temperature averaging and controller

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

temperature averaging and controller

in many discussions related to heat mentioned that temperature is very throughout the cassette and difference in the reading of the temperature come from sensor location.

Why not install multiple sensors with one controller and do temperature averaging? this way tips and tales temperature will not not run away if sensor located in the middle or center part don't get up to the temperature at all if sensor located at the tip/tail

Why not install multiple sensors with one controller and do temperature averaging? this way tips and tales temperature will not not run away if sensor located in the middle or center part don't get up to the temperature at all if sensor located at the tip/tail

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

I haven't used thermal blankets for pressing yet, but I work lab scale and industrial ovens heating elements. I do not think an averaging function for multiple inputs is necessary in the PID controller. The reason for this is that when you finally get the blanket to the temperature to what you want, and you measure 50 degrees different from end to end, or end to middle or whatever.... there isn't much you can do about it in terms of control. I'd say it'd be better to just heat the thing up a few times and record the temperatures of the additional thermocouples and then pick your target temperature accordingly. The other way to play this game is to move your control TC to an area that seems to be in a good average spot.

If you really want to deal with thermal non-uniformity, you can try adding insulation in areas that seem colder, or you can design your blanket in such a way where there is more winds of wire in areas that seem to get colder.

If you really want to deal with thermal non-uniformity, you can try adding insulation in areas that seem colder, or you can design your blanket in such a way where there is more winds of wire in areas that seem to get colder.

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

I'm not building/buying PID/SSR controller I'm going with ETC from RancoMontuckyMadman wrote:sure do you have a pid that will take numerous TC's?

Sounds expensive and a PITA to put in all those TC's every time.

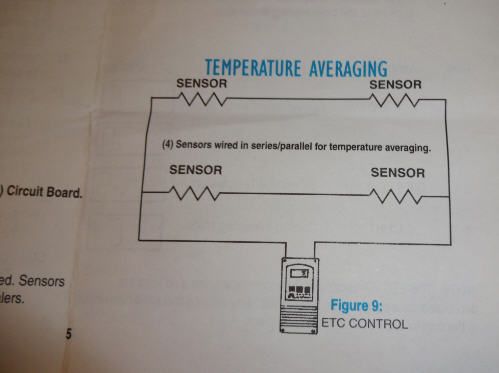

in paperwork it has diagram where additionalTCs splice into parallel for temperature averaging.

Doesn't looks it should be expensive or difficult. To confirm I need to talk to specialist

you are correct. But to my understanding temperature averaging with multiple probes might give better control indirectly where different temperatures in different area kept at the same level all the time.JSquare wrote: The reason for this is that when you finally get the blanket to the temperature to what you want, and you measure 50 degrees different from end to end, or end to middle or whatever.... there isn't much you can do about it in terms of control.

Reason I start this thread because after discussion on the subject with two specialists on controls,at two separate occasions, after explaining what I'm doing both of them immediately suggested temperature averaging with controller like a better way compared to single TC.

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

ETC sounds good, but it won't give you zoned heating or compensate for issues with the heat map.

If the heating blanket is giving you a consistent heat map (same temp at different locations), then the choice is between zoned cooling or zoned heating. Either option requires multiple TC providing independent readings

It sounds like your press is going to give you zoned cooling, so it might just be a matter of tweaking the results. Zoned cooling is cheaper, but not as flexible.

The issue is individual to each heated press ... but at around 50oC, there is a tendency for the body of the ski to heat up more quickly than the tips. Below 50oC, the issue is heavily influenced by the thermal capacity of the materials involved.

If the heating blanket is giving you a consistent heat map (same temp at different locations), then the choice is between zoned cooling or zoned heating. Either option requires multiple TC providing independent readings

It sounds like your press is going to give you zoned cooling, so it might just be a matter of tweaking the results. Zoned cooling is cheaper, but not as flexible.

