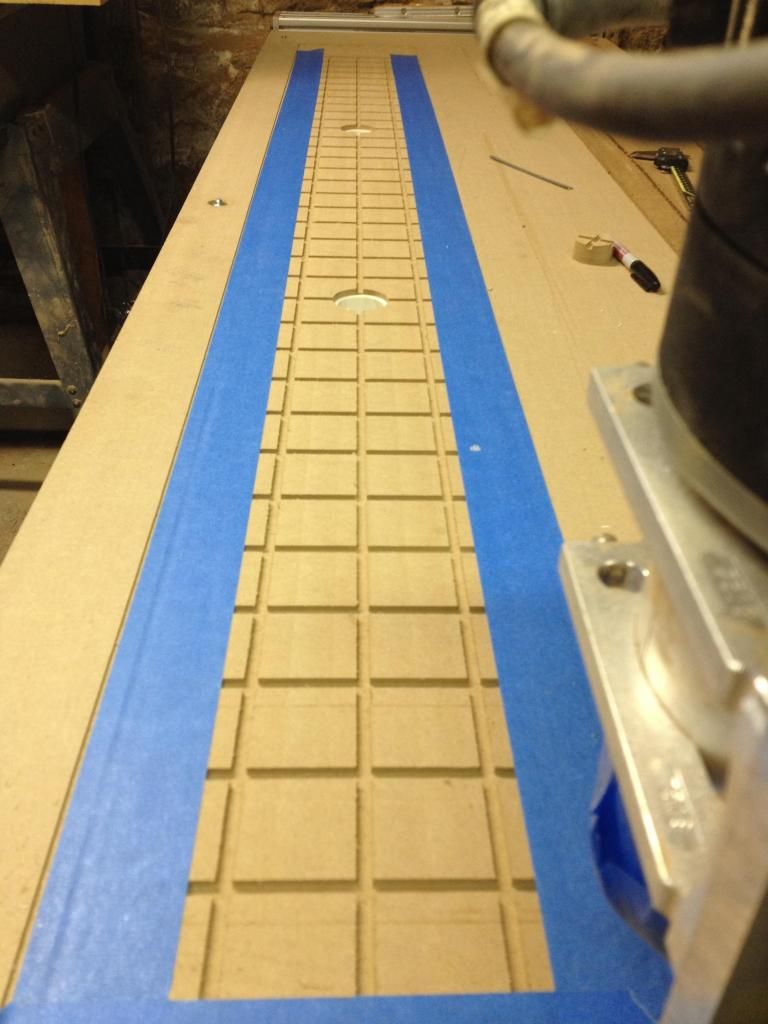

vacuum table completed... I think. I'm thinking of adding two more ports in the front and back, opinions welcome:

first black line: side wall material

second black line: VDS

then white fiberglass

notice anything??? ahhhhh DING DING DING. this idiot didn't sand and flame treat. you can actually see the planner "cut marks" got pressed into the VDS but no sticking...

I know this is a great lesson for me and hopefully others can learn from $$$ error...

watched Meet the Robinsons with the kids tonight, take away lesson: "keep moving forward" and "celebrate failures"!

vacuum table completed... I think. I'm thinking of adding two more ports in the front and back, opinions welcome:

yup that would do it. though one to learn that way but i bet you never make that mistake again.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

Hey Gang,

I've almost got this CAD/CNC thing licked. man, what a learning curve. Where the heck is MonkeyCAM??? ;-) So close. I figure a few more days of testing. I feel like I'm constantly reinventing the wheel, wish one of you CNC nurds lived in the Taxachusets area.

Anyone care to give me some BETA on bamboo core profile, these cores have a different flex than my ash/poplar cores.

My test core came out at 2.2-12-2.2. I'm going with 22oz tri--ax. I like a stiff ski (my screwed up pair are perfect flex) so I'm going to put some Carbon in this pair too. I'm also going with BB sidewalls i'm hanging my hat up on UHMW (until i can crank out some dependable skis). Any ideas would be great. cheers.

I've almost got this CAD/CNC thing licked. man, what a learning curve. Where the heck is MonkeyCAM??? ;-) So close. I figure a few more days of testing. I feel like I'm constantly reinventing the wheel, wish one of you CNC nurds lived in the Taxachusets area.

Anyone care to give me some BETA on bamboo core profile, these cores have a different flex than my ash/poplar cores.

My test core came out at 2.2-12-2.2. I'm going with 22oz tri--ax. I like a stiff ski (my screwed up pair are perfect flex) so I'm going to put some Carbon in this pair too. I'm also going with BB sidewalls i'm hanging my hat up on UHMW (until i can crank out some dependable skis). Any ideas would be great. cheers.

-

skidesmond

- Posts: 2337

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

I'm not ready to attempt CNC yet. Kudos to you for taking a crack at it.skimann20 wrote:Hey Gang,

I've almost got this CAD/CNC thing licked. man, what a learning curve. Where the heck is MonkeyCAM??? ;-) So close. I figure a few more days of testing. I feel like I'm constantly reinventing the wheel, wish one of you CNC nurds lived in the Taxachusets area.

Anyone care to give me some BETA on bamboo core profile, these cores have a different flex than my ash/poplar cores.

My test core came out at 2.2-12-2.2. I'm going with 22oz tri--ax. I like a stiff ski (my screwed up pair are perfect flex) so I'm going to put some Carbon in this pair too. I'm also going with BB sidewalls i'm hanging my hat up on UHMW (until i can crank out some dependable skis). Any ideas would be great. cheers.

It's amazing how much stiffer CF will make a ski. I've only played around with 9.4 oz uni and it's really really stiff. I used CF in my daughters skis and I'm worried it will be too stiff for her to bend the ski and that was a 3in strip the length of the ski. We'll see...