Ski building awesomeness 12/13

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

gotcha, you definitely need the bars to go beyond the edge of the hoses, to pinch them off.

We have a 16" bladder and square bar with about 24 bolts thru them. With tons of washers and silicone, its probably $100 in materials just used to pinch off the bladders.

Also, some people like to fold the end over on itself, then clamp off that fold. Just preference, ours isnt like that, and has been functional for years. HOpe i'm not jinxing it.

We have a 16" bladder and square bar with about 24 bolts thru them. With tons of washers and silicone, its probably $100 in materials just used to pinch off the bladders.

Also, some people like to fold the end over on itself, then clamp off that fold. Just preference, ours isnt like that, and has been functional for years. HOpe i'm not jinxing it.

Doug

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

I think 1.5" is too much. You saw how I did the fire hose, metal sticking out barely 1/2". How many bolts you going to use? I used five par firehose where last fairly close to the age. If angle line already cut its to late to regret just do it and see what's happened. One suggestion before you do bolting use C clamps to clamp firehose and pressurized it to check air inlet for leaks. It pain in the.... to take it all apart if inlet need to be tight upskimann20 wrote:

No I'm worried that the air will push past the end of the angle iron. It's literally right to end of the hose. I would prefer at least 1.5" past the ends and bolt it down. Does that make sence?

quick update on my progress, finally some wood work, enough of all this steel work... I got busy making the bottom mold.

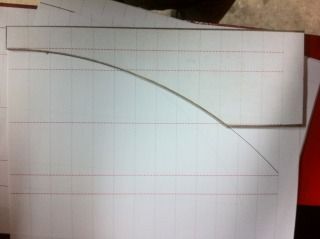

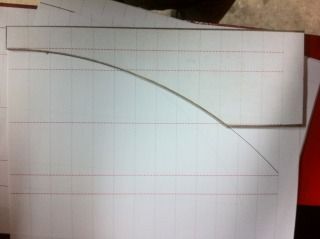

templates made. I started with 1/8" lamboard

then I traced it on the MDF 3/4" that I'm going to use for the mold. these will be my actual template. I used my bandsaw to make a rough cut out.

Nailed the 1/8" template to the MDF and used a router to trim them out:

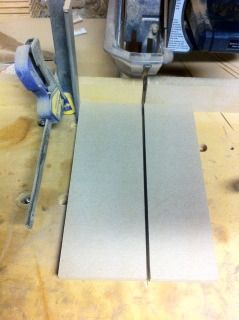

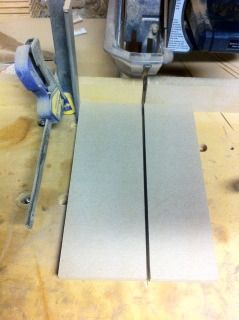

cut my blanks out for all the tips. used a stop block on the radial arm saw.

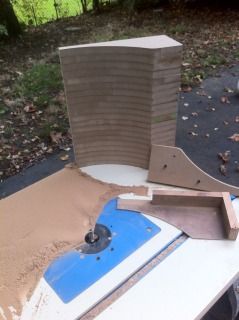

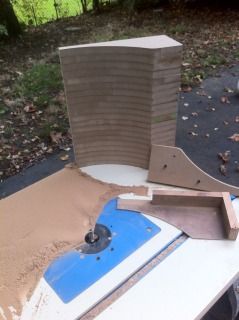

all of them piled up!

I traced a line on the square blanks with my template and rough cut out all of the tip molds. my calibrated eye isn't too shabby.

Here is my jig I used to rout them out:

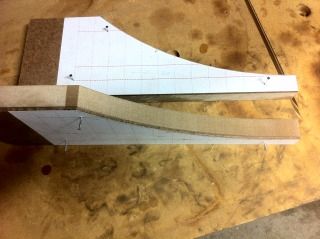

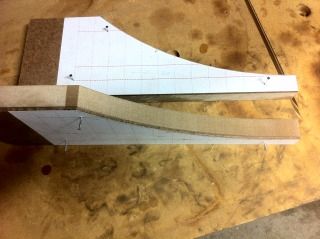

top part is the template and the bottom section is the part that will get cut down. you can see my calibrated eye was almost too good. this is precut.

that being said, while making that jig I had a spring clamp snap loose and hit me in the eye. Went to the emergancy room and everything checked out okay. I'm a big believer in wearing your safety glasses, I had them one just minutes before while drilling and took them off to do the layup. man I'm lucky!

okay back on track...

here is one of the finished stacks with the jig and template.

Question:

How long are you all making the bottom section of your mold? I was thinking 7'???

templates made. I started with 1/8" lamboard

then I traced it on the MDF 3/4" that I'm going to use for the mold. these will be my actual template. I used my bandsaw to make a rough cut out.

Nailed the 1/8" template to the MDF and used a router to trim them out:

cut my blanks out for all the tips. used a stop block on the radial arm saw.

all of them piled up!

I traced a line on the square blanks with my template and rough cut out all of the tip molds. my calibrated eye isn't too shabby.

Here is my jig I used to rout them out:

top part is the template and the bottom section is the part that will get cut down. you can see my calibrated eye was almost too good. this is precut.

that being said, while making that jig I had a spring clamp snap loose and hit me in the eye. Went to the emergancy room and everything checked out okay. I'm a big believer in wearing your safety glasses, I had them one just minutes before while drilling and took them off to do the layup. man I'm lucky!

okay back on track...

here is one of the finished stacks with the jig and template.

Question:

How long are you all making the bottom section of your mold? I was thinking 7'???

-

skidesmond

- Posts: 2337

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

I've gotten a bad reputation with my buddies about me and safety gear. I am good about safety glasses and ear protection 99% of the time I swear, but it only takes that 1% to set you up for some serious injuries. Glad to hear your eyes are ok!

A few weeks ago I had a metal spark hit my eye (I was wearing eye protection that time, it bounced around the safety glasses). The piece of steel embedded itself to my eye and rusted. I didn't notice it until 2 days later when I woke up with my eyelid swollen completely shut. Went to the eye doctor, and after taking off the metal shard, he had to use this dremel tool thing to grind the rust off my eyeball. Gross.

(the mold pieces look great!)

A few weeks ago I had a metal spark hit my eye (I was wearing eye protection that time, it bounced around the safety glasses). The piece of steel embedded itself to my eye and rusted. I didn't notice it until 2 days later when I woke up with my eyelid swollen completely shut. Went to the eye doctor, and after taking off the metal shard, he had to use this dremel tool thing to grind the rust off my eyeball. Gross.

(the mold pieces look great!)

skidesmond: thanks. that's what I was going to go with but it's always nice to hear what others have done. 190 is crazy long but I have some crazy buddies out in Wyoming and Colorado that might put in a crazy order...

twizzstyle: hear that! I had a wood chip in my eye 6 months ago and got real scared. so all drilling and grinding sawing ect i have protection on. but who would have thought a spring clamp would have blown loose and hit me in the eye??? like you said its the 1% of the time that nails you!

I'm happy with the mold pieces, wood working is my zen.

twizzstyle: hear that! I had a wood chip in my eye 6 months ago and got real scared. so all drilling and grinding sawing ect i have protection on. but who would have thought a spring clamp would have blown loose and hit me in the eye??? like you said its the 1% of the time that nails you!

I'm happy with the mold pieces, wood working is my zen.

Good to hear your eye is ok. I have said it before and I'll say it again. Everyone should get one of these masks, especially for working with MDF.

They are made by 3M and somewhat pricey but worth every penny. You can buy replacement film for the lens to keep your vision perfect unlike most safety glasses. Cartridges are fairly cheap too. I searched ebay and got all of this for about $100.

They are made by 3M and somewhat pricey but worth every penny. You can buy replacement film for the lens to keep your vision perfect unlike most safety glasses. Cartridges are fairly cheap too. I searched ebay and got all of this for about $100.

Okay, so lets say I build a pair of skis for "More" at 193cm because he got taller... i would need a mold that is 193cm+180mm for the extra mounting backing on my tip and tail molds+the offset he wants to push his boot center back: say 9cm (this would push the front running length of the ski 9cm longer if I put put the apex of the camber at boot center. So I would need a total mold length of 220cm? Am I correct on this? If someone could verify that would help a lot. Or am I all off and barking up the wrong tree?

cheers,

~Brad

cheers,

~Brad

Depends how you mount your moulds I guess. We pretty much machine a camber board for every ski, and mount tip, camber, and tail board to a flat chip board that slides in and out of the press. The total mould length for the 191 ski is about 205ish I think and I reckon we could reduce that substantially down into the mid to high 190's (I'm not sure that rounding off the moulds all neatly on the back side is doing anything for us).

Wouldn't it make more sense to machine your camber board offset for a boot centre in a traditional sort of place, ~55%? then you won't have to offset all your skis.

Wouldn't it make more sense to machine your camber board offset for a boot centre in a traditional sort of place, ~55%? then you won't have to offset all your skis.