Page 1 of 5

Juke 2013/2014

Posted: Tue Aug 13, 2013 11:32 am

by JukeSnowboarding

Thought I would finally start a log and make a resolution to keep up with it through this coming season of builds.

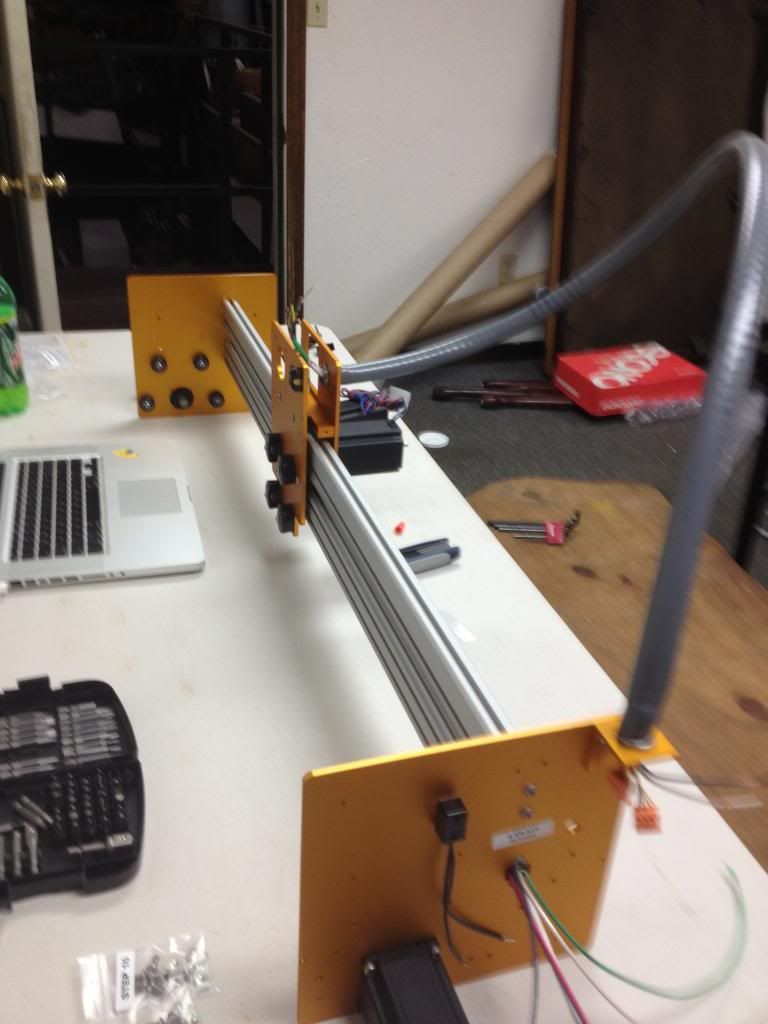

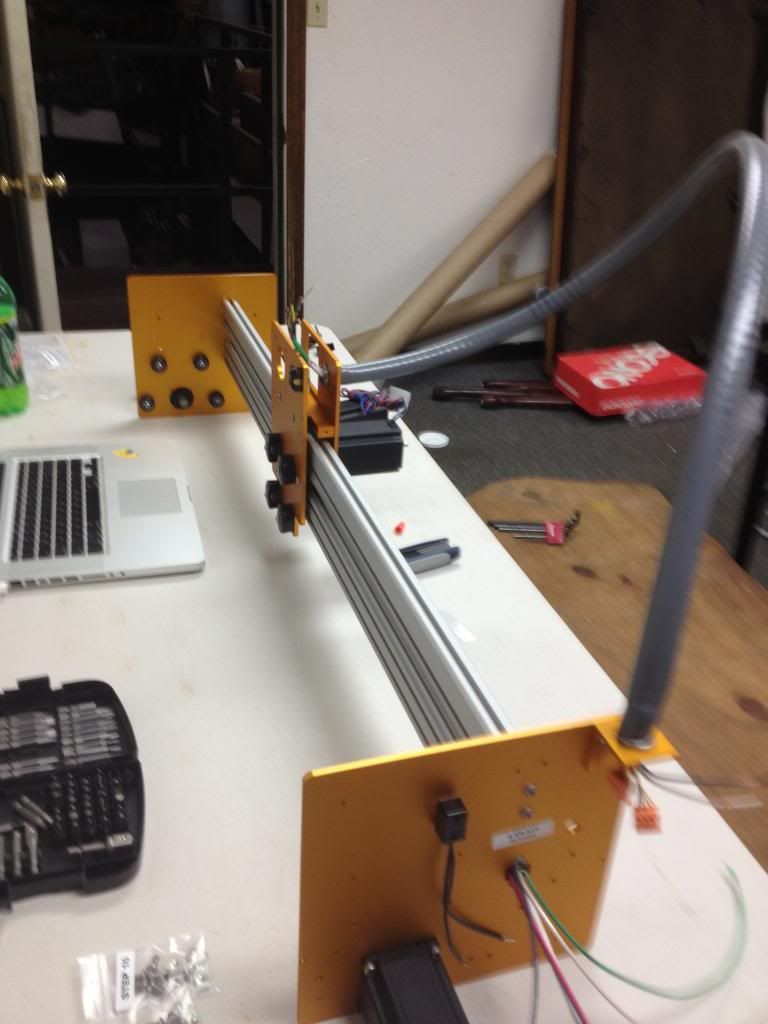

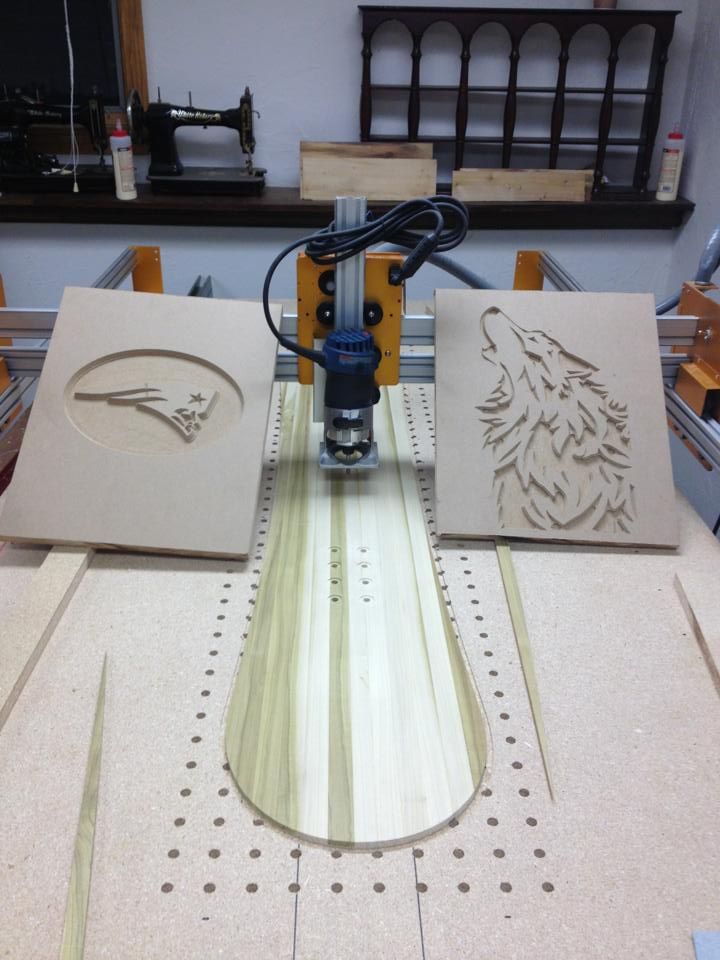

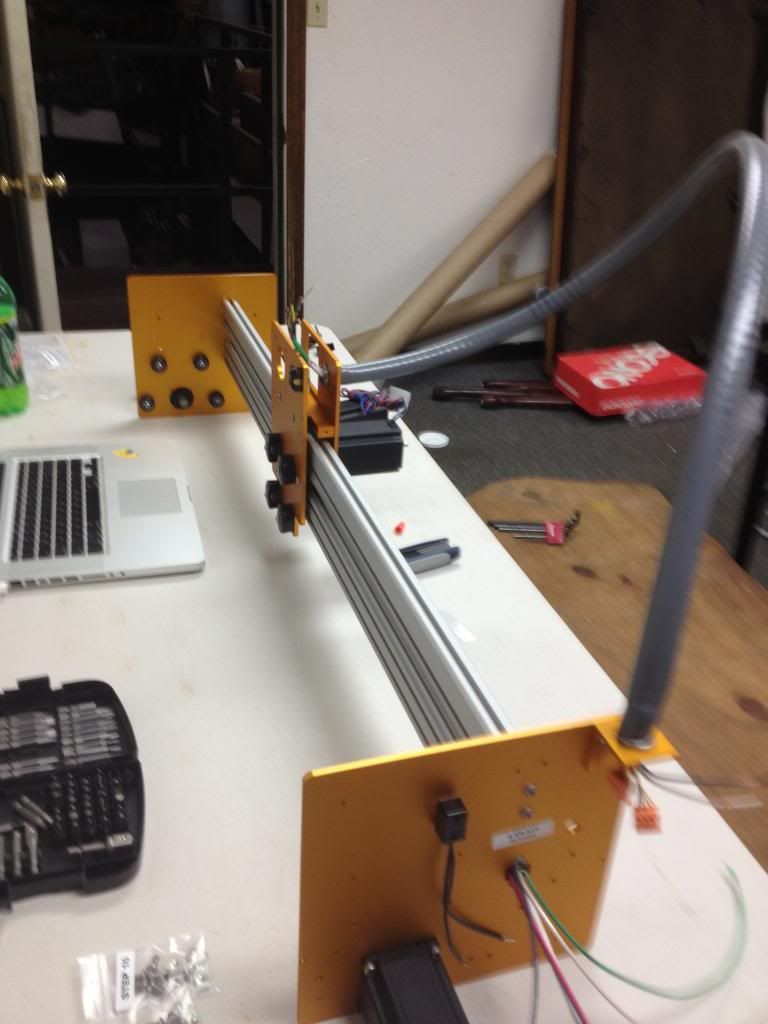

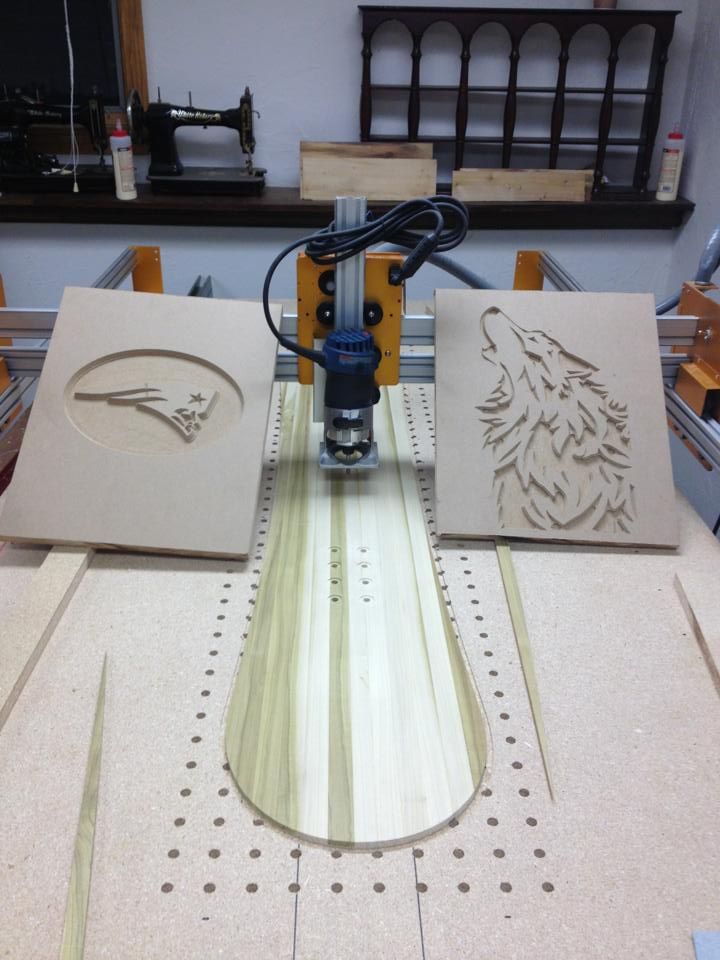

Just graduated college in May, so I thought this might be one of the best times to blow some money on something yet unknown. So I jumped on the grenade that is the CNC Mogul and so far it has worked out great.

Everything came packed very nicely and was accompanied by a disk with written directions and 3d modeling directions for the build.

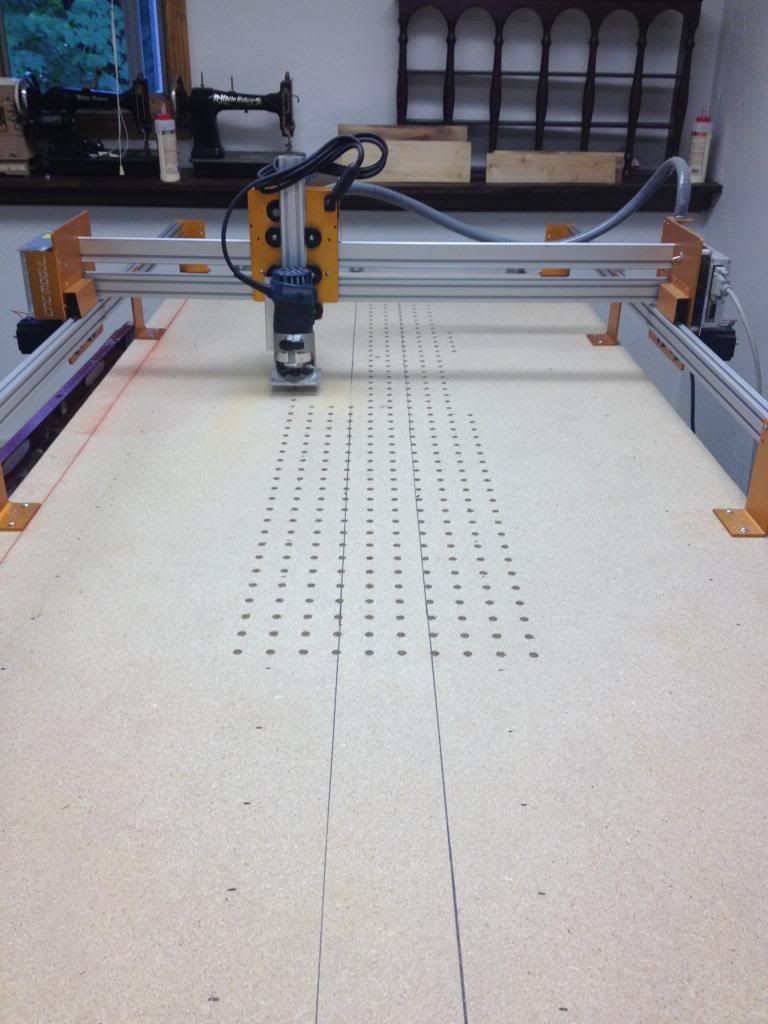

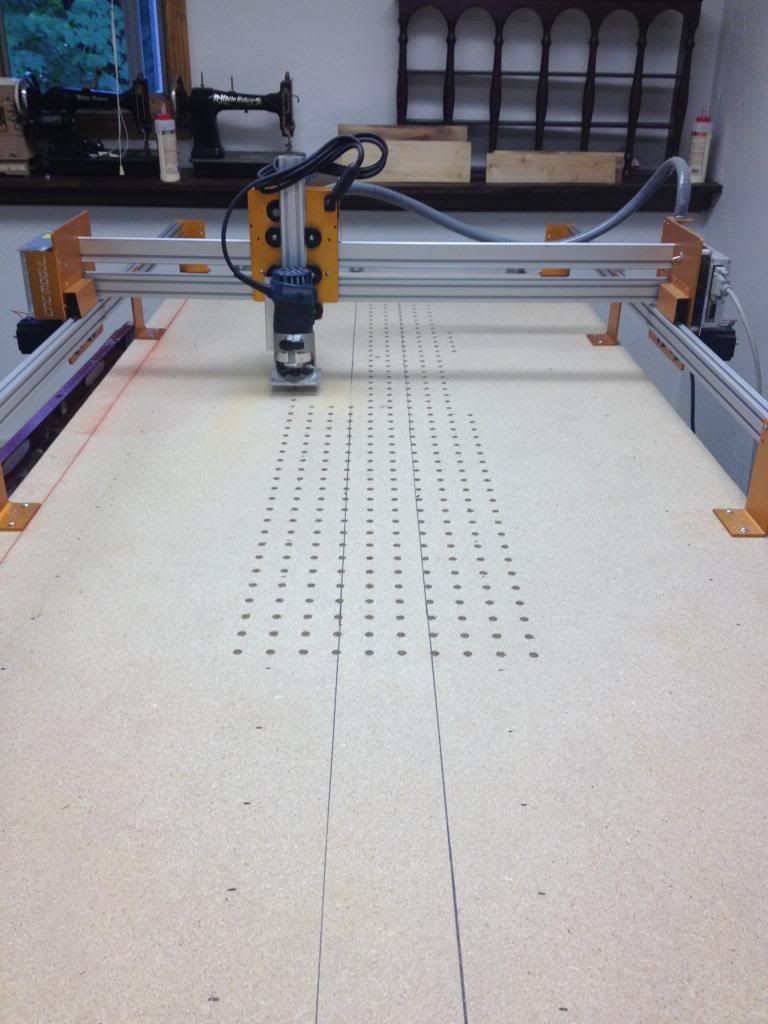

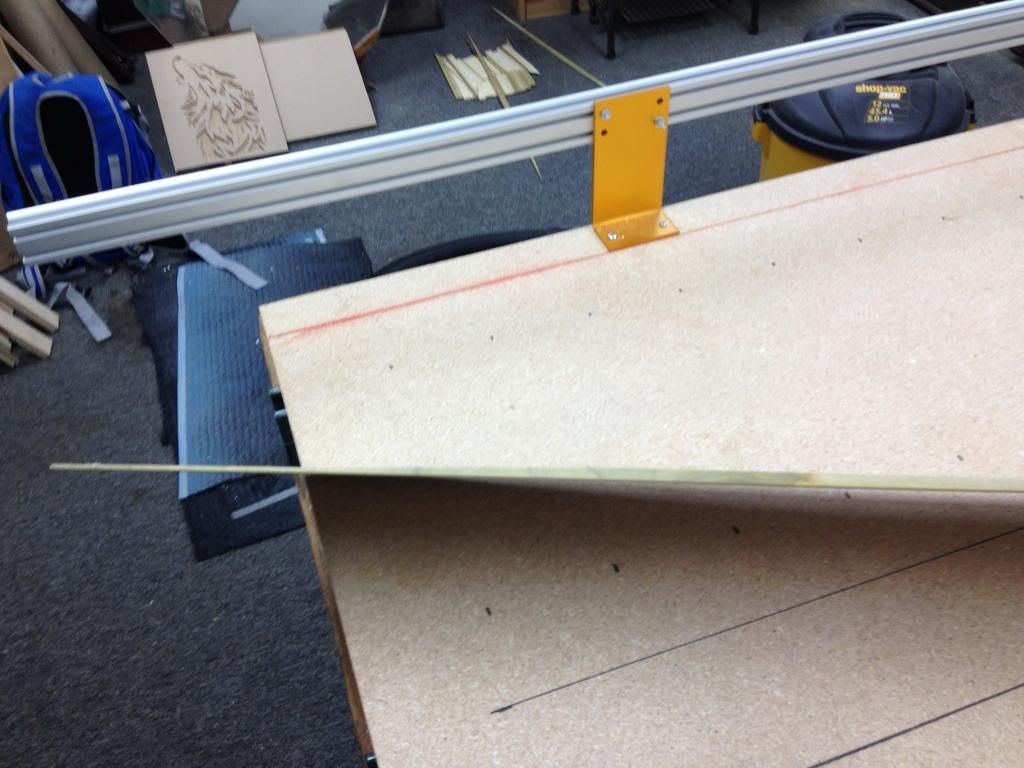

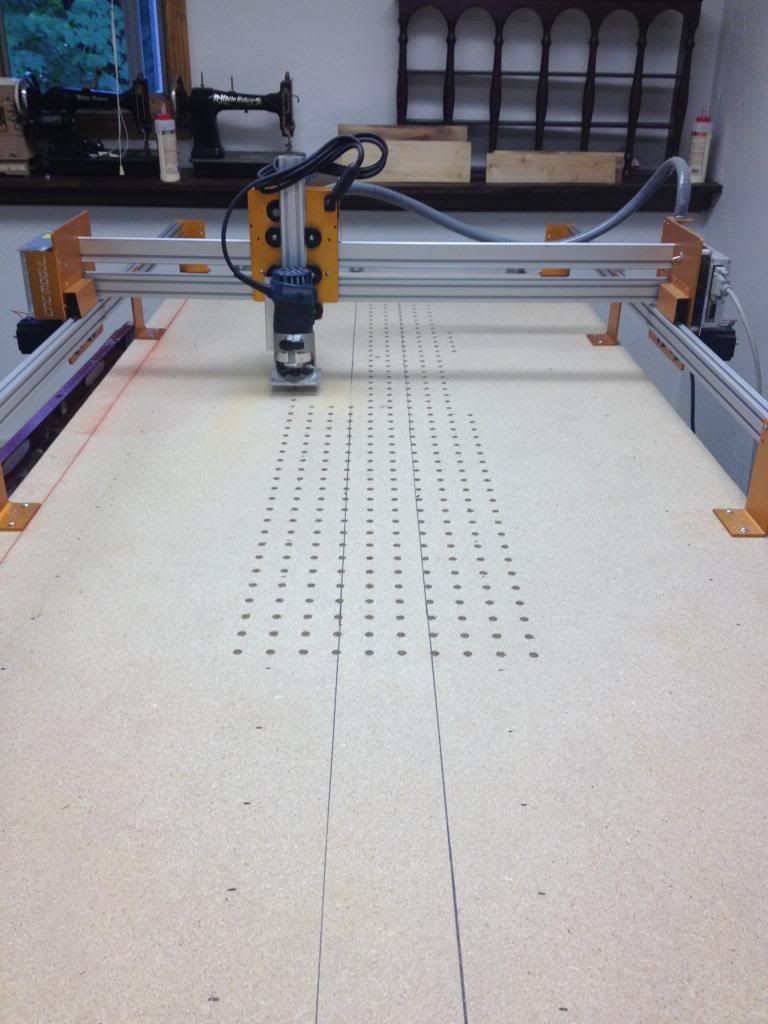

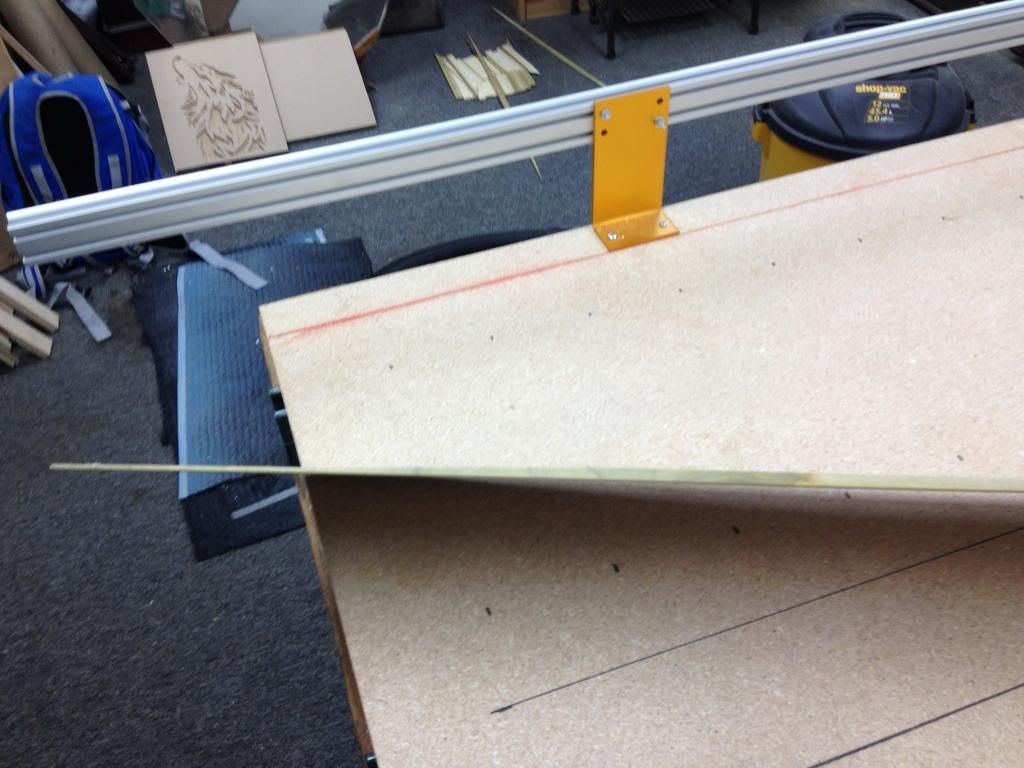

After a couple hours the machine started to take shape. And after viewing Sean's video from Donek Snowboards I started on the vacuum table.

As the table started to take shape I was still skeptical with the holding power it would produce especially when profiling, after my experience with the router bridge method.

I decided to drill only enough holes to spread past the width and length of the majority of my cores. In the future I could add more for bigger projects. Turning on the vacuuming and laying down a core blank, it took a lot of force to move the core from the vacuum hold down. I was very satisfied with the force.

Posted: Tue Aug 13, 2013 11:36 am

by twizzstyle

That looks great!

No need to seal the wood inside that chamber? Seems like you would lose a bit of suction from the porosity of the wood?

Posted: Tue Aug 13, 2013 11:46 am

by JukeSnowboarding

I forget to mention I had zero knowledge on anything related to CNC machines other than what I have read here, and the templates I have had made in the past.

My first cut with the machine was terrifying, but came out better than I could have thought. And after the first weekend I started to get the hang of it.

So I cut my first practice core out of a scrap blank I had lying around.

And after staring at my computer for hours, I decided to try profiling the core without sidewalls to start. With limited bits I was able to get a product just as good as my router bridge method had been producing.

The process will need fine tuning, especially with the bits and as I learn more about machining and tool customization.

I lined up some scrap tip spacer with the nose of the board, and it was a perfect fit around the nose.

Next up will be to profile and full core with sidewalls and cut some tip spacers to see how everything fits together.

Posted: Tue Aug 13, 2013 11:48 am

by JukeSnowboarding

@Twizz So far so good I have not noticed any loss in suction, unless I leave extra holes exposed. After buying the Mogul you are invited to a owners group, so I have been bouncing ideas off of Sean at Donek while I learn what I can about using this for boards.

Posted: Tue Aug 13, 2013 3:21 pm

by skidesmond

Wow talk about jumping in with both feet! Very impressed with you've done so far. Nice Patriots logo.

(edit) I checked out the CNC Mogul website. As CNC machines goes it seems very cheap. Can you give us some feedback on it? That is definitely in my price range.

Posted: Tue Aug 13, 2013 3:55 pm

by MontuckyMadman

What software did you use to cad model the core profile and plot tool paths?

Posted: Tue Aug 13, 2013 4:46 pm

by JukeSnowboarding

@skidesmond For the like 0 I know about CNC machines it seems pretty good for the price. I know some people were worried because it was so cheap, but for everything I have tried so far it has done it fine. I will have to do more tests to tell for certain. Also my shop area is in Northborough Ma, so like 10 minutes down route 9 east of Worcester. If you ever wanted to see the machine before your purchase.

@MontuckeyMadman The Mogul actual came with aspire and all the other vectric programs. And for the cad I just used Snocad since I am still learning how to use the more in depth software. My first try on the profile was done with the fluting tool path going from the center thickness down to the nose/tail over a linear couple inches. Just used a wide straight plunge bit. with paths that over lapped. Most likely better ways of doing this, but it was my first weekend ever using a machine like this.

Posted: Tue Aug 13, 2013 5:14 pm

by MontuckyMadman

hmm, sno cad was able to export a 3d core profile? I cant believe this came with aspire its a $1500 program by itself.

Posted: Tue Aug 13, 2013 5:19 pm

by JukeSnowboarding

I had to tell the tool paths where to go. No 3d profile. And I dont know much about programs, but I have Aspire 3.0 from the disk I got with the machine. I haven't questioned it.

Posted: Tue Aug 13, 2013 5:24 pm

by sammer

Juke...

Are you using their $38 router?

How big of a bit are you using?

How long did it take the machine to profile your core?

How many passes?

Thanks,

sam

Posted: Tue Aug 13, 2013 5:35 pm

by JukeSnowboarding

@Sammer I am using a Bosch Colt which is like between $99-120 depending on where you get it. On the Mogul site they sell that cheap router, but there is also a page with a list of about 10 routers that work perfect on it from Craftsman to Dewalt.

I need to buy a larger bit. The one I had for the first try was only a 1/2 so it ended up taking like 20 minutes I think for a side. I can tell you how long the whole core takes once I get the proper bit, and profile the core all at once. Im thinking with the correct bit it can be done with everything in under a 1/2 hour.

Which is loads better for me, after the router bridge method.

Posted: Tue Aug 13, 2013 5:59 pm

by MontuckyMadman

Im not sure how you told it where to go without a 3d model to work from.

Any other details appreciated.

Posted: Tue Aug 13, 2013 11:02 pm

by chrismp

Nice! Which size did you buy? It would be great if you could make some tests on precision and accuracy of the machine in wood (i.e. take scrap pieces of wood and have it machine them down to the same thickness and compare the pieces with a caliper).

Posted: Wed Aug 14, 2013 11:59 am

by Buz

Northboro?!?? I am from Northboro...just moved in June. I have plans to get my shop back up and running for the coming winter, had a baby in December so was forced to take a season of building off. sending PM

Posted: Wed Aug 14, 2013 12:26 pm

by skidesmond

JukeSnowboarding wrote:@skidesmond For the like 0 I know about CNC machines it seems pretty good for the price. I know some people were worried because it was so cheap, but for everything I have tried so far it has done it fine. I will have to do more tests to tell for certain. Also my shop area is in Northborough Ma, so like 10 minutes down route 9 east of Worcester. If you ever wanted to see the machine before your purchase.

......

PM sent.