New Ski Making Workshop - Complete with Press et all!

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

I don't really want to get into the thick of an engineering debate, but I remember that, a year or so ago, someone posted a pic of their I-beam press (designed as in the above pics) in which an I-beam flange did, in fact, tear off of one of the short end pieces when the press was pressurized. Looked quite gnarly. I looked around for that thread/pic, but couldn't find it. Maybe someone else remembers it and knows where to find it. I share the opinion that the flanges of an I-beam are not designed to be loaded in tension in a perpendicular direction away from the longitudinal axis of the beam. If, in the above design, one were to use very long bolts and bolt through the entire I-beam sandwich (instead of just bolting the individual flanges), the beams would then be loaded correctly.

Again I say, ditch the I-beams and get with something lighter and more soundly engineered... especially if you have such big aspirations for becoming a major player in the ski industry.

Cheers,

G-man

Again I say, ditch the I-beams and get with something lighter and more soundly engineered... especially if you have such big aspirations for becoming a major player in the ski industry.

Cheers,

G-man

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

cheers

G-Man I think i owe you a beer.

Thanks. Now if we can get doughboy to agree

Thanks. Now if we can get doughboy to agree

I know of those Ibeams. I now have those very same Ibeams. There was a "seperation" on the beam. It "pealed" back at one end about 10". What must be understood about the pealing of those / these Ibeams in particular is that they were welded Ibeams. The original Ibeam in question did not have a continious weld to the end (where it was bolted together. This is where the pealing occured. I have since pressed the flange back into position and welded it together. I have since pressured it, and pressed one set of skis with out any problems. I questioned this post earlier (I'll bite...) and now understand what you guys were talking about, the flange at the ends are in question. Not the beams that run the length (?).

Now a question to continue the disscussion. willl recreational ski building (about 5 per year) at a pressure up to 40 psi present any forseen problems?

Thanks for the lessons....

rockaukum

Now a question to continue the disscussion. willl recreational ski building (about 5 per year) at a pressure up to 40 psi present any forseen problems?

Thanks for the lessons....

rockaukum

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

yes

The beam is by far strong enough, the problem is the flange in my eyes. if you were to band the two flanges together with a piece of 1/4" bar or something it would probably be plenty strong. The beam will catastrophically fail at a certain psi, not with repetition. (as you would see the fatigue) Take it form someone who blew up a press the first time it was pressurized (me) its not fun, It almost broke my Brothers leg and put a huge hole in our press room wall. Ours was not due to welds but do to a bad centering job of the cassettes and hose. BE CAREFUL! Have Fun.

I understand what you guys are saying about using the I-beams as connectors, but couldn't this problem be mitigate somewhat by using steel tubing instead of a piece of I-beam?

That is what I did with my press:

I don't know much about all of this stuff, but this seems like a stronger configuration to me. Can you guys who actually know about this comment?

I can say that I press my skis at 70psi. It is only a single ski press (sadly) but I have had no issues at all with the 20+ skis I have press so far. I am making a mad dash to finish skis before I move to Portland in August, so need to finish about another 30+ pairs, so the press will certainly get tested durability wise. Last week was pressing 6 skis a day and again, really no issues.

It is interesting for sure to hear you guys talk about lighter, more complicated presses, but for some of the less engineering oriented builders, the best way to deal with the huge amounts of pressure being exerted on the ski press is to go with massive weight and simple design. Is it the best? No. But it does work and is easy to build.

I know that my next likely press (hopefully) will be a double wide, double bay press. Plans had been to just make it pretty big, but it is appealing to incorporate some sort of cross member system as long as it does not imped on the ability to put skis in the press and pull them out very quickly. And it pretty easy to build. I am pretty sure at this point, with all the steel cut and the right tools to get the heavy piece in position, it would not take more than a week or two to build a huge double bay, double wide press. My press was way too complicated due to my desire to lift it off the ground. Because of that it too a long long time to drill and have it all line up.

That is what I did with my press:

I don't know much about all of this stuff, but this seems like a stronger configuration to me. Can you guys who actually know about this comment?

I can say that I press my skis at 70psi. It is only a single ski press (sadly) but I have had no issues at all with the 20+ skis I have press so far. I am making a mad dash to finish skis before I move to Portland in August, so need to finish about another 30+ pairs, so the press will certainly get tested durability wise. Last week was pressing 6 skis a day and again, really no issues.

It is interesting for sure to hear you guys talk about lighter, more complicated presses, but for some of the less engineering oriented builders, the best way to deal with the huge amounts of pressure being exerted on the ski press is to go with massive weight and simple design. Is it the best? No. But it does work and is easy to build.

I know that my next likely press (hopefully) will be a double wide, double bay press. Plans had been to just make it pretty big, but it is appealing to incorporate some sort of cross member system as long as it does not imped on the ability to put skis in the press and pull them out very quickly. And it pretty easy to build. I am pretty sure at this point, with all the steel cut and the right tools to get the heavy piece in position, it would not take more than a week or two to build a huge double bay, double wide press. My press was way too complicated due to my desire to lift it off the ground. Because of that it too a long long time to drill and have it all line up.

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

Only structural i-beams should be used, and there are no welds on a structural i-beam. The tore I-beam pic was not a structural I-beam and the welding was not continuous.

The strength of an I-Beam is in fact caused by the flange and the webbing on the flange.

I never said I was a civil engineer. I do have 15 plus years of experiencing building with steel, and am a general contractor, so I am not talking out of my ass.

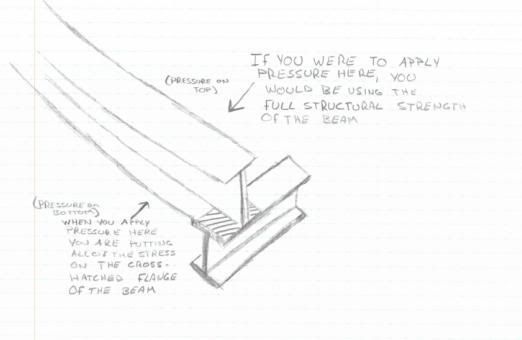

Heliski, you stated that the beams were in the wrong orientation. Care to expand on that.

The strength of an I-Beam is in fact caused by the flange and the webbing on the flange.

I never said I was a civil engineer. I do have 15 plus years of experiencing building with steel, and am a general contractor, so I am not talking out of my ass.

Heliski, you stated that the beams were in the wrong orientation. Care to expand on that.

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

I remember the pic of that I-beam that tore apart. It was the welds that tore, and a true I-beam should have a continuous cross section (without welds).

Im not a licensed engineer but I graduated Mech-E and work in a Structural office (EIT / Drafter). BTW - to whoever said you should get a Mech-E to engineer the press - structural engineers, who design bridges and structures to support static loads, usually graduate with a degree in Civil Engineering, not Mechanical Engineering.

The end of the beam is still weak if only the insde flange is bolted , to strengthen it you should weld plates on the ends of the beams, both the longitudinal beams and the short spacer beams. You can, and should also strengthen the beams with web stiffeners (plates welded on the other side of the bolts).

Another option would be to run continuous all-thread through the spacer beams and through both flanges of the cross beams, and then bolt it together at the far flanges. This will cause the flanges to be loaded in compression instead of tension.

Iggy - Tube Steel would be good for sides (Longitudinal tension / compression) but I beams have a much higher second moment of inertia value with respect to cross sectional area than tube steel, and are better for the long beams that are resisting bending.

Cambilla - You have a great start. Good luck with everything, one other thing you may want to check is the deflection of such a long slender beam. Im not sure how long your press is, but if you only need a 7'-6" opening, dont make it 9'-0" long. It is okay with the upper beam, but the lower beam designates how "Flat" the press will be. If it deflecs and bends alot it will negate, or flaten out any camber you have in the mold you cut.

Although, through different heat ramp rates you can add camber to a ski in any mold.

Good Luck

Im not a licensed engineer but I graduated Mech-E and work in a Structural office (EIT / Drafter). BTW - to whoever said you should get a Mech-E to engineer the press - structural engineers, who design bridges and structures to support static loads, usually graduate with a degree in Civil Engineering, not Mechanical Engineering.

The end of the beam is still weak if only the insde flange is bolted , to strengthen it you should weld plates on the ends of the beams, both the longitudinal beams and the short spacer beams. You can, and should also strengthen the beams with web stiffeners (plates welded on the other side of the bolts).

Another option would be to run continuous all-thread through the spacer beams and through both flanges of the cross beams, and then bolt it together at the far flanges. This will cause the flanges to be loaded in compression instead of tension.

Iggy - Tube Steel would be good for sides (Longitudinal tension / compression) but I beams have a much higher second moment of inertia value with respect to cross sectional area than tube steel, and are better for the long beams that are resisting bending.

Cambilla - You have a great start. Good luck with everything, one other thing you may want to check is the deflection of such a long slender beam. Im not sure how long your press is, but if you only need a 7'-6" opening, dont make it 9'-0" long. It is okay with the upper beam, but the lower beam designates how "Flat" the press will be. If it deflecs and bends alot it will negate, or flaten out any camber you have in the mold you cut.

Although, through different heat ramp rates you can add camber to a ski in any mold.

Good Luck

Brian

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

And you said their beams were oriented incorrectly. Again, I ask you how? You said you were going to post a pic. I would like to see that.heliski989 wrote:post was pointed at cambillaskis.co.uk

You made a strongly worded post that somebody was doing something wrong. I am only asking you to further your thought on this subject. I am curious. I may be misunderstanding what your point is, and I would be curious to find out if that is the case.

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

i think it will be fine depending on the level of production he wants to do.

then just more bracing and nice solid molds.

one could always just build a giant cavity mold, and pour molten steel into it and let it cool, and make a MONO-COCK press frame .

.

in all reality, its tough to just whip up plans then head to your steel yard and say "yea i need this and this", opportunities present themselves then you have to plan accordingly to design your press.

i bought mine. a few thousand boards is proof enough that it's solid, but still i'm going to add more supports.

then just more bracing and nice solid molds.

one could always just build a giant cavity mold, and pour molten steel into it and let it cool, and make a MONO-COCK press frame

in all reality, its tough to just whip up plans then head to your steel yard and say "yea i need this and this", opportunities present themselves then you have to plan accordingly to design your press.

i bought mine. a few thousand boards is proof enough that it's solid, but still i'm going to add more supports.

Doug

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact:

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

what if you take the small pieces of ibeam and rotate them 90degrees so they are parallel to the long pieces?

you would most likely reduce the bending moment in the vertical center part of the section of the beam. Sorry i dont know what that part of the beam is called its been long time since I took strength of materials. But by rotating 90degrees you are most likely using more of the full strength of the beam.

I'm not gonna try it because my press beams are already set up to work the way they are with minimal deflection at 60psi (tested to 100psi+) but for anyone building or designing it's something to consider.

you would most likely reduce the bending moment in the vertical center part of the section of the beam. Sorry i dont know what that part of the beam is called its been long time since I took strength of materials. But by rotating 90degrees you are most likely using more of the full strength of the beam.

I'm not gonna try it because my press beams are already set up to work the way they are with minimal deflection at 60psi (tested to 100psi+) but for anyone building or designing it's something to consider.

Doug

-

heliski989

- Posts: 117

- Joined: Sat Jan 27, 2007 8:29 pm

- Location: Denver, CO

- Contact: