198cm 110 under foot, 30m radius

Posted: Thu Apr 10, 2008 6:53 pm

I havent posted in a while because Ive been super busy w/ work school and trying to build skis. but here are a couple of new pairs from the past couple of months

http://www.facebook.com/album.php?aid=4 ... =602540836

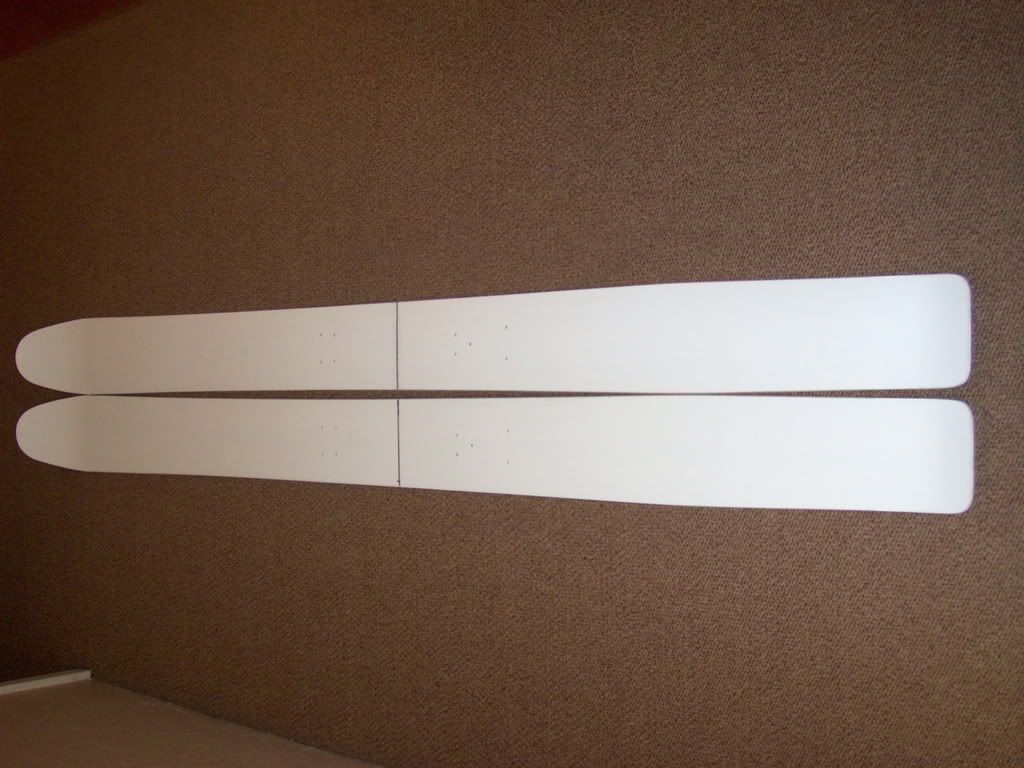

Here are the cut bases getting edged.

just before top sheet

198's in the press

a pair of 198's on (R), and 179.5's on (L)

Past present and future

tip spacer and wood (bamboo) sidewalls

view of tip

camber and sidewalls

in the line up

Specs on the 198's

Sidecut - 30m - 137-110-129

Running surface - 165

tip / tail running surface 90cm / 75cm

Mold, Adjustable flat mold w/ 21cm radius tip and tail molds

core

2.5-12.5-2.5 bamboo w/ uhmd tip and tail spacer

Ive been stopping the edges just before the tip starts to make a tight radius (as sseen in some pics) Ive been doing this so it is hopefully less likely to delam.

Pressing conditions

garage temp ~ 50 degrees

after I lay up the ski I slide it in the press, inflate the air bag to 70 psi, and let the ski sit at 100 degrees for +/- 15 minutes and then ramp the temp up to 180 with out stopping. In doing so, ive been getting about 3 mm of total camber (1.5 mm per ski) while pressing in a FLAT MOLD. Im assuming If I let the ski sit at a lower temp, like 90 or 85 degrees, for the 15 min period, it would have less added camber. (once ramped from 40 to 180 and got about 1 cm of rocker, friend did a very slow ramp and with about 3 or 4 increments and got about 1 cm of camber)

After letting the ski sit for 15 min at 100 I bring it to 180 and leave it there for 45 to 60 min.

The other pair of skis are 179.5's (180 I guess). Have the same basic construction.

sidecut

136-97-123 - 18m radius in the tip, 24m radius in the tail, w/ radius change under foot.

this ski came out stiff b/c of the core, and is great in hard-pack and carves well. Not sure how I feel about the dual radius sidecut.

core

3.5-13.5-3.5 bamboo w/ tip/tail spacer

http://www.facebook.com/album.php?aid=4 ... =602540836

Here are the cut bases getting edged.

just before top sheet

198's in the press

a pair of 198's on (R), and 179.5's on (L)

Past present and future

tip spacer and wood (bamboo) sidewalls

view of tip

camber and sidewalls

in the line up

Specs on the 198's

Sidecut - 30m - 137-110-129

Running surface - 165

tip / tail running surface 90cm / 75cm

Mold, Adjustable flat mold w/ 21cm radius tip and tail molds

core

2.5-12.5-2.5 bamboo w/ uhmd tip and tail spacer

Ive been stopping the edges just before the tip starts to make a tight radius (as sseen in some pics) Ive been doing this so it is hopefully less likely to delam.

Pressing conditions

garage temp ~ 50 degrees

after I lay up the ski I slide it in the press, inflate the air bag to 70 psi, and let the ski sit at 100 degrees for +/- 15 minutes and then ramp the temp up to 180 with out stopping. In doing so, ive been getting about 3 mm of total camber (1.5 mm per ski) while pressing in a FLAT MOLD. Im assuming If I let the ski sit at a lower temp, like 90 or 85 degrees, for the 15 min period, it would have less added camber. (once ramped from 40 to 180 and got about 1 cm of rocker, friend did a very slow ramp and with about 3 or 4 increments and got about 1 cm of camber)

After letting the ski sit for 15 min at 100 I bring it to 180 and leave it there for 45 to 60 min.

The other pair of skis are 179.5's (180 I guess). Have the same basic construction.

sidecut

136-97-123 - 18m radius in the tip, 24m radius in the tail, w/ radius change under foot.

this ski came out stiff b/c of the core, and is great in hard-pack and carves well. Not sure how I feel about the dual radius sidecut.

core

3.5-13.5-3.5 bamboo w/ tip/tail spacer