I figured posting an idea that failed is just as helpful as posting an idea that worked.

I've been wanting to use my band saw for profiling cores for a while. The planer works good, it just takes a while (we have a small planer) and makes a sawdust mess.

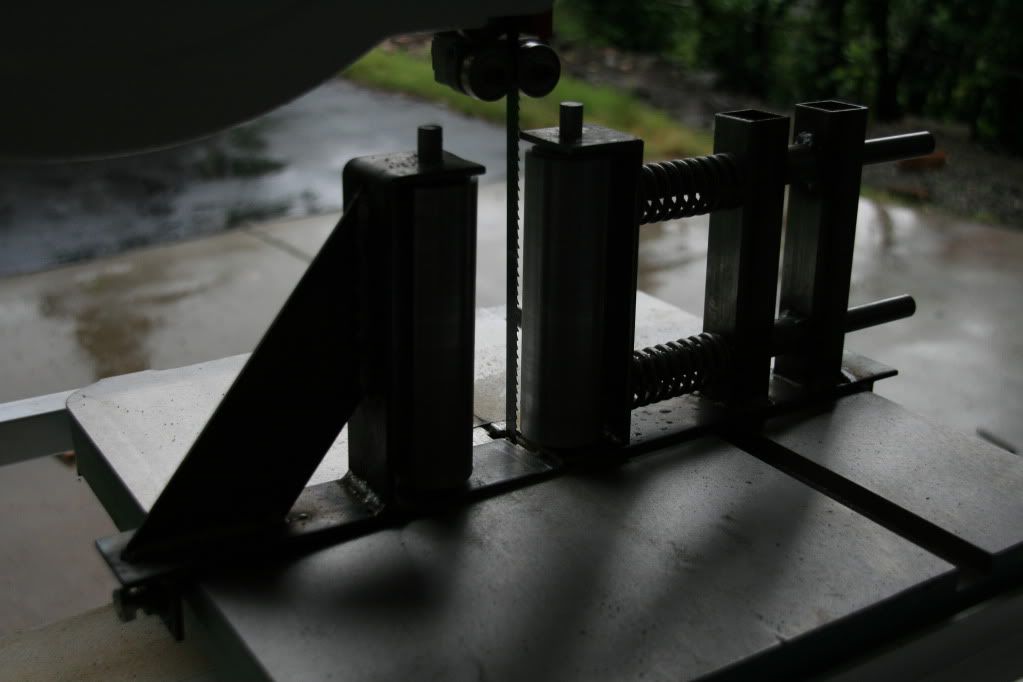

So I came up with this idea and made this jig thing a month ago or so.

Basically there is one fixed roller that is parallel to the blade, and one roller on springs. It works the same way as with the planer, you use a profile crib board and run it through the jig, the spring roller pushes the core into the crib board.

I think it would work great, were it not for my band saw. My band saw is pretty small (14" grizzly) and just isn't up for re-sawing wood that thick. I did a test cut with a 4" wide board, and about 3" in the blade had already wandered too much. I had the blade as tight as I could go too. Maybe with a wider/thicker blade it might do better, but I've accepted defeat and will just stick with the planer.

Still - if anybody has a bandsaw capable of re-sawing through 6" of wood, this might be a great tool.