I'm using douglas fir and ash. I bought a 4x4x96inch Douglas Fir post. The grain is very straight. I cut off the width I needed and put the rest in the rack for more skis later. I was tempted make the entire core from fir and use ash for the side wall to make a light ski but decided to use ash under the boot/binding area. The fir will be in the middle of the ski, in front and behind the binding area.

Trying a couple new things this time around. I'll be making the cores w/o using a planer crib or router bridge. I'm going to use my jointer. I'll plane the entire core down to 10mm, then use the jointer to make the taper, going from 10mm to 2.5-3mm. The binding area will remain at 10mm. I realize this will make the transition at the start of the taper rather sharp but I'll smooth it out w/ the belt sander.

I'll be using tip fill. Haven't decided if I'll try to use a solid piece of ash thinned to about 2.5 - 3mm or use some left over black p-tex.

Some pics from today:

Below are the pieces that will make of the center of the core for 1 set of the skis.

Getting ready for the glue up:

Dry fit:

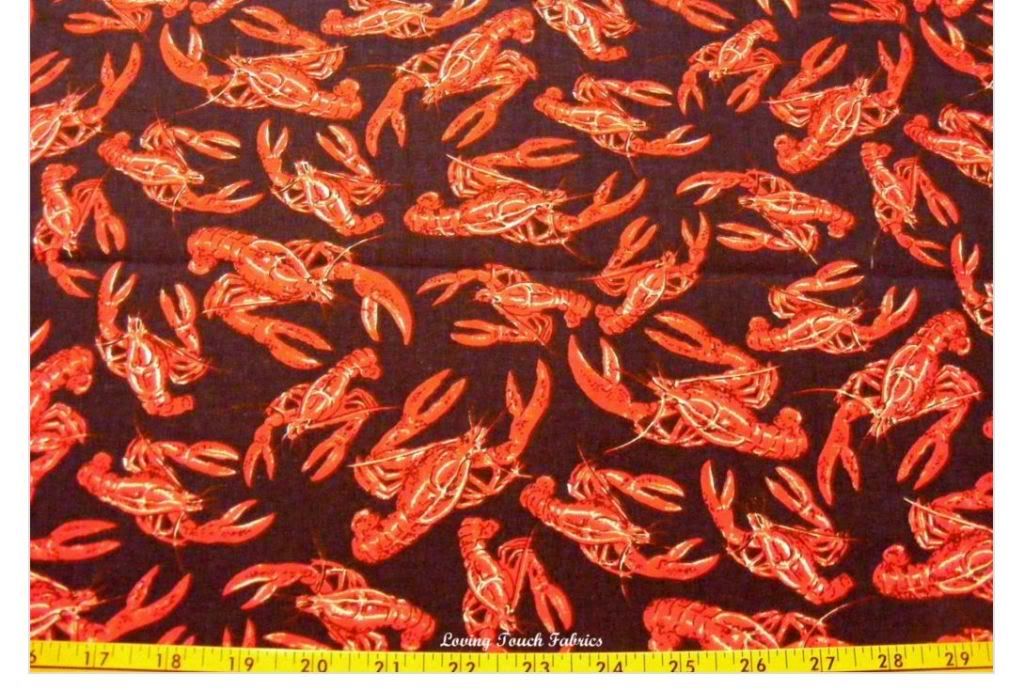

I got the material at Joannes:

Cheetah:

Dachshunds: