Page 1 of 3

update on press progress

Posted: Sun Aug 03, 2008 9:07 pm

by doughboyshredder

First off, I can't believe how much work has gone into this, and how much more there is to do.

Only a couple months until snow starts maybe falling in the higher elevations, so I gotta get cooking.

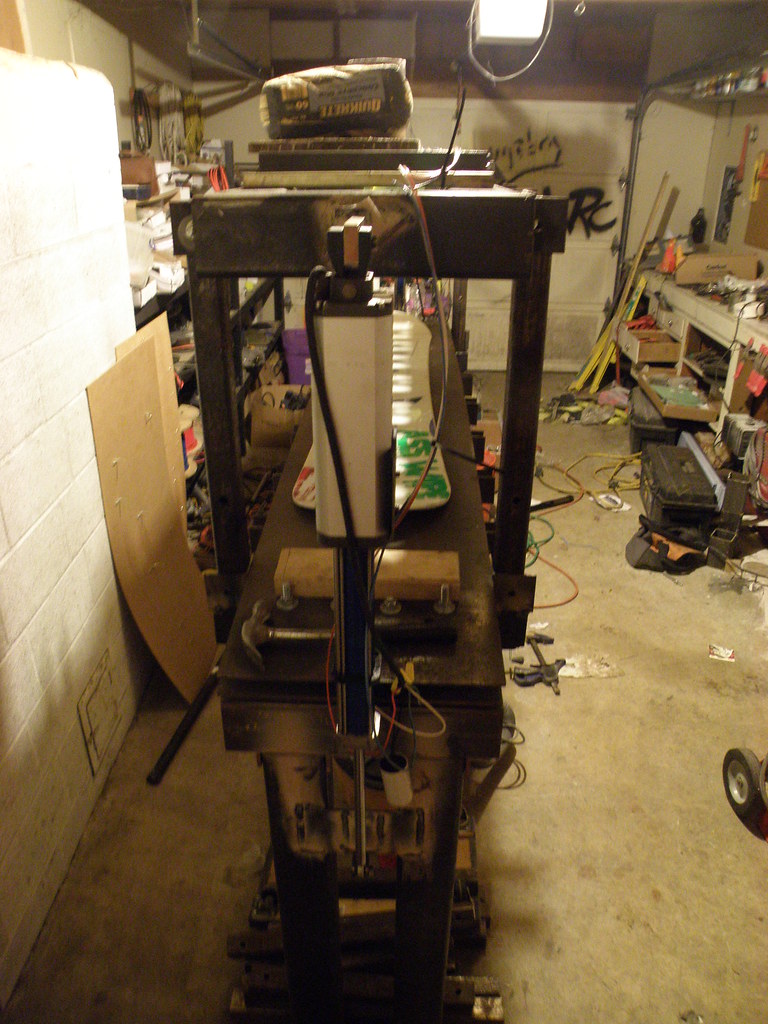

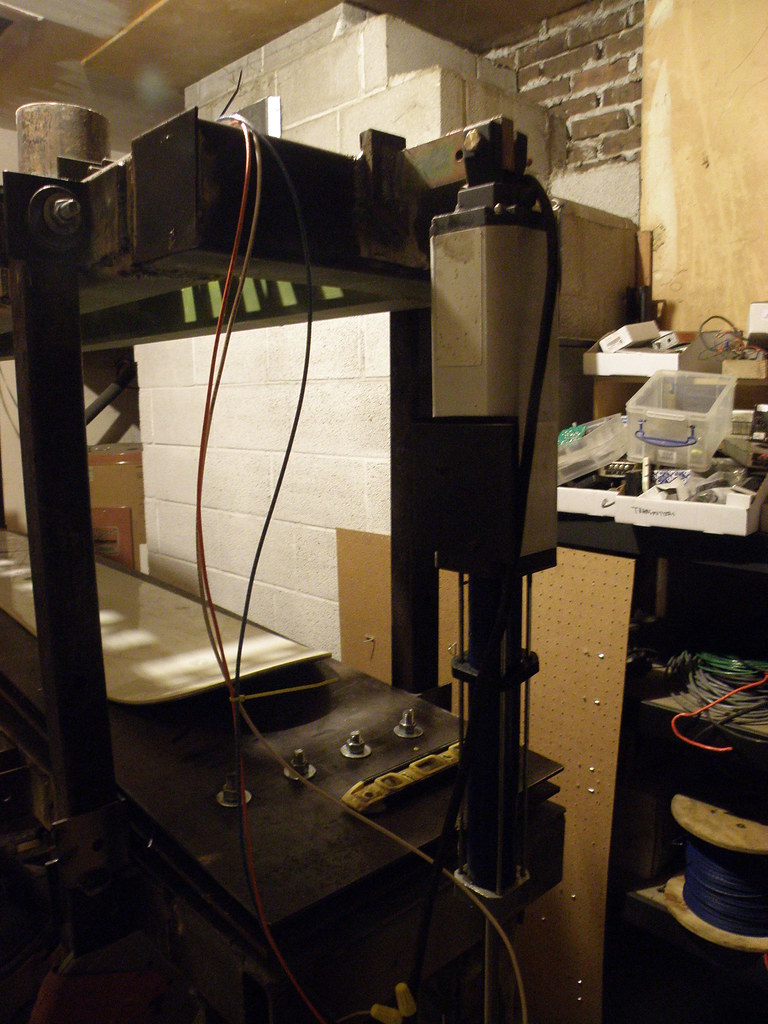

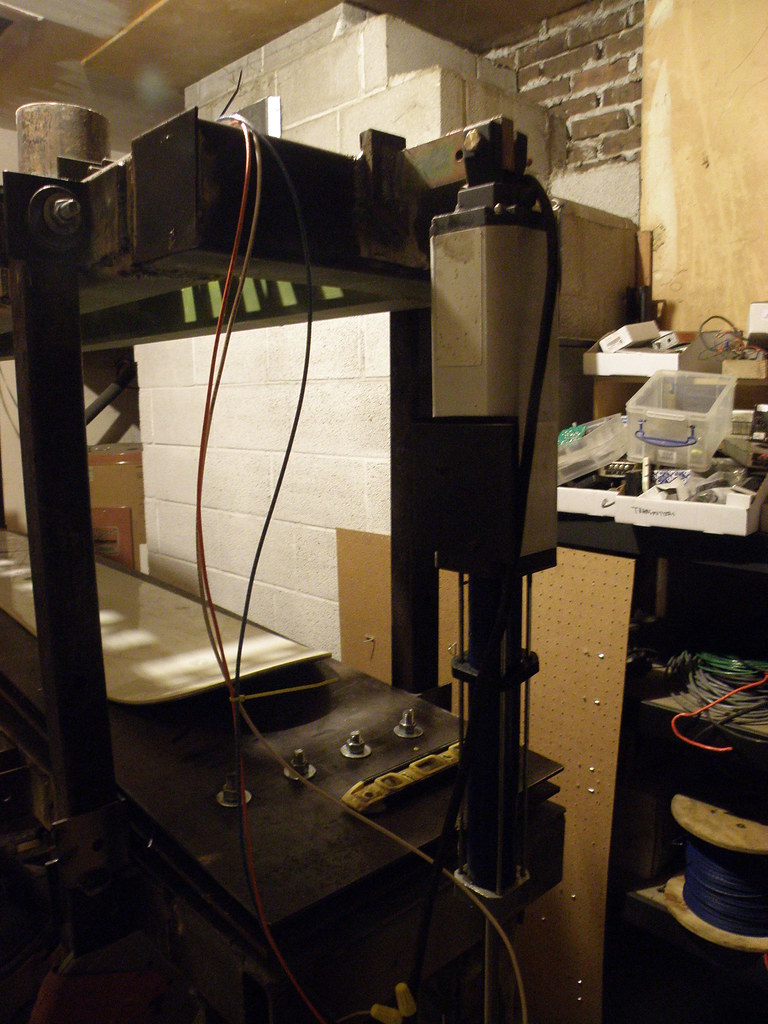

General idea is to have a hydraulically controlled pneumatic press with fully adjustable top and bottom molds.

I can't even remember how much time I have into this, but it's over 200 hours of cutting grinding and welding. So many cuts.

The whole thing is 1/4" thick steel. Nothing is light.

I hope to be able to press at about 80 PSI

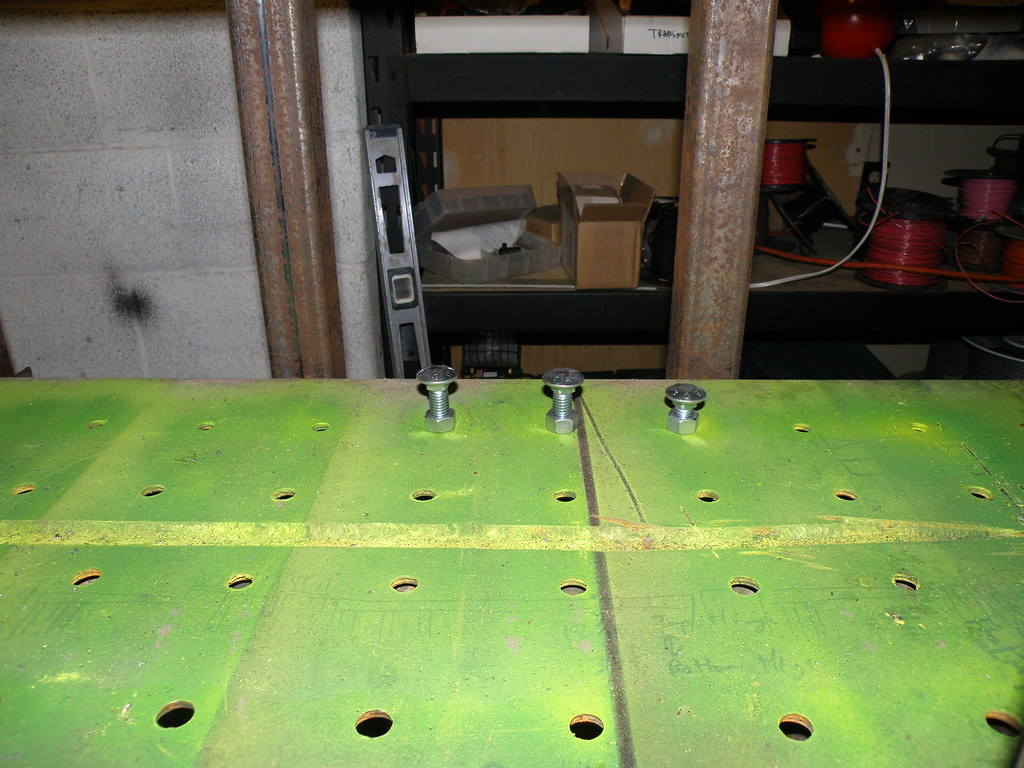

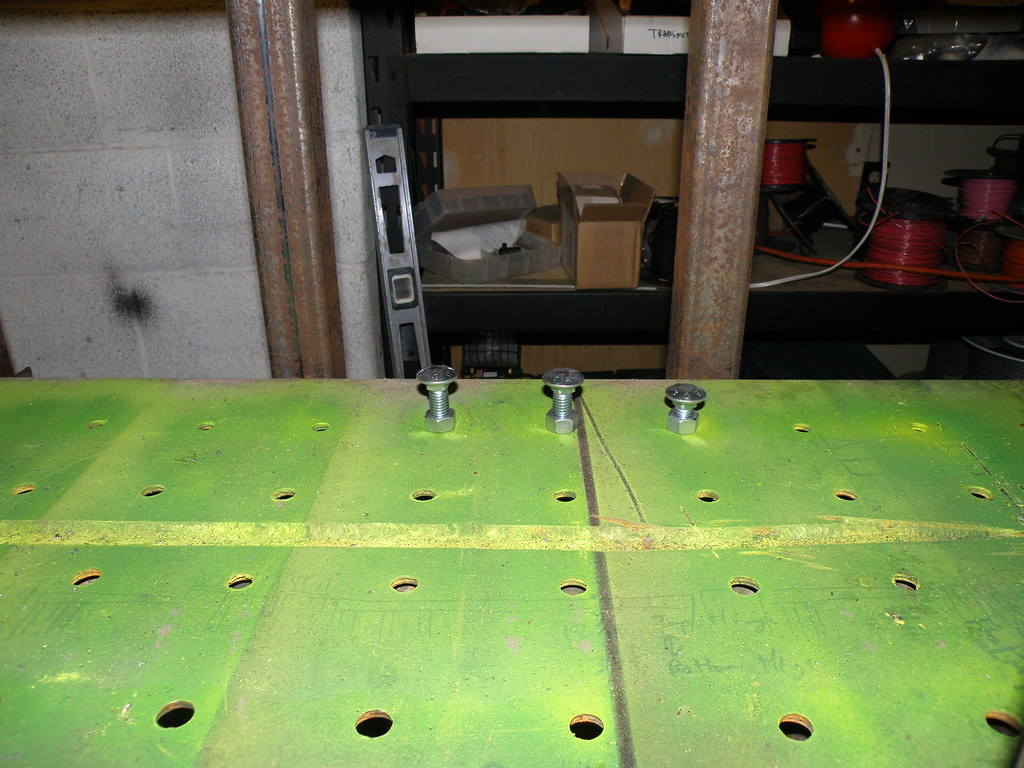

bottom plate is 1/4" thick and sits on top of the adjustment bolts. The 1" x 1/2" cat track pieces sit between this plate and another 1/4" thick bottom plate.

These same cat track pieces will be used for the upper cattrack. The vertical section is 1" tall to fight deflection.

Posted: Mon Aug 04, 2008 4:44 am

by Grizzly Adams

Damn! Looks like a lot of time and effort, but you are certainly coming along. Nice work!

Posted: Thu Oct 02, 2008 12:41 am

by doughboyshredder

mods, maybe move this thread...........sorry wasn't paying attention when I posted it.

I have made a lot of progress. I expect to be able to build something within the month.

I still need to rebuild and mount the hydraulic arms, build the interchangeable top block assembly, get heating blankets, and seal my airhoses, and, and , and, the list goes on.

Here are some more pics.

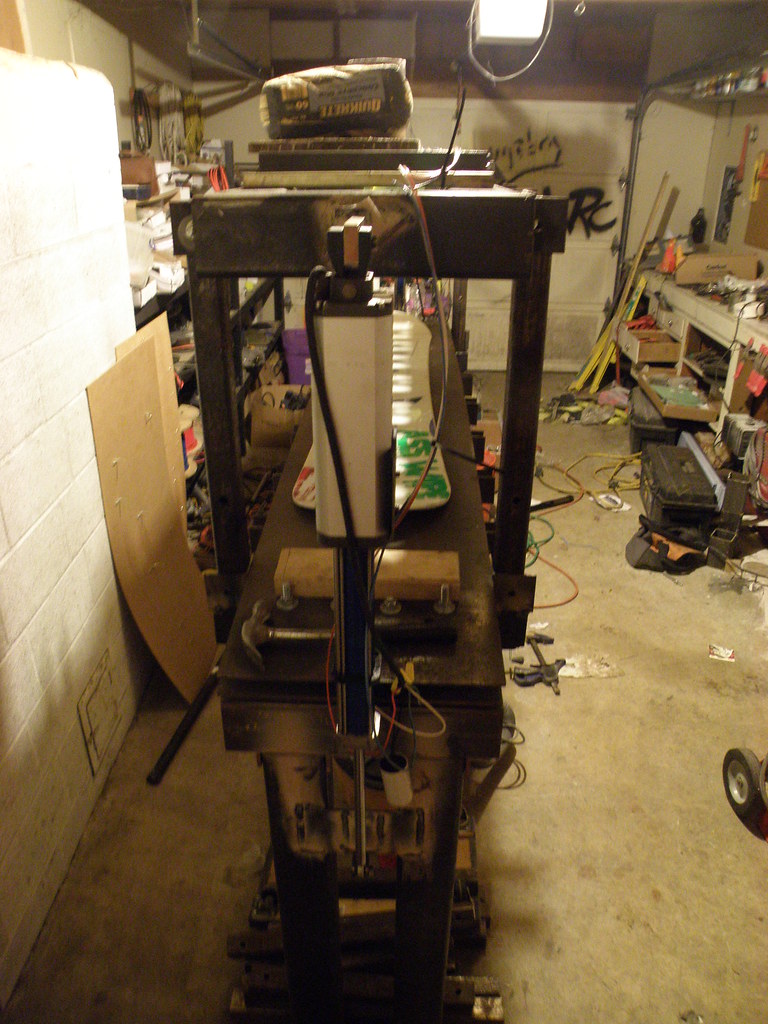

that's a 193 wide in the cavity. I set the press up so I can build a 220+ monster.

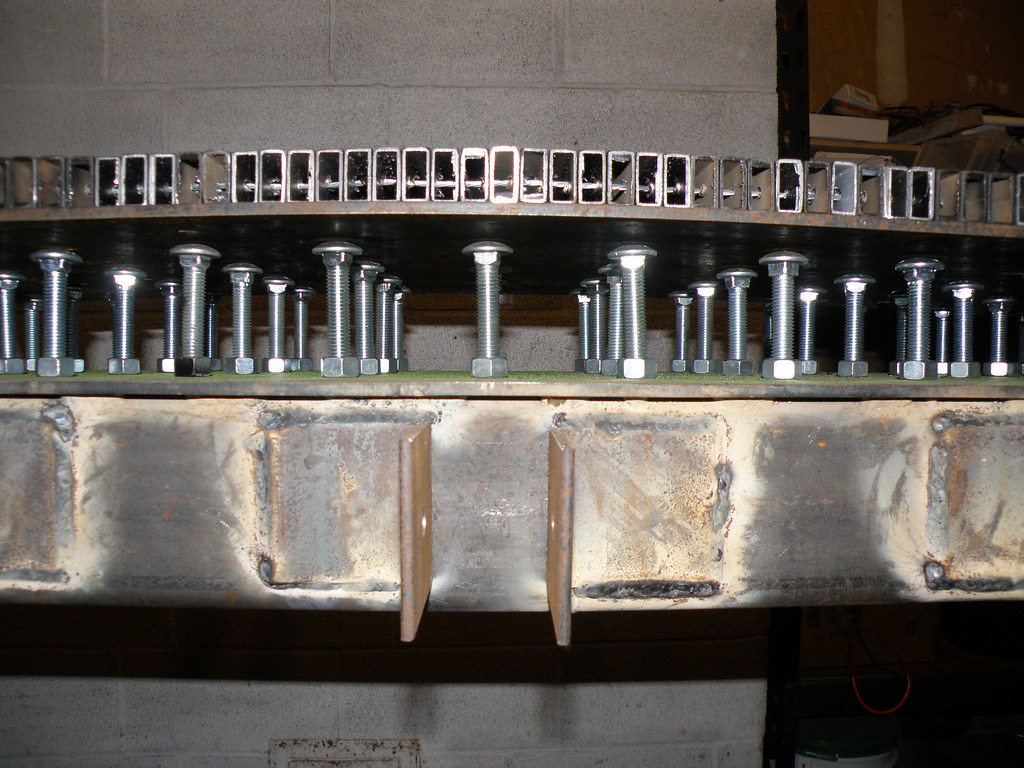

hydraulic rams

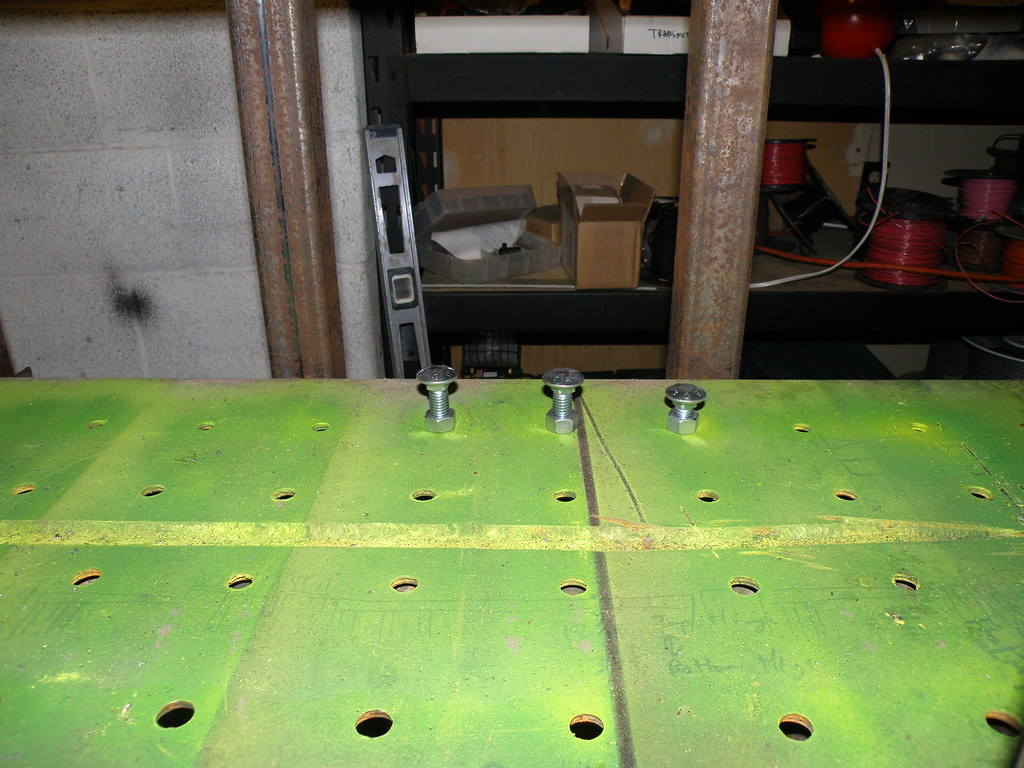

getting all 108 carriage bolts adjusted to the correct height = pain in the ass

carriage bolts, 1/4" plate, 1"x1/2" steel bar placed vertically, 1/4" steel plate. Think steel honeycomb to eliminate deflection of the adjustable camber plate.

same steel bar will be the upper cat track.

So stoked. 2 months to snowtime........

Re: update on press progress

Posted: Thu Oct 02, 2008 4:06 am

by krp8128

doughboyshredder wrote:

I hope to be able to press at about 80 PSI

It looks pretty good, but holy sh!t do those carriage bolts scare me! Please tell me they were just for the mock-up.

Posted: Thu Oct 02, 2008 7:23 am

by doughboyshredder

The carriage bolts should be good.

I figure a total of 90,000 pounds of pressure. 108 carriage bolts. Less than 1,000 pounds of pressure per carriage bolt.

I looked up the strength of the carriage bolts a while ago, and determined that the shear strength is rated at I think I remember 8,000 lbs. Obviously this is not a complete shear situation, and most of the pressure will actually be exerted downward.

At one point I was going to use hardened carriage bolts, but the difference in strength was not significantly higher.

I still am also a little bit worried, just because it doesn't look right. I guess we'll see.

I plan on slowly ramping pressure up and then I guess we'll see if they bend.

What's your concern? Do you have any suggestions?

Posted: Tue Nov 04, 2008 8:41 am

by doughboyshredder

Posted: Thu Nov 06, 2008 10:09 pm

by rockaukum

I'm interested in the hydraulic ram system for raising the top of the mold. Give a bit more info when you get a chance...

Thanks,

ra

Posted: Fri Nov 07, 2008 3:50 pm

by doughboyshredder

Ra-

The hydraulic pistons I have are gate operators that I removed and rebuilt. They generate about 2,000lbs of force at the end of a 1/2" shaft. I think they might not be strong enough to actually lift the entire upper block assembly. Because of this, I am now thinking about mounting them on the front of the press and using them to pivot the front open. Kind of like a clam shell. I think this will also make aligning the brace holes easier.

I wanted to be able to move the upper block out of the way so that I could load my casette in to the press without having to have the tips and tails pre bent.

Posted: Fri Nov 07, 2008 4:07 pm

by rockaukum

I am currently re-doing my press and was hoping to do the same thing. I wanted to raise up the upper portion of my press so the the lay-up would be nice and easy to insert and then lower the top portion back down, pin it into place and press away. However I' m pretty cheap and don't want to spring the $200 or so for the air assisted jacks. Might be looking into just using bottle jacks or even using a cable winch like used for pullling boats onto the trailer. No too sure yet but still looking into other ideas.

Thanks for the reply and I'll be watching for your solution.

ra

Posted: Mon Nov 10, 2008 8:10 pm

by doughboyshredder

So stoked! The hydraulics are mounted and functioning. I have a few minor guiding issues that I have to resolve, but the rams are able to raise the top block as long as it does not bind at all.

Posted: Thu Nov 13, 2008 2:06 pm

by hugocacola

hey dough

i see your good work, but i have a bad news to give you... well not important but the cat trck you bild with 2 steel sheet of 10mm each is a waist o money, 1 steel sheet for your system is enought,, i am tolding you because i have a camber mold like your...

Posted: Fri Nov 21, 2008 6:40 pm

by doughboyshredder

thanks hugo for the compliment.

I looked at your camber mold. Isn't your plate thicker? Your adjustment bolts seem to be attached to a bar also?

I got the cattrack steel for free so there was no expense involved there. I was pretty sure that my adjustment bolts would push dimples right through the bottom plate and in to the snowboard if I didn't do that sandwich. Besides, the stronger the better right?

Posted: Fri Nov 21, 2008 9:25 pm

by knightsofnii

whenever you think you've taken something too far, just go look at pics of burton presses,

. Looks awesome!

Posted: Fri Dec 05, 2008 9:02 pm

by doughboyshredder

up

and down

It works! Smoothly!

I even loaded a 60 lb bag of crete and a 80 lb block of steel on top, doesn't even faze the hydraulics.

Now on to the tip and tail blocks and the top blocks.

Posted: Fri Dec 05, 2008 10:15 pm

by rockaukum

Why not turn the rams over and make a true hydraulic press?

keep the good news and pics coming.

ra