The issue is individual to each heated press ... but at around 50oC, there is a tendency for the body of the ski to heat up more quickly than the tips. Below 50oC, the issue is heavily influenced by the thermal capacity of the materials involved.

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

Richuk you many steps ahead of me. I'm not completely understand what you're trying to say.Richuk wrote:ETC sounds good, but it won't give you zoned heating or compensate for issues with the heat map.

If the heating blanket is giving you a consistent heat map (same temp at different locations), then the choice is between zoned cooling or zoned heating. Either option requires multiple TC providing independent readings

It sounds like your press is going to give you zoned cooling, so it might just be a matter of tweaking the results. Zoned cooling is cheaper, but not as flexible.

The issue is individual to each heated press ... but at around 50oC, there is a tendency for the body of the ski to heat up more quickly than the tips. Below 50oC, the issue is heavily influenced by the thermal capacity of the materials involved.

Zoned cooling, zoned heating

It sounds like your press is going to give you zoned cooling==> you need to explain.

I'm barely keeping my head above the water trying to get the next step and have no idea what kind of the problem waiting for me there

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

Eh? I've got no real input to this thread (I place my thermocouple such as to measure the temp of the blanket, and assume the blanket has uniform heating, good enough), but this comment of yours caught me off guard a little bit.Richuk wrote:but at around 50oC, there is a tendency for the body of the ski to heat up more quickly than the tips.

Why would the body (where there is more mass) heat up quicker than the tips?

(sorry for the distraction in the thread)

MR - I don't think I'm steps ahead, I've just done it more often - so far! Anyway, I will try my best to explain what I have encountered. As you appreciate, certain materials conduct and certain materials insulate and I thought I read that only the tip moulds are made of MDF in your press and the rest of the mould is metal. So when you apply heat, the metal mold is going to conduct the heat and reduce the efficiency of the blanket. Inversely, the MDF tip mould is going to insulate the blanket and retain more of the heat being applied. This shouldn't be a problem, provided the effect is not too great, as the body of the ski should catch up and produce an even cure i.e. the tips and body of the ski hit 80oC (or whatever temp required), at the same time.

Zoned heat implies that you would have separate heat blankets for the various sections along the ski. Each heat mat would have its own TC and controller. They all start and stop at the same time, but they might end up using different amounts of energy to raise the temperature of cassette (this is what Tony was talking about). The adjustment being necessary due to how the press conducts or insulates at any particular point or the different thermal capacities of the materials within the ski and or the amount of epoxy being used in a specific area.

Twizz, I think the over-riding issue is to do with the different thermal capacity of the differing materials? I'm not sure reading the blanket is the way to go. I thought we needed to measure the temperature of the cassette (tool) and ideally the laminate - if you are setting up the press for production.

Zoned heat implies that you would have separate heat blankets for the various sections along the ski. Each heat mat would have its own TC and controller. They all start and stop at the same time, but they might end up using different amounts of energy to raise the temperature of cassette (this is what Tony was talking about). The adjustment being necessary due to how the press conducts or insulates at any particular point or the different thermal capacities of the materials within the ski and or the amount of epoxy being used in a specific area.

Twizz, I think the over-riding issue is to do with the different thermal capacity of the differing materials? I'm not sure reading the blanket is the way to go. I thought we needed to measure the temperature of the cassette (tool) and ideally the laminate - if you are setting up the press for production.

When heating from one side heat conduction becomes very important. From two sides I think maybe less so. Realistically the glue (epoxy) is very superficial in the ski and is separated from the blanket by the same thickness of material (ie. topsheet or base ) along the length of the ski (assuming blankets on both sides). As time goes by I guess in the thinner tips the lower laminate is more quickly influenced by heat from the top blanket and vice versa than in the thick middle where the core blocks heat flow.

With one blanket this is very pronounced as whichever side you have the blanket on will reach temp much faster and the other side takes longer and different parts , like the middle on the opposite side, take even longer and may never reach the set temp value (depending on heat loss/materials etc)

Practically it seems the two blanket with 2 separate controller approach is fine. I think the 2 controllers are key as each blanket has a different thermal environment to achieve its rate if heating in.

I have however thought about a blanket with 3 zones (tip, mid, tail) that has three separate tc's and controllers to better take into account the change in thickness of the ski. This is a large capital investment + much more to go wrong though.

With one blanket this is very pronounced as whichever side you have the blanket on will reach temp much faster and the other side takes longer and different parts , like the middle on the opposite side, take even longer and may never reach the set temp value (depending on heat loss/materials etc)

Practically it seems the two blanket with 2 separate controller approach is fine. I think the 2 controllers are key as each blanket has a different thermal environment to achieve its rate if heating in.

I have however thought about a blanket with 3 zones (tip, mid, tail) that has three separate tc's and controllers to better take into account the change in thickness of the ski. This is a large capital investment + much more to go wrong though.

Don't wait up, I'm off to kill Summer....

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Falls - epoxy is the key element within the construction of the ski. With a heated cure, the temperature difference can be as much as 8oC. If your tips are at 80oC and the body is at 88oC, then you have a major problem, as the rule of thumb provides that increasing the temp by 10oC cuts the cure time in half. Inversely, if the body is at 80oC and the tips show 72oC ... then the tips won't cure properly. Ramp rate is a factor here too.

The point I'm seeking to make is that MR is looking to smooth out a potential temperature disparity without all the facts. I'm sure if he goes with ETC, he'll get a good result ... but the it isn't the answer to temperature variation within the press or eliminating hot spots. The ETC is a good way of smoothing out the temperature and not letting a hot spot develop. I would go with it and use a digital temperature probe to measure for temperature variation at points along the cassette. If there are none - happy days!

The point I'm seeking to make is that MR is looking to smooth out a potential temperature disparity without all the facts. I'm sure if he goes with ETC, he'll get a good result ... but the it isn't the answer to temperature variation within the press or eliminating hot spots. The ETC is a good way of smoothing out the temperature and not letting a hot spot develop. I would go with it and use a digital temperature probe to measure for temperature variation at points along the cassette. If there are none - happy days!

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

I am with MM it doesn't matter what temperature on the blanket. TCs have to be on the cassette.MontuckyMadman wrote:Doesn't matter what temp the blanket is.

You need the temp of you r laminate.

Simply trusting you have good heat conduction is silly.

Just put the tcs on the bottom cassettse and top cassette.

Richuk

I was told, what you describing as a zone heat. Not the way to go and temperature averaging with one controller better way. I asked why and was told " it's become complicated, difficult to control, you do not want to know all details, trust me on this one" this person I trust. He set up temperature control systems for living.

problem of an even heat is a completely different. Blanket should provide even temperature over entire surface. Certain sections of the ski will heat up faster but overall temperature of laminate should be all the same. If it's not,problem elsewhere. Again if blankets work properly the only other reason for an even temperature is a heat loss. Additional problem with an even heat is an even thermal expansion of laminate components

heat loss can be solved 2 ways.

1. Have more powerful heating system which overcome heat loss and provide same temperature over entire surface at the same time. Best way here hot water heating system, steam if you need higher temperature, oil if temperature over 400°F need, glycol if you want to do heating and cooling.

2. With elected blanket the only way is add insulation. Add as much as needed until cattracks will be cold at full heat or at least barely warm, same goes for the bottom blanket

also wouldn't be a bad idea to cover opening with insulation to.

BTW uninsulated surface size of the blanket is very big and will have a substantial amount of heat loss.

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

I asked same question before didn't get answerfalls wrote:What is an ETC compared to a PID controller?

http://www.skibuilders.com/phpBB2/posti ... a12f50bbaa

Ranco ETC I'm buying compared to PID is complete unit no need to build one. It have limitations up to 8 A at 240 V 16A at 120 V. Cannot be programmed like PID can. That's about it.

I don't want to build PID controller and deal with programming off the unit got myself ETCs

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison