Only a couple months until snow starts maybe falling in the higher elevations, so I gotta get cooking.

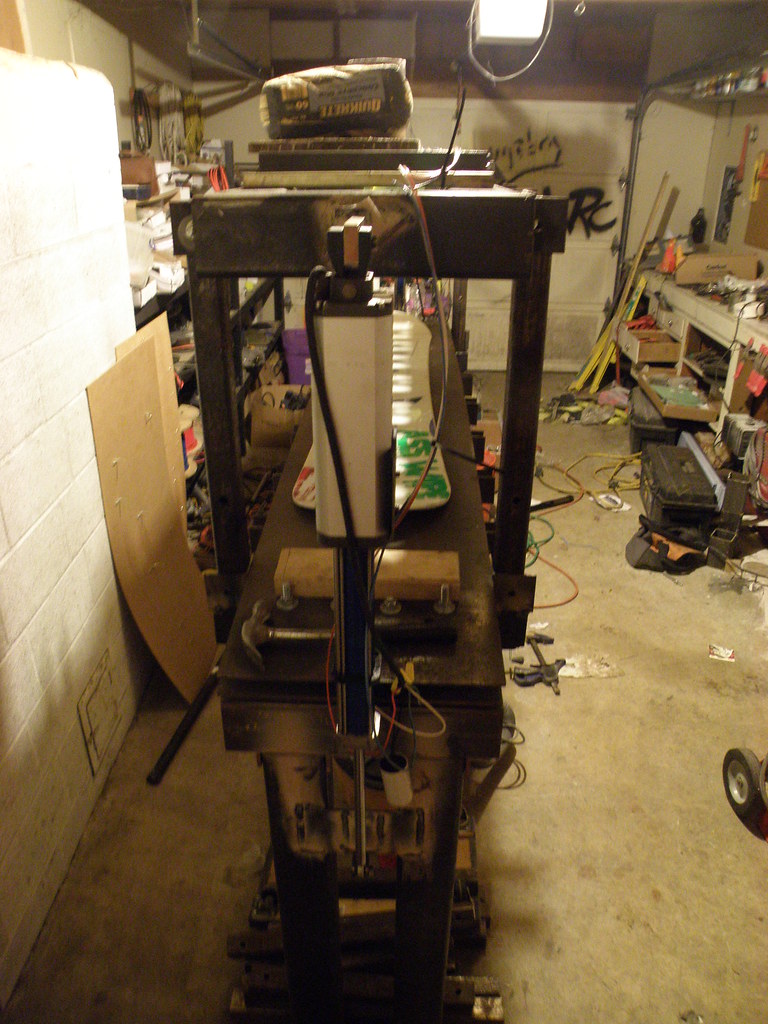

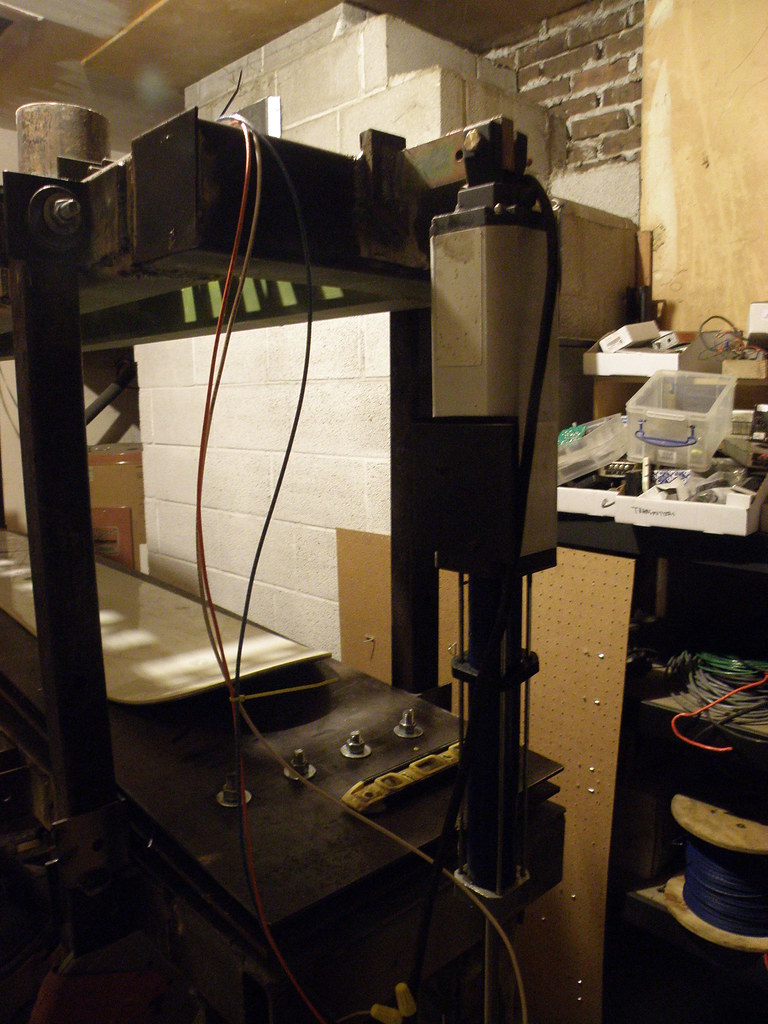

General idea is to have a hydraulically controlled pneumatic press with fully adjustable top and bottom molds.

I can't even remember how much time I have into this, but it's over 200 hours of cutting grinding and welding. So many cuts.

The whole thing is 1/4" thick steel. Nothing is light.

I hope to be able to press at about 80 PSI

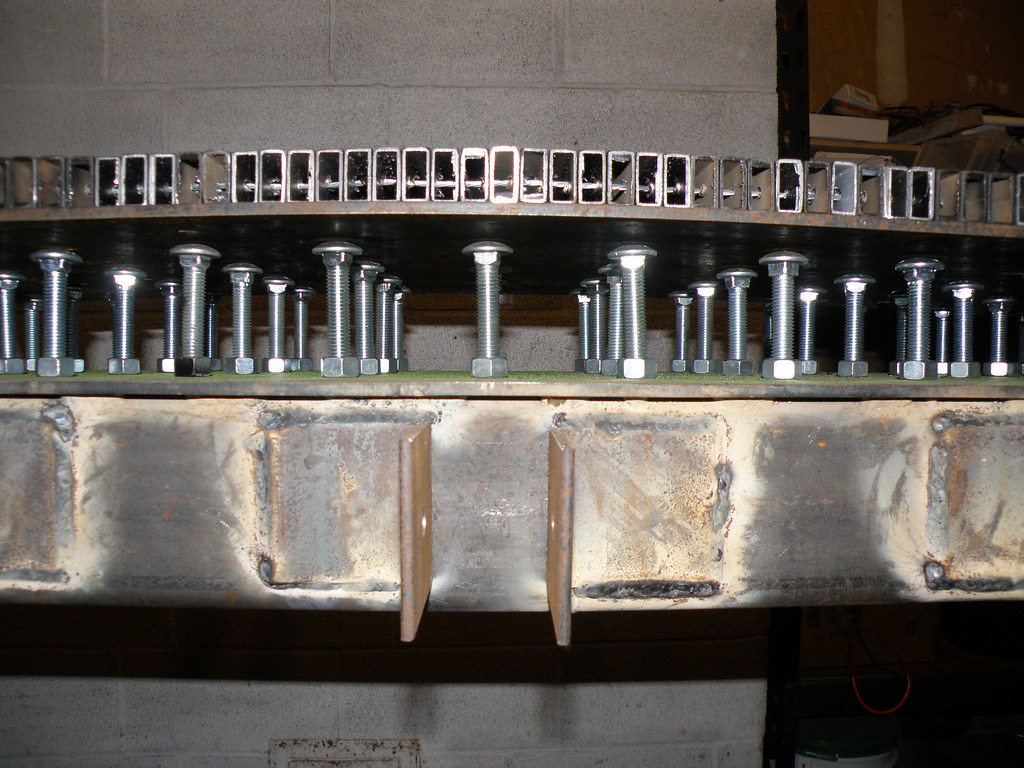

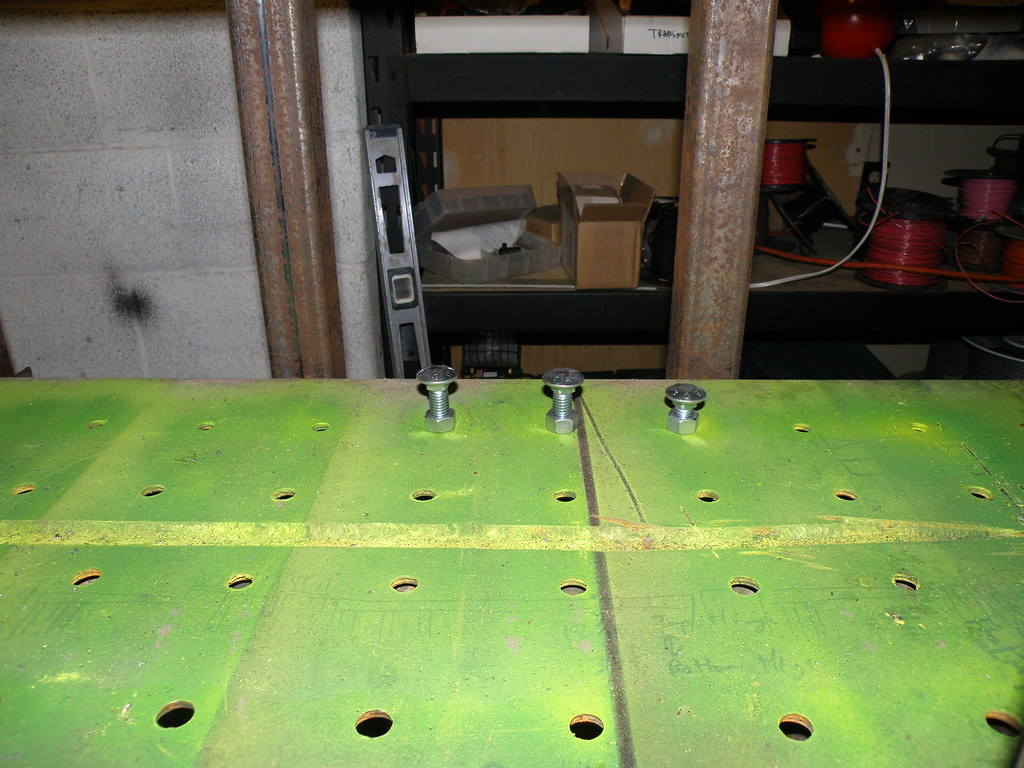

bottom plate is 1/4" thick and sits on top of the adjustment bolts. The 1" x 1/2" cat track pieces sit between this plate and another 1/4" thick bottom plate.

These same cat track pieces will be used for the upper cattrack. The vertical section is 1" tall to fight deflection.