sammer's skis

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

OAC good to hear your making some progress. I'd like to hear more about your rubber once you get to try it.

Once I get kids off to school I'm heading down to the dungeon to try and make some progress as well.

My plan was to make my frame out of 1x4 maple thinking that should be heavy enough.

sam

Once I get kids off to school I'm heading down to the dungeon to try and make some progress as well.

My plan was to make my frame out of 1x4 maple thinking that should be heavy enough.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

Still too rainy to pull the MDF out of the shed.

Its been raining pretty much none stop for a week.

But still lots to do in the dungeon.

Built the base for the new press bench.

Built a new camber mold.

Used the tried and true profile jig.

Turned out pretty good. Although the early rise starts a little earlier than on the last few pairs.

I was planning on building it out of MDF but wasn't gonna make that much dust in the house.

So ended up using 2x6 I've had taking up space forever.

Gotta find a good home for the old kayak as that's where my new press has to go.

More as it progresses.

sam

Its been raining pretty much none stop for a week.

But still lots to do in the dungeon.

Built the base for the new press bench.

Built a new camber mold.

Used the tried and true profile jig.

Turned out pretty good. Although the early rise starts a little earlier than on the last few pairs.

I was planning on building it out of MDF but wasn't gonna make that much dust in the house.

So ended up using 2x6 I've had taking up space forever.

Gotta find a good home for the old kayak as that's where my new press has to go.

More as it progresses.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

Had a good set off.

Spent most of it in the dungeon.

Although I did find some time to get outside to cut some MDF.

Got my Press frame together and did a test suck.

Not quite as impressive as OAP's but success nonetheless.

Decided to just use a thru fitting too lazy to make the vacuum table just yet.

Had to do a bit of thermo molding with a blow dryer to get the vinyl to pull down tight to the huge tip mold but it worked great.

Still have a couple pointy bits to take care of so stuck some cardboard in to protect the plastic for it's trial run!

After I tested to make sure it worked I put some hinges on the backside, a handle on the front and a hook on the wall to hold it up out of the way.

This isn't going to be very easy to use with other molds but i think I should be using this mold for a while.

4 more days of work then next set off I should be able to get cores made up and edges bent! New touring skis are getting close

sam

Spent most of it in the dungeon.

Although I did find some time to get outside to cut some MDF.

Got my Press frame together and did a test suck.

Not quite as impressive as OAP's but success nonetheless.

Decided to just use a thru fitting too lazy to make the vacuum table just yet.

Had to do a bit of thermo molding with a blow dryer to get the vinyl to pull down tight to the huge tip mold but it worked great.

Still have a couple pointy bits to take care of so stuck some cardboard in to protect the plastic for it's trial run!

After I tested to make sure it worked I put some hinges on the backside, a handle on the front and a hook on the wall to hold it up out of the way.

This isn't going to be very easy to use with other molds but i think I should be using this mold for a while.

4 more days of work then next set off I should be able to get cores made up and edges bent! New touring skis are getting close

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

cool.

So... what is that, vinyl? - What gauge? the top skin. Wouldn't think vinyl would last many pressings but it may be cheap.

And how are you creating a seal? The double gasket material.

Looks great. Nice work.

Does the compressor run or some?

Has anyone or you looked into increasing the vacuum with a stack of water basically? I don't know what they call it.

So... what is that, vinyl? - What gauge? the top skin. Wouldn't think vinyl would last many pressings but it may be cheap.

And how are you creating a seal? The double gasket material.

Looks great. Nice work.

Does the compressor run or some?

Has anyone or you looked into increasing the vacuum with a stack of water basically? I don't know what they call it.

Yup, vinyl, 30mil.

Think waterbed material, maybe a little stiffer.

Should last through a few pressings.

Wanted to do polyurethane but it was twice as much!

Still can't afford actual silicone vacuum blanket.

I keep emailing manufacturers telling them I'm a poor hobby builder and maybe they could part with a sample or roll end but no such luck.

When I first started this venture sealant tape was about $4 a roll.

Now the best price i can find is $6 if you buy 10 rolls!

I gave up on vacuum bagging film a while ago + started using medium duty poly. But the sealant tape was adding another $6 every ski.

Got to be better for the environment than throwing away all the sheets of plastic and sealant tape.

The gasket material is sealing the vinyl to the frame and the frame to the table.

My vacuum pump is pretty heavy duty, will pull max vacuum, which at my altitude (3500') is about 28"hg.

Vacuum is limited to atmospheric pressure. At sea level you can get about 29.8 inches of mercury, the higher you go the less atmospheric pressure pushing down on you or your layup.

You can create vacuum with a column of water, but still can't create more pressure than whats available in the atmosphere.

Bottom line is... I'm stoked.

sam

Think waterbed material, maybe a little stiffer.

Should last through a few pressings.

Wanted to do polyurethane but it was twice as much!

Still can't afford actual silicone vacuum blanket.

I keep emailing manufacturers telling them I'm a poor hobby builder and maybe they could part with a sample or roll end but no such luck.

When I first started this venture sealant tape was about $4 a roll.

Now the best price i can find is $6 if you buy 10 rolls!

I gave up on vacuum bagging film a while ago + started using medium duty poly. But the sealant tape was adding another $6 every ski.

Got to be better for the environment than throwing away all the sheets of plastic and sealant tape.

The gasket material is sealing the vinyl to the frame and the frame to the table.

My vacuum pump is pretty heavy duty, will pull max vacuum, which at my altitude (3500') is about 28"hg.

Vacuum is limited to atmospheric pressure. At sea level you can get about 29.8 inches of mercury, the higher you go the less atmospheric pressure pushing down on you or your layup.

You can create vacuum with a column of water, but still can't create more pressure than whats available in the atmosphere.

Bottom line is... I'm stoked.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

awesome. I meant to ask what is the gasket material?

could you not poor your own silicon blanket by getting the right rubber?

It might be tough, but those smaller hobbie companies really want to work with you to find the right silicon or rtv solution for your problem. Think movie people. Looks like that vinyl is a fine, fine solution.

could you not poor your own silicon blanket by getting the right rubber?

It might be tough, but those smaller hobbie companies really want to work with you to find the right silicon or rtv solution for your problem. Think movie people. Looks like that vinyl is a fine, fine solution.

It's, um, gasket tape.

http://www.veneersupplies.com/products/ ... -x-18.html

Used about <3/4 roll to go around 3 times.

sam

http://www.veneersupplies.com/products/ ... -x-18.html

Used about <3/4 roll to go around 3 times.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

Good impressive work on the press Sam!

You should really try to get that rubber i got. One could press whatever, and it gets back to it's original form! It seems it will last forever!

I've got my steel frame welded by a friend. But I decided to get it a little paint to lighten up the dull workshop...

I will post pictures next week when the paint has dried and its mounted again.

You should really try to get that rubber i got. One could press whatever, and it gets back to it's original form! It seems it will last forever!

I've got my steel frame welded by a friend. But I decided to get it a little paint to lighten up the dull workshop...

I will post pictures next week when the paint has dried and its mounted again.

OAC... I know what you mean now about the wood frame being too light.(although its pretty heavy  )

)

A metal frame would be even heavier.

This one turned a bit hour glass shaped when at full vacuum.

Both long sides probably pulled in 30mm or so.

The block where my fitting is started out with about 15mm space on either side and ended up touching the frame and the mold.

I might put a spacer block on both sides to prevent this.

It will also help to position my mold (as the vinyl is thermo molded in one position)

When the vinyl doesn't work any longer I will definitely buck up for a proper vacuum membrane. Hopefully next year!

sam

A metal frame would be even heavier.

This one turned a bit hour glass shaped when at full vacuum.

Both long sides probably pulled in 30mm or so.

The block where my fitting is started out with about 15mm space on either side and ended up touching the frame and the mold.

I might put a spacer block on both sides to prevent this.

It will also help to position my mold (as the vinyl is thermo molded in one position)

When the vinyl doesn't work any longer I will definitely buck up for a proper vacuum membrane. Hopefully next year!

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

Got some cores glued up this last set off.

You can see my ghetto sidewall clamp in the process of getting taken apart.

Essentially its 2 boards, each with 2 screws per core spaced evenly apart.

(a hair wider than the waist of the board with the side walls attached.)

I slide them together apply my epoxy (with a roller) then set each core between the screws.

Then once all the cores are in place I slide the two boards apart.

The taper in the core (sidecut) gets tighter as the boards with the screws get further apart.

then I adjust all the sidewall pieces so that they are fairly even with the cores.

(I leave the sidewalls longer so they get the snipe instead of the core)

Sometimes a slight warp will leave a bit of a gap. Most times an elastic band or 2 will fix this. I've also used fishing line to pull things together.

This is a very ghetto solution but I found that when clamping side walls with a traditional clamp they want to roll up and off.

Cores all ready to get cleaned up with the planer

The 2 pair on the right are aspen and fir with very beefy maple sidewall

The ones on the left are aspen and larch w/ maple sidewalls and are noticeably heavier.

(Still have about 100+ rough fir and larch 1x4s in a pile in the backyard when I find clear ones I pull them out for cores

Hope this all makes sense, and once again YMMV

sam

You can see my ghetto sidewall clamp in the process of getting taken apart.

Essentially its 2 boards, each with 2 screws per core spaced evenly apart.

(a hair wider than the waist of the board with the side walls attached.)

I slide them together apply my epoxy (with a roller) then set each core between the screws.

Then once all the cores are in place I slide the two boards apart.

The taper in the core (sidecut) gets tighter as the boards with the screws get further apart.

then I adjust all the sidewall pieces so that they are fairly even with the cores.

(I leave the sidewalls longer so they get the snipe instead of the core)

Sometimes a slight warp will leave a bit of a gap. Most times an elastic band or 2 will fix this. I've also used fishing line to pull things together.

This is a very ghetto solution but I found that when clamping side walls with a traditional clamp they want to roll up and off.

Cores all ready to get cleaned up with the planer

The 2 pair on the right are aspen and fir with very beefy maple sidewall

The ones on the left are aspen and larch w/ maple sidewalls and are noticeably heavier.

(Still have about 100+ rough fir and larch 1x4s in a pile in the backyard when I find clear ones I pull them out for cores

Hope this all makes sense, and once again YMMV

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

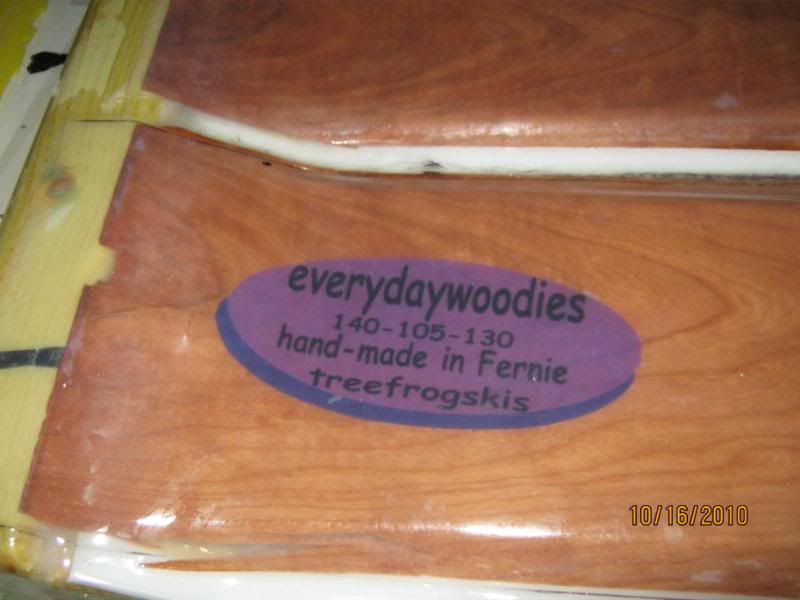

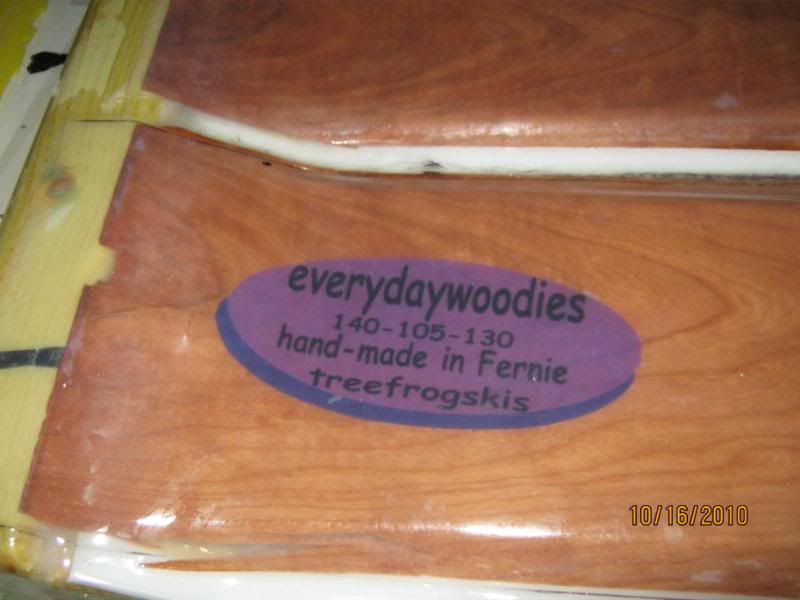

These are a little more turny than the last few I've made for myself.

I think final dimensions should be 140-105-130, about 22m radius

The running length on my mold is 1655mm.

So these will come out about 1835mm.

They never come out exactly to the dimensions I've planned but within a mm or so.

when I was building one at a time I could measure the first one then put dimensions on the second that would be fairly accurate.

sam

I think final dimensions should be 140-105-130, about 22m radius

The running length on my mold is 1655mm.

So these will come out about 1835mm.

They never come out exactly to the dimensions I've planned but within a mm or so.

when I was building one at a time I could measure the first one then put dimensions on the second that would be fairly accurate.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)

Yea!!

I got a pair pressed today.

Had a few issues but nothing i couldn't work around.

The new press works great!

Forgot core locators until I went to lay in my core.

I couldn't use my regular blocks as everything was too gooey.

So got out the trusty staple gun and stapled thru the tip and tail spacers to hold them where I wanted.

While rolling out the air and excess epoxy I managed to push my logo almost off the ski. (not sure how much will be left when I cut it out.)

Started to pull the new one out and found the tail needed to cook a little more.

Put the old electric blanket back on the tail.

( it's not quite long enough to cook the whole ski, but got all but the tail up to 140F)

Some details;

My most technical ski yet!!

core= aspen, fir, and maple sidewalls

2 layers 19oz triax 1 below/ 1 above the core

3 24k carbon tow under the core

aluminum binding plate w/ VDS above and below (and on the edges)

cherry veneer

2001 topsheet

flouro lime 4001 base

Got all prepped to build another one tomorrow.

Next one won't have the aluminum I'll use triax instead

+ walnut veneer

And I'm giving up the full wrap edges.

Getting way too pissed off trying to bend them into the tip mold

Looks like there are still a few air bubbles under the topsheet but they shouldn't be too noticeable once the bindings are mounted.

More pics when I get them cut out!

sam

I got a pair pressed today.

Had a few issues but nothing i couldn't work around.

The new press works great!

Forgot core locators until I went to lay in my core.

I couldn't use my regular blocks as everything was too gooey.

So got out the trusty staple gun and stapled thru the tip and tail spacers to hold them where I wanted.

While rolling out the air and excess epoxy I managed to push my logo almost off the ski. (not sure how much will be left when I cut it out.)

Started to pull the new one out and found the tail needed to cook a little more.

Put the old electric blanket back on the tail.

( it's not quite long enough to cook the whole ski, but got all but the tail up to 140F)

Some details;

My most technical ski yet!!

core= aspen, fir, and maple sidewalls

2 layers 19oz triax 1 below/ 1 above the core

3 24k carbon tow under the core

aluminum binding plate w/ VDS above and below (and on the edges)

cherry veneer

2001 topsheet

flouro lime 4001 base

Got all prepped to build another one tomorrow.

Next one won't have the aluminum I'll use triax instead

+ walnut veneer

And I'm giving up the full wrap edges.

Getting way too pissed off trying to bend them into the tip mold

Looks like there are still a few air bubbles under the topsheet but they shouldn't be too noticeable once the bindings are mounted.

More pics when I get them cut out!

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)

Best of luck to you. (uneva)