Error

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

amazing

lost for words!

MonkeyCAM and SnoCAD - https://github.com/mikemag

Ski binding mounting https://github.com/splitn2/DrillSki

Richard Harcourt | www.splitn2.com | Christchurch New Zealand

rich@splitn2.com | www.facebook.com/splitn2

Ski binding mounting https://github.com/splitn2/DrillSki

Richard Harcourt | www.splitn2.com | Christchurch New Zealand

rich@splitn2.com | www.facebook.com/splitn2

Well done on getting to press your first skis.

I think that a lot of the fact that your ski press hasn't exploded yet is because you actually did take the good advice being offered by experienced members on the forum. You used the 3 vertical supports to brace it as suggested etc etc.

The fact it started to creak when you inflated it is pretty worrying.

Remember that cranking the press up isn't a competition. There is no real point using 70psi if it is straining your press and molds. It is just dangerous. Just press at a lower pressure. The vast majority of people on here are using 40-50psi or even less with vacuums and you can see the quality and durability of the skis being produced. In fact a lot of companies only press at lower PSI, for example Folsom Customs press at 45PSI and their presses are full blown ibeam construction.

It's not worth damaging your press or yourself just so you can say "I got the bladders up to 70PSI". Noone is impressed by that. People are impressed by seeing great looking skis at the end. Good luck.

I think that a lot of the fact that your ski press hasn't exploded yet is because you actually did take the good advice being offered by experienced members on the forum. You used the 3 vertical supports to brace it as suggested etc etc.

The fact it started to creak when you inflated it is pretty worrying.

Remember that cranking the press up isn't a competition. There is no real point using 70psi if it is straining your press and molds. It is just dangerous. Just press at a lower pressure. The vast majority of people on here are using 40-50psi or even less with vacuums and you can see the quality and durability of the skis being produced. In fact a lot of companies only press at lower PSI, for example Folsom Customs press at 45PSI and their presses are full blown ibeam construction.

It's not worth damaging your press or yourself just so you can say "I got the bladders up to 70PSI". Noone is impressed by that. People are impressed by seeing great looking skis at the end. Good luck.

Don't wait up, I'm off to kill Summer....

-

twizzstyle

- Posts: 2207

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

My first mold was just glued together, it lasted for two skis and then fell apart, presumably from the thermal cycling breaking down the glue.a.badner wrote:i regret doing that actually. because all the glue in my bottom mold cracked and stopped adhering. which sucks because i had to think of a better way to put it toogether.

and the skis., theyre not skis. those are the flex tests i was talking about earlier. but thats fine.

This is why people bolt their molds together.

-

twizzstyle

- Posts: 2207

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

That's fine for adjusting the length (I've thought about almost the exact same thing actually, might work great). But for the mold ribs themselves, those should be held together by threaded rod (can glue them as well).a.badner wrote:i was actually thinking about making a dowel system for molds.

so you have you base mdf board. then drill holes in for dowels. and then put dowels in the molds themselves.

it would be easy to adjust, easy to make. will it last longer than glue though?

Some people have probably had success without threaded rods (my last mold didn't have them, and lasted four skis so far, still looks great), but they guarantee your mold will last forever. Peace of mind can be a good thing. (I'm currently making a new mold for my next pair so I'm in the heat of this right now)

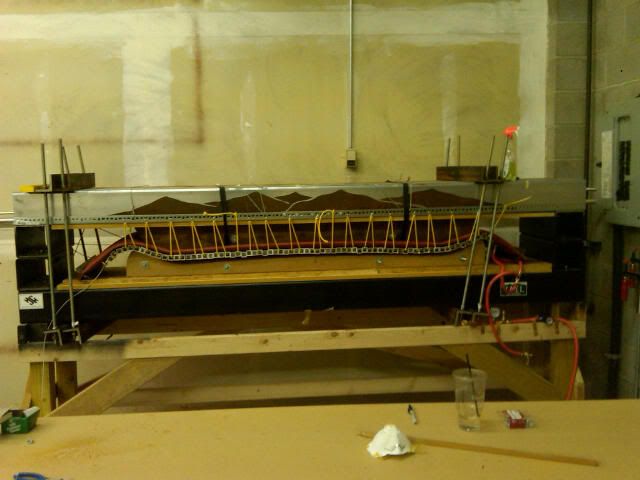

See the threaded rod on this mold (not mine obviously)

hey forum, i need some help.

two things.

1. ok. so. i was doing edge bending today. the bending was fine. i used a torch to light it up and the bent them in with pliers and hand. but, gluing went horribly. i bought some standard crazy glue. came in little tubes. and i clamped on the edges. put the glue down. then left it for fifteen minutes. came back and the glue was still wet. so i left, came back in half an hour. still wet. then went to work for four hours. came back the glue looked dry, so i took off the clamps and it held in for a few seconds. but the the edges just fell off. so now i have base material covered in crazy glue. and bent edges. am i using the wrong glue?

which of theese glues should i be using?

http://www.mcmaster.com/#loctite-super-glue/=9i85ii

and

2. (for the physicists) ok.

i am in grade eleven. so i am doing kinematics in physics and need some help.

ok.

when i have 2d vector. both angles and directions are given. but no velocities. how would i find the overall velocity? should i use a variable?

so c^2=x^2+y^2

sin/cos/tan @ = y^2/x^2 ( @ being feta)

i dont know what do. and i have a mid term in physics on monday. help is greatly appreciated.

thanks, adam

two things.

1. ok. so. i was doing edge bending today. the bending was fine. i used a torch to light it up and the bent them in with pliers and hand. but, gluing went horribly. i bought some standard crazy glue. came in little tubes. and i clamped on the edges. put the glue down. then left it for fifteen minutes. came back and the glue was still wet. so i left, came back in half an hour. still wet. then went to work for four hours. came back the glue looked dry, so i took off the clamps and it held in for a few seconds. but the the edges just fell off. so now i have base material covered in crazy glue. and bent edges. am i using the wrong glue?

which of theese glues should i be using?

http://www.mcmaster.com/#loctite-super-glue/=9i85ii

and

2. (for the physicists) ok.

i am in grade eleven. so i am doing kinematics in physics and need some help.

ok.

when i have 2d vector. both angles and directions are given. but no velocities. how would i find the overall velocity? should i use a variable?

so c^2=x^2+y^2

sin/cos/tan @ = y^2/x^2 ( @ being feta)

i dont know what do. and i have a mid term in physics on monday. help is greatly appreciated.

thanks, adam

-

skidesmond

- Posts: 2338

- Joined: Tue Apr 07, 2009 3:26 pm

- Location: Western Mass, USA

- Contact:

ya the crazy glue is pretty old, but i know it works. i got some on fingers, and couldnt split them. and when i did some skin got transferred fomr one to another.skidesmond wrote:Did you clean the edges after you put the torch to them? Could be old super glue too. Can't say I've ever had this problem. The bases can be cleaned off with a little scraping w/ a razor and acetone.

Can't help you on physics.

and i cleaned the bases with nail polish remover. its similar. pure acetone is only available to buy industrially, and for science batches. instead i went to wal-mart and bought ethyl acetate.

at first, i thought i put the edge on the non-abraded side. but it was on the abraded side.

and come on, what do you do when our children come to you for help with physics?

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm