Error

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

skidesmond

- Posts: 2337

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

I bet that scared ya!

My air compressor hose is rated at 300psi max and it's nothing special. I use a pancake style compressor. You must of had a nick or weak spot in the hose, they shouldn't blow like that.

Why do I think we're being punked? Well, you're not listening to the people who have the experience and who have already gone down this road. Defies common sense.... and logic. You got me scratch my head.

Yes, DBS said to go the extra 20%. That's great advice and you should do that. But you still need to make it stronger as suggested by everyone.

Just my 2cents.

My air compressor hose is rated at 300psi max and it's nothing special. I use a pancake style compressor. You must of had a nick or weak spot in the hose, they shouldn't blow like that.

Why do I think we're being punked? Well, you're not listening to the people who have the experience and who have already gone down this road. Defies common sense.... and logic. You got me scratch my head.

Yes, DBS said to go the extra 20%. That's great advice and you should do that. But you still need to make it stronger as suggested by everyone.

Just my 2cents.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

got you scratching your head? i guess thats good?

when inflating it the first time i set up a ply wood wall for me to stand behind.

i was waiting for it to explode or " taco " as montucky said. but none of which hapened.

my 2 cents are putting on those cross section supports is alot of work. and im completely unhappy having to do that. but meh. as long as it doesnt explode.

after running all my strength tests i knew that the press was going to be fine.

every body was scared for the angle iron. but the crosection held it in from twisting. i just had a good guess with it.

but i dont think that the press would work with out those flatbars.

when inflating it the first time i set up a ply wood wall for me to stand behind.

i was waiting for it to explode or " taco " as montucky said. but none of which hapened.

my 2 cents are putting on those cross section supports is alot of work. and im completely unhappy having to do that. but meh. as long as it doesnt explode.

after running all my strength tests i knew that the press was going to be fine.

every body was scared for the angle iron. but the crosection held it in from twisting. i just had a good guess with it.

but i dont think that the press would work with out those flatbars.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

rectangular tube? you mean flat bar? edit: <------ joke. i dot want any more queries.doughboyshredder wrote:one more point.

Spring steel is a waste of money in this application.

What you need is the same rectangular tube in at least 1/4" wall, IMO.

will do tho. but only when theese that i have right now are completely garbage. but with the pipe inside, doesnt even bend any more

If you think puting three supports on, which I imagine involves tightening 3 nuts, is a lot of work then you might be a little put out by all the other work that goes into a pair of skis!my 2 cents are putting on those cross section supports is alot of work. and im completely unhappy having to do that.

puting those supports on each time would take only a few minutes and is pretty necessary for your press to work.

COsurfer uses similar supports on his press and I think he has worked out that you can loosen the nuts and slide them to the ends while you load the press, then slide them out and tighten them up before you crank on the air.

http://www.skibuilders.com/phpBB2/viewt ... 72&start=0

http://www.skibuilders.com/phpBB2/viewt ... c&start=15

Don't wait up, I'm off to kill Summer....

20% extra on 40 psi would have been 48% - the welds, bolts and steel you are using don't care if you're trying to prove a point or if you're not paying attention to the gauge you are using. They will kill you when you take them beyond the tolerance you have YET TO CALCULATE. The worrying thing ... it does not have to be today, they will wait and slowly fatigue, then hit you at a time of their choosing. Probably on the day you chose not to tighten those few bolts and you are showing your friends just how everything works. That's how these things usually happen.

I hope you chose to always inflate your press from behind a plywood board and then close off your garage. I doubt you will because your mind is set on proving what you are told by others is not the only path - your journal is full of this. Unfortunately, steel is steel, pressure is pressure, fatigue will happen and you are made of fresh.

I hope to be proven so wrong to write this ... I'm not here to monitor what you are doing, but I don't want others to copy the attitude you have taken to the advice you have been given.

I hope you chose to always inflate your press from behind a plywood board and then close off your garage. I doubt you will because your mind is set on proving what you are told by others is not the only path - your journal is full of this. Unfortunately, steel is steel, pressure is pressure, fatigue will happen and you are made of fresh.

I hope to be proven so wrong to write this ... I'm not here to monitor what you are doing, but I don't want others to copy the attitude you have taken to the advice you have been given.

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

No, sorry. You did not have a good guess. Your angle iron isn't doing shit (which is a good thing). The cross section isn't holding the angle iron from twisting because the angle iron isn't taking any load at all.a.badner wrote: every body was scared for the angle iron. but the crosection held it in from twisting. i just had a good guess with it.

You could honestly ditch the ENTIRE frame, and use just the cross bars and threaded rod, and you'd have the exact same press... Glad to see you're using 5/8" rod though.

You'll probably do ok with what you have (but I still think it's unsafe), you just built a bunch of stuff for no reason (the whole top part of your frame)

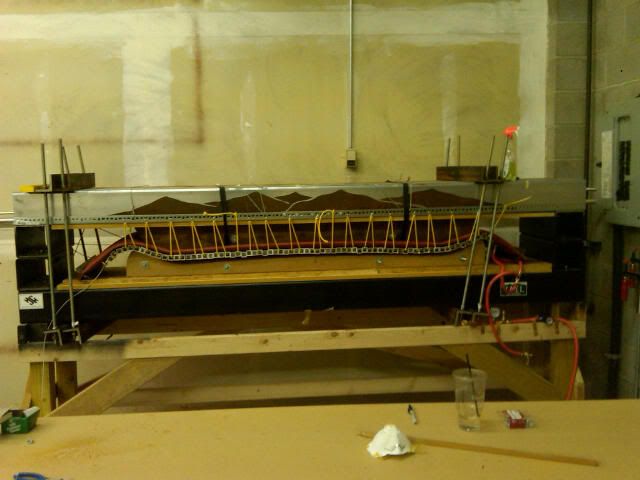

This is not cool:

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

And yes, putting cross bars on is a total pain in the ass. You've got epoxy curing, you've rushed the layup, now you've got to quickly thread those rods on there. It sucks, but a lot of people do it  That's why I-beam presses are so nice, or presses with pinned supports (like ours).

That's why I-beam presses are so nice, or presses with pinned supports (like ours).

Stick with low pressure (20-30psi?) and press a few skis. You'll want to build another press in the future, it will happen. But now you've got some lessons-learned behind you that will help you build something more substantial.

Stick with low pressure (20-30psi?) and press a few skis. You'll want to build another press in the future, it will happen. But now you've got some lessons-learned behind you that will help you build something more substantial.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

hey,

never sais it wasnt going to be ghetto.

im fifteen, and payed for this press completely out of my own pocket.

i ended up spending around $1000, but that is including tools.

if any body is looking to make an incredibly cheap pneumatic press that works. i guess you can follow this. but not recomended.

and obviously i will make more presses in the future. better quality and building. im just extremely happy that this one worked.

never sais it wasnt going to be ghetto.

im fifteen, and payed for this press completely out of my own pocket.

i ended up spending around $1000, but that is including tools.

if any body is looking to make an incredibly cheap pneumatic press that works. i guess you can follow this. but not recomended.

and obviously i will make more presses in the future. better quality and building. im just extremely happy that this one worked.

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA