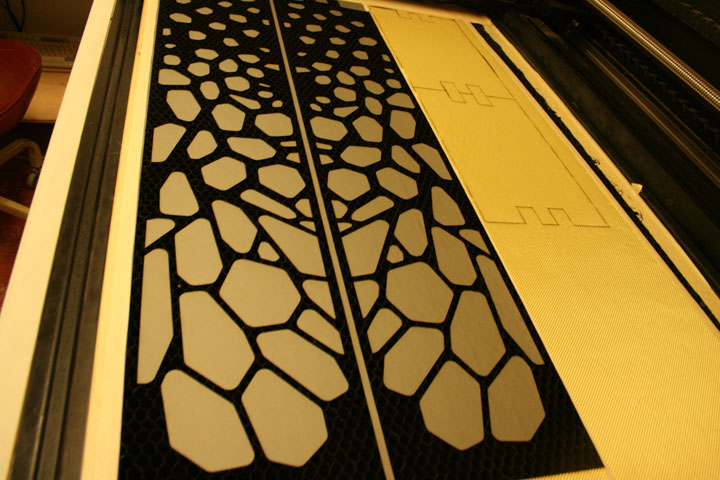

I am trying to use take advantage of the CNC adn other precise tools to eliminate inconsistency. so most of my construction process pictures will be dealing with the CNC and possibly the lasercamm later.

So here is the ski I designed....... 3d modle in Solidworks.

Design was inspired by the conditions that I deal with sking in West Virginia. Sometime lots of pow, Sometime ice and groomers.

Here is my mold design.... 30 mm of camber in running length, I think around 6 or 7 cm of rise in the reverse camber tip and tail.

Used the CNC to Cut out 8 profiles.......will press one ski at a time.

[imghttp://media.newschoolers.com/uploads/cache/images/1223591036-636998-600x400-12235887799.jpg[/img]

So I need to do some sanding and finishing plus stick some dowles through alignment holes and I will be done with that. What do you guys suggest for a top sheet on it?

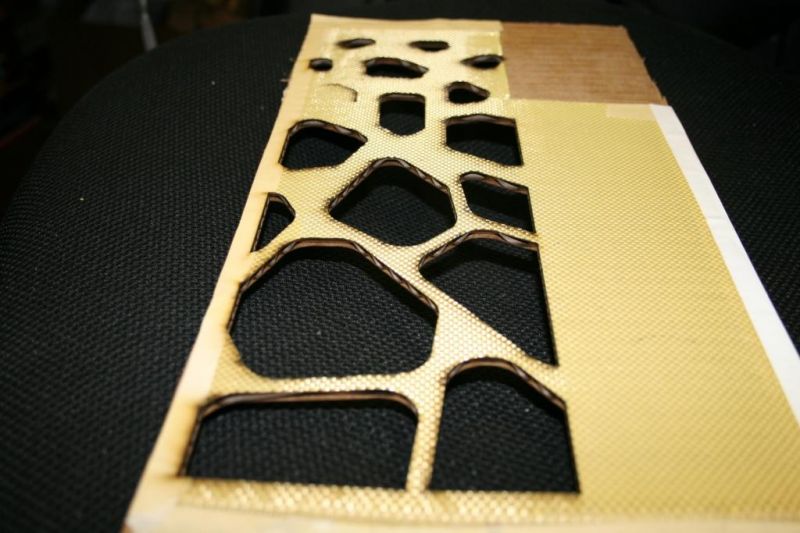

Next came milling out the core shape. Oh, and Im using bamboo planks for the material. Got it at 4windsbamboo.com. There will be a 1 cm base/core offset.

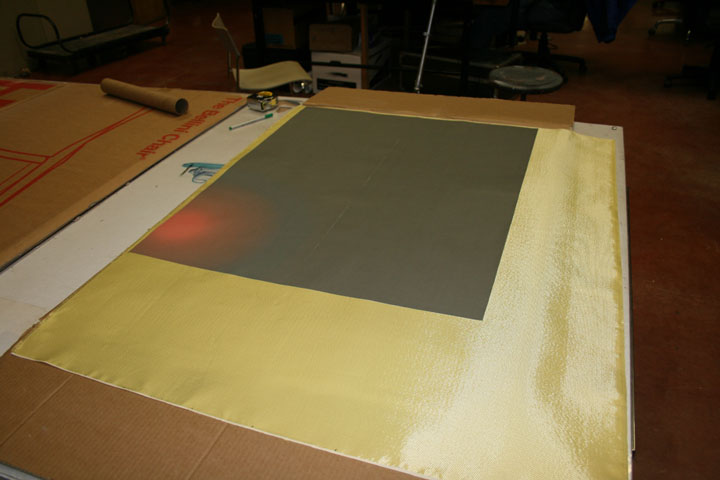

Milled the base material next. I used double sided carpet tape to stick it to the CNC bed, it held it amazingly but did not want to come off and left residue on the base which I used goo gone to get off.

And on the fith day god made sidewalls. The material was warped so I had to figure out how to rip it into staight pieces. Answer..Epoxy, scrap wood, and clamps.

I forgot to take pictures while I epoxied the sidewalls onto my cores, but here is what I did. Sanded sides, flame treated with torch, and lightly sanded again. I then used West System 105 resin with 207 hardener to to bond the sidewalls on, clamping every 4 to five inches. The bond seemed great when I checked it a day or two later.

Apparenlty not though. One side wall started t delaminate when I ran it through the Planar a couple of time while the other held. we put the good core with sidewalls back on the mill to have a go at profiling.

The sidewalls held up to an initial trimming process we ran before the actual profiling process, but the side wall Delaminated at the start of the profiling. However we made a programming mistake and the CNC started the pass at about 1/4 in deep and hit the tip of the sidewall first. so this may have been the culprit, but the other core delamed ont the planar so its hard to tell.

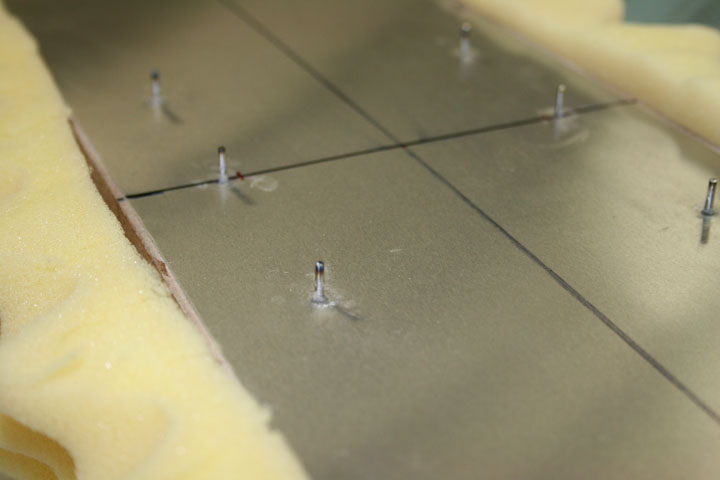

core w/sidewalls in a jig for screwing to bed

ouch! the frayed edges are from the initial trim process I mentioned above. The delamination happened when the bit dug into the end of the sidewall you can see there.

So any tips/suggestion from you experienced builders out there? It seemed like when I flame treated the p-tex it just made the surface smooth and unlikely to bond. did I heat it to long? or should I not flame treat at all and just abraid roughly?

more coming soon.