Page 4 of 14

Posted: Sat Mar 31, 2012 7:09 pm

by MadRussian

skidesmond wrote:I say go for it and let us know how it performs. I made a pair of 86mm wide skis this year and loved them. About the same side cut, around 16.5. Great for big carving turns, and super smooth and stable.

What's you core dims going to be?

2.5 tip; 7mm at220mm; 10mm at center; 9 at 450 from tale and 3 tale

Posted: Sun Apr 01, 2012 5:17 am

by MadRussian

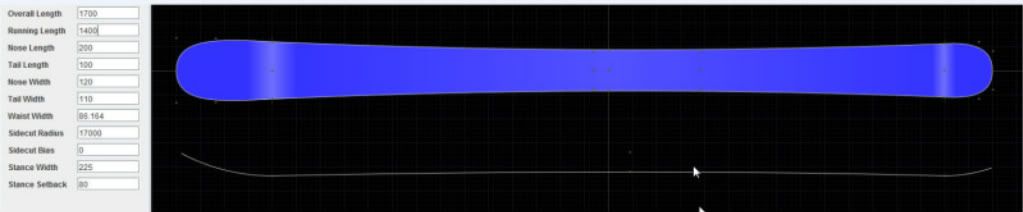

more changes

Overall Length 1700

Running Length 1400

Nose Length 200

Tail Length 100

Nose Width 120

Tail Width 110

Waist Width 86.164

Sidecut Radius 17000

Sidecut Bias 0

Stance Width 225

Stance Setback 80

Nose Height 49

Tail Height 17

Camber 8

Camber Setback 46

Posted: Sun Apr 01, 2012 5:21 am

by MadRussian

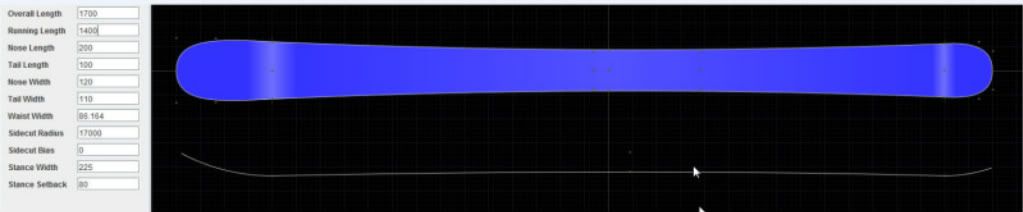

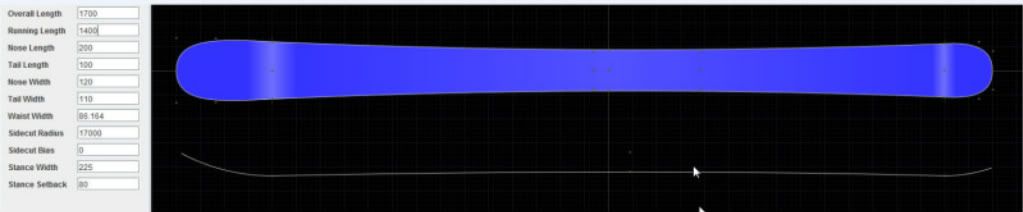

more changes

Overall Length 1700

Running Length 1400

Nose Length 200

Tail Length 100

Nose Width 120

Tail Width 110

Waist Width 86.164

Sidecut Radius 17000

Sidecut Bias 50

Stance Width 225

Stance Setback 80

Nose Height 49

Tail Height 17

Camber 8

Camber Setback 50

Posted: Sun Apr 01, 2012 5:38 am

by vinman

Looks better, more traditional shape. camber might be set back a bit too far still. I'm not sure the 55% formula works that well for shorter skis... But you can go with it I guess. It just seems like 8cm behind the center is a lot on a 170 cm ski.

But unless you want a soft ski I'd think about beefing up your core to something like 2-11-2.

I personally dislike soft skis and make my cores 2.2-12-2.2 with a maple-poplar laminate. Tis gives a fairly stiff ski hen using 22 oz glass.

Posted: Sun Apr 01, 2012 4:38 pm

by MadRussian

started to work on bottom mold.

MDF creating enormous amount of dust, even outside respirator is a must. definitely this hobby not the easy one... should have try checkers first

cut first piece for the template

cutting whole bunch

Posted: Sun Apr 01, 2012 4:55 pm

by MadRussian

Vinman wrote:Looks better, more traditional shape. camber might be set back a bit too far still. I'm not sure the 55% formula works that well for shorter skis... But you can go with it I guess. It just seems like 8cm behind the center is a lot on a 170 cm ski.

I'll change it for 30 mm for the final version

But unless you want a soft ski I'd think about beefing up your core to something like 2-11-2.

I personally dislike soft skis and make my cores 2.2-12-2.2 with a maple-poplar laminate. Tis gives a fairly stiff ski hen using 22 oz glass.

most of my skis are fairly stiff.

My plans to make core not with even taper more like in two steps which would create thicker middle section longer but without flat space

2.5 tip; 7mm at 220mm; 10mm at center; 9 at 450 from tale and 3 tale

Posted: Sun Jul 08, 2012 5:27 pm

by MadRussian

Last a few days worked on mold almost complete top and bottom. Need little bit more sending to do and the top need only filler in the middle

drilling camber section 4 ribs at the time

Top was easy to do compared to bottom one

First time inflated with molds only 5 to 10 psi just to keep camber section straight. For some reason it got curled up and twisted and very uneven after ribs got bolted together. After couple hours under pressure look so much better

Posted: Mon Jul 16, 2012 3:13 pm

by knightsofnii

can i make a suggestion? see all those wood pieces you have above your top mold... all the 2x4 pieces and what not? To me, and i'm just going by what i see first glance, that looks like a giant frag grenade waiting to go off. I highly suggest you come up with something flat/solid to put in place of all those pieces to take up the slack.

We stacked about 6 sheets of 1/2" mdf under our bottom mold to take up the extra cavity space, and i'm nervous about that as it's not glued/bolted together.

Posted: Mon Jul 16, 2012 5:26 pm

by MadRussian

knightsofnii wrote:can i make a suggestion? see all those wood pieces you have above your top mold... all the 2x4 pieces and what not? To me, and i'm just going by what i see first glance, that looks like a giant frag grenade waiting to go off. I highly suggest you come up with something flat/solid to put in place of all those pieces to take up the slack.

We stacked about 6 sheets of 1/2" mdf under our bottom mold to take up the extra cavity space, and i'm nervous about that as it's not glued/bolted together.

This is temporary and only up to 5 PSI because my camber section didn't come out too well, after ribs got bolted together. It's start twisted a little but it gets flats under pressure. Got to figure out what to do with this problem. Last thing I want to make a new one

Posted: Mon Aug 13, 2012 3:16 pm

by MadRussian

1 step forward 2 step backwards.

After long thought decided to rebuild my profiling table to build it all including tabletop from metal. First step reinforcing frame. original frame was made from 1/8" wall 1" square tubing. Definitely not strong enough. This time I going to reinforce that with 1 inch U-channel. No welded only bolts to make sure all components stay in place. First time around frame got twisted like propeller after welding before cools off and get straight This time I don't want to take chances. Tabletop will be made from 1" thick steel plate. dimensions 8 foot long and 27 inches wide

Posted: Fri Aug 31, 2012 1:25 am

by MadRussian

I need advise.

This weekend going to cut cattracks.

How long? My mold 17 inches wide I am planning to make cattracks about 18" or maybe 19".Press 20" wide but I think this is too long.

How long is too long (wide)? 18 should be enough.... Building for the first time very frustrating

how wide cattracks and cassette should be in relation to the mold?

Posted: Fri Aug 31, 2012 4:26 am

by vinman

I'd go with just barely wider than your molds, maybe 18 inches.

Posted: Fri Aug 31, 2012 4:47 am

by ben_mtl

My mold is 17" wide, so is my cat-track. My casettes however are 16" wide (so I can have 3 pieces cut out of a 4x8 sheet.

Actually if I could I would make my casettes wider than the mold so I'm sure I don't have any excess epoxy squezzed out of the layup and ending up on the mold..

Posted: Fri Aug 31, 2012 10:55 am

by skidesmond

My press is 16inches wide and my cat track is 20inches wide. Remember you need some extra width on the cat track to be able to suspend (using bungy chords or springs..) the cat track when the hose is not inflated.

Posted: Fri Aug 31, 2012 3:05 pm

by MadRussian

Decided to go middle-of-the-road 19". Should be enough room to connect suspension system. It might be some problem here because steel supplier carry only 14gauge tubing. Going to need to go to get springs out of trampoline. Hope I need only one lol.

Had a few hours of free time today, cutting went faster than I expected almost finish all of it. Will have more time to work on profiling table