Living-room project... CNC !

Posted: Tue Nov 13, 2012 8:57 am

Hey all,

I'm gonna have a lot of time inside the house for the next few month (I'm about to being a dad) so I had to find something to do while not changing diapers but still having an eye on "mini-Ben_Mtl"... Moving my skibuilding equipment in the kitchen was not an option, not to mention the charming noise of a planer of router shaping some cores or the delightful smell of Epoxy... -> it's time to build a CNC !!

I spent the last few weeks working on a nice CNC concept, spend countless hours on CNCZone and finally found something I liked. At one point I found a journal about a very nice and innovative CNC machine, I had my starting point and spend a lot of time checking every detail on every picture on this thread so I could design my machine from something that actually works (and I don't even feel guilty about trying to replicate and adapt to my needs this nice machine.. I guess I'm used to it as I do it all the time with skibuilding processes/videos).

First, give Ceasar what belongs to Ceasar.. here is my inspiration :

http://www.cnczone.com/forums/diy-cnc_r ... build.html

It's a very nice looking machine, the concept is great and I always wanted to give it a shot with sheetmetal to make a CNC...

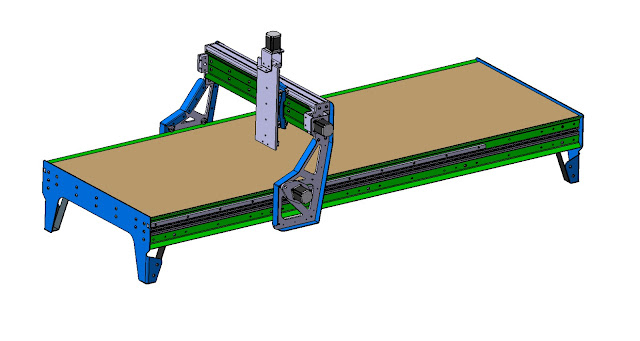

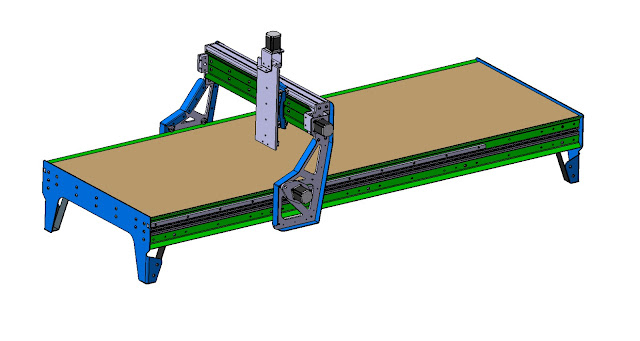

For all of you pics whores, here is the latest 3D I have of my future machine :

I made it so I have a 7'x2' cutting area, the skeleton is 80-20 extrusions, the rest is bent sheetmetal and a few aluminum parts.

The linear motion is basically V-Groove bearings rolling on steel rails, Rack and Pinon drive on the X axis (one stepper on each side of the gantry), ACME screws for Y(5-start) and Z (single-start).

I have to say the critical part was to figure out how to install the rack&pinion drive for the X axis.. I'm still unsure of my solution so before I commit to what I've done and have te parts lasercut, I'm gonna wait till I get the rails to check if everything could work.

I just ordered my stepper kit (4x NEMA 23 steppers + Gecko G540) + some parts needed for the R&P and ACME drive, plus all the V-Groove bearings.

I'm also about to order a few laser-cut / bent parts to validate if the 45degree rails concept is working with the "not-so-close" tolerances I can get from local manufacturers. If it's not working I'll buy some specific v-groove rails.. but it's gonna be more expensive...

That's it for now, if you have any comment/recommendation/question feel free to post !

I'm gonna have a lot of time inside the house for the next few month (I'm about to being a dad) so I had to find something to do while not changing diapers but still having an eye on "mini-Ben_Mtl"... Moving my skibuilding equipment in the kitchen was not an option, not to mention the charming noise of a planer of router shaping some cores or the delightful smell of Epoxy... -> it's time to build a CNC !!

I spent the last few weeks working on a nice CNC concept, spend countless hours on CNCZone and finally found something I liked. At one point I found a journal about a very nice and innovative CNC machine, I had my starting point and spend a lot of time checking every detail on every picture on this thread so I could design my machine from something that actually works (and I don't even feel guilty about trying to replicate and adapt to my needs this nice machine.. I guess I'm used to it as I do it all the time with skibuilding processes/videos).

First, give Ceasar what belongs to Ceasar.. here is my inspiration :

http://www.cnczone.com/forums/diy-cnc_r ... build.html

It's a very nice looking machine, the concept is great and I always wanted to give it a shot with sheetmetal to make a CNC...

For all of you pics whores, here is the latest 3D I have of my future machine :

I made it so I have a 7'x2' cutting area, the skeleton is 80-20 extrusions, the rest is bent sheetmetal and a few aluminum parts.

The linear motion is basically V-Groove bearings rolling on steel rails, Rack and Pinon drive on the X axis (one stepper on each side of the gantry), ACME screws for Y(5-start) and Z (single-start).

I have to say the critical part was to figure out how to install the rack&pinion drive for the X axis.. I'm still unsure of my solution so before I commit to what I've done and have te parts lasercut, I'm gonna wait till I get the rails to check if everything could work.

I just ordered my stepper kit (4x NEMA 23 steppers + Gecko G540) + some parts needed for the R&P and ACME drive, plus all the V-Groove bearings.

I'm also about to order a few laser-cut / bent parts to validate if the 45degree rails concept is working with the "not-so-close" tolerances I can get from local manufacturers. If it's not working I'll buy some specific v-groove rails.. but it's gonna be more expensive...

That's it for now, if you have any comment/recommendation/question feel free to post !