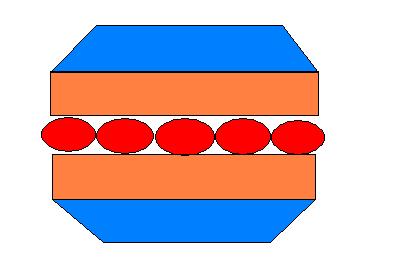

Here is the overall press:

The materials haven't been picked out quite yet but he has some ideas of what they might be. They are as follows:

Blue: massive wood like fir or maybe MDF

Red: MDF with plywood on top, maybe (I think think MDF is the best)

Orange: wood or MDF

Yellow: MDF

Top mold might not be made totally from MDF he says.

His plans are to make it a double ski press that is roughly 15 inches wide (40cm). I am not sure if this is a good idea but from the look of his design I think it might work due to the very thick and well rounded over blue sections on the top and bottom. Making the blue parts separate from the bottom camber mold and the top mold will make the press very strong. I do think this press with be very heavy and a bear to slip the cloth over the entire mold pieces. I know from experience it is tough to load a double ski press. All of the layers drawn above add up in weight as you probably can imagine.

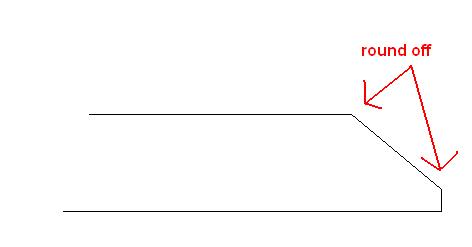

I think his drawing is very slick. I don't personally know how I would make the huge round over on the blue parts. I don't think my 1/4" roundover bit will work. Any ideas? It is very important to round over all the edges that will be touching the fabric. DO NOT have any sharp points or sharp edges. This is what ultimately ripped our first duck cloth bags.

Otherwise, if he can build this press as he has drawn it on the computer it will be very nice. Notice how the top mold slids on the dovetail rails. Also the tip and tail pieces on the bottom have similar ways of sliding while remaining in the right spot.

I think the key to building a ski press that utilizes fabric instead of steel is to make the bottom and top molds very thick and beefy. I would also say to make them the same length as this design shows. This will make it much easier to load. Make the top and bottom molds at least 3 inches thick.

He was very excited to hear MontuckyMadman can provide the cordura fabric as it is hard to find in his area.

For ski presses that use fabric I would not inflate the airbags to much over 40-45psi right now. I think the cordura will actually hold to much greater pressures than most peoples top of bottom molds will be able to stand. I think Montucky broke his top mold lengthwise at around 50psi. The cloth was fine.

I am still not convinced you need to press much higher than 40psi. Hell, vacuum bagging is only around 14psi (without any sort of crazy autoclave thingy I don't fully understand so I won't try and start an argument with anyone). I am just trying to make a point that many folks here on this site have made some great looking skis with a vacuum bag with almost 2.5 times less pressure.

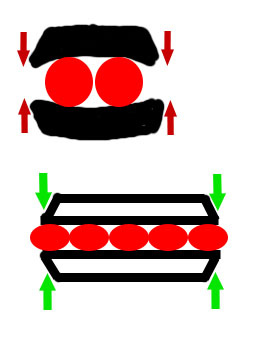

Some other pictures of cloth ski presses: Our old dual ski press before we chopped it in half like a snowboard into a pair of skis and before the duck cloth ripped:

Our ski press now as a single ski press with the new and improved cordura fabric:

Plywood's press from attila:

One of Plywood's first cloth frames I believe:

Plywood, if you want me to remove those two photos just let me know.