HELP?!? Haha, dye sublimation press...

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

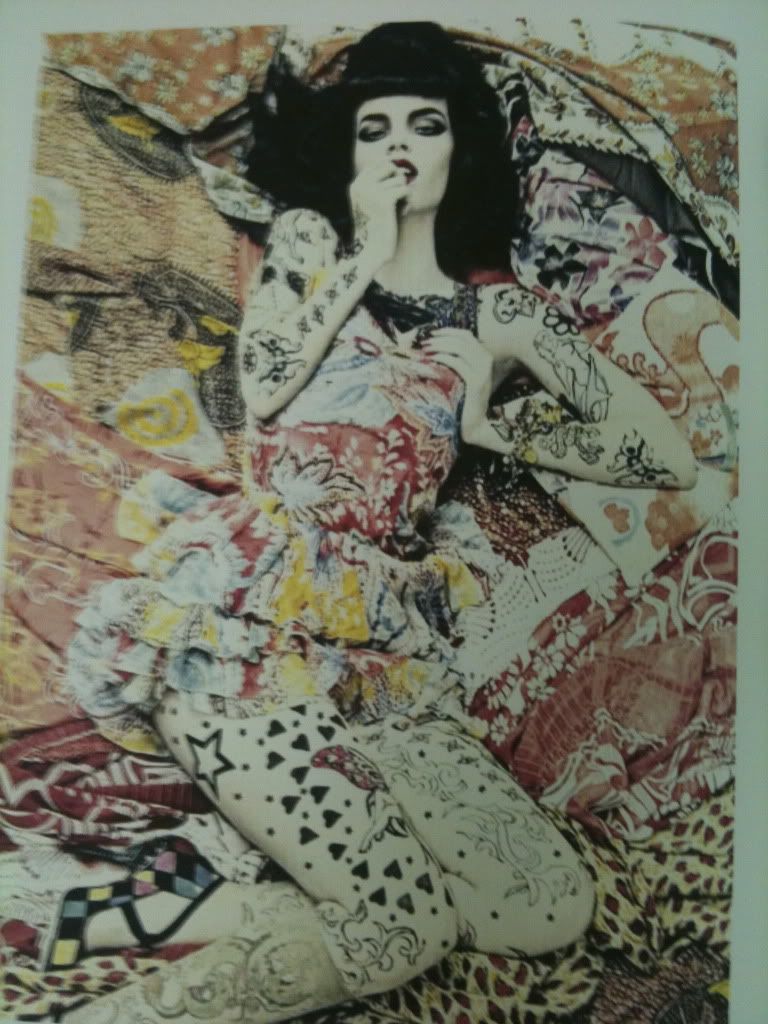

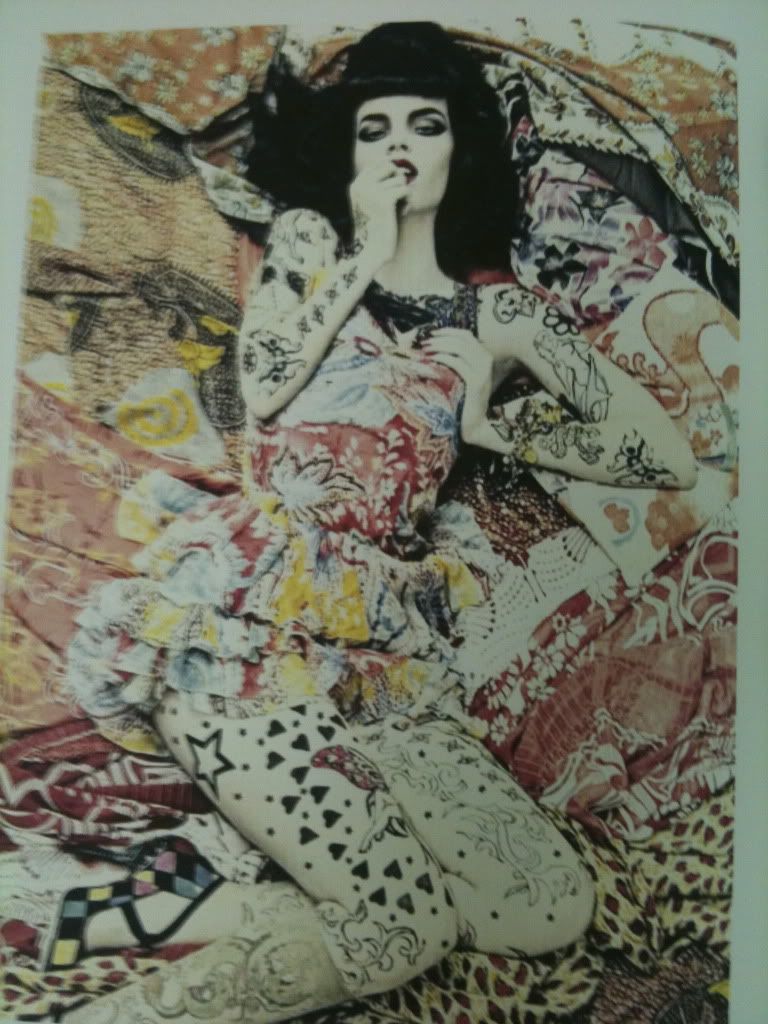

OMG Rich...photos are totally different. Here's a pic of the sublimation ink rendition:

Here's the subbed version 150 ppi fast quality RGB 280f @ 20psi for 40 minutes on Isosport 4160:

It's actually not as bad as it looks, iPhone sucks for photos (soft focus/3GS) but...GAAAHHHHHH!!!! Apparently there's just no end to the tunnel we have to throw ourselves down. Or...maybe all the ink made her skin turn green. That's it.

Here's the subbed version 150 ppi fast quality RGB 280f @ 20psi for 40 minutes on Isosport 4160:

It's actually not as bad as it looks, iPhone sucks for photos (soft focus/3GS) but...GAAAHHHHHH!!!! Apparently there's just no end to the tunnel we have to throw ourselves down. Or...maybe all the ink made her skin turn green. That's it.

"86% of the time it works 100% of the time".

Great to see the results - its a good template for testing and ironing out the kinks.

Comparing like to like is tricky, but it sounds like you have really good clarity. I'm getting what you can see in the middle of the second photo - I'll re-take the photo and replace later today. Do you pay attention to what the sublimation paper looks like, post print. Found this helpful.

I will spend a little more time looking at the timing - get it down to the right number of seconds (more or less, given that surrounding temperatures may vary). I think this is the primary factor and the only one I can really control with a reasonable degree of accuracy. I will see what effect the ppi has once I'm close to deciding timing.

20 psi - same, tried lower, but it didn't work for me.

PPI - just been letting the printer do its thing (epson 1400R)

40mins ... I want to keep it down to no more than ten otherwise the mdf heats up too much. My press is a little compromised by not being able to remove the print immediately.

This is as clear as the camera can get things, but it looks like I can still push for a bit more clarity. She's a little pink, which I will need to solve, because this is saturating the image.

Comparing like to like is tricky, but it sounds like you have really good clarity. I'm getting what you can see in the middle of the second photo - I'll re-take the photo and replace later today. Do you pay attention to what the sublimation paper looks like, post print. Found this helpful.

I will spend a little more time looking at the timing - get it down to the right number of seconds (more or less, given that surrounding temperatures may vary). I think this is the primary factor and the only one I can really control with a reasonable degree of accuracy. I will see what effect the ppi has once I'm close to deciding timing.

20 psi - same, tried lower, but it didn't work for me.

PPI - just been letting the printer do its thing (epson 1400R)

40mins ... I want to keep it down to no more than ten otherwise the mdf heats up too much. My press is a little compromised by not being able to remove the print immediately.

This is as clear as the camera can get things, but it looks like I can still push for a bit more clarity. She's a little pink, which I will need to solve, because this is saturating the image.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Bumping this cause im doin it.

Any thoughts?

Do the different inks sub at diff temps?

I see donek doin a test at 1min at 350f.

I got a blanket good to 190c and I got a epson 1400 printer and I am gonna get this cis.

http://www.ebay.com/itm/260757315160

and this transfer paper :

http://www.ebay.com/itm/161329718293

and this ink:

http://www.ebay.com/itm/261455129872

I thought I was shooting for 350F

ink says 400F

I need to know if this will work or if it will be a fail.

The sawgrass stuff must be made of magic, its so expensive.

Tips, tricks, techniques?

The blanket I got is only 3850 watts so max temp is 190C

Any thoughts?

Do the different inks sub at diff temps?

I see donek doin a test at 1min at 350f.

I got a blanket good to 190c and I got a epson 1400 printer and I am gonna get this cis.

http://www.ebay.com/itm/260757315160

and this transfer paper :

http://www.ebay.com/itm/161329718293

and this ink:

http://www.ebay.com/itm/261455129872

I thought I was shooting for 350F

ink says 400F

I need to know if this will work or if it will be a fail.

The sawgrass stuff must be made of magic, its so expensive.

Tips, tricks, techniques?

The blanket I got is only 3850 watts so max temp is 190C

sammer wrote: I'm still a tang on top guy.

http://www.aliexpress.com/item/6-color- ... 51683.html

Takes a bit longer to ship unless you use FedEx or DHL.

Takes a bit longer to ship unless you use FedEx or DHL.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Does the transfer paper kind or quality matter? Can I sub right after I print or do I have to wait a day?

What's the optimal time like 3min?

I'm gonna sand which between 2. .25 inch steel plates

Should I get a silicon bumper sheet? I'm only using one 7 inch wide bladder I hope.

Blanket is here today.

Whoop. Whoop.

What's the optimal time like 3min?

I'm gonna sand which between 2. .25 inch steel plates

Should I get a silicon bumper sheet? I'm only using one 7 inch wide bladder I hope.

Blanket is here today.

Whoop. Whoop.

sammer wrote: I'm still a tang on top guy.

Don't know if the transfer paper matters...i'm buying the cheapest I can find, so I have nothing to compare to. No complaints though.

You can sub after the ink is dry a couple minutes after printing.

There is no one single optimal time. You need to make some test samples to work out a time/heat combo that works well for your inks/paper/substrate. General rule is that you can sublimate at lower temps by increasing the time and vice versa.

Dunno about the silicone sheet...I have a vacuum press.

You can sub after the ink is dry a couple minutes after printing.

There is no one single optimal time. You need to make some test samples to work out a time/heat combo that works well for your inks/paper/substrate. General rule is that you can sublimate at lower temps by increasing the time and vice versa.

Dunno about the silicone sheet...I have a vacuum press.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Yeah please doMontuckyMadman wrote:thanks Ill post some pics in here when my evil creation is finished.

Also Chris if you have pics of your vacuum setup I'd be curious to see the details ! (or if it's already there I'll have to search :p)

A bad day skiing is always better than a good one at work...

-

prospectsnow

- Posts: 141

- Joined: Sun May 02, 2010 8:21 pm

- Location: Sacramento, Ca

- Contact:

Hey montucky, you are on the right track.

I would suggest not using steel plates. Use aluminum because it distributes heat over the whole platten. Also go thicker like 1/2 inch plates.

hot/cold spots, plate warp/distortion, uneven pressure, will all ruin your day.

I would suggest not using steel plates. Use aluminum because it distributes heat over the whole platten. Also go thicker like 1/2 inch plates.

hot/cold spots, plate warp/distortion, uneven pressure, will all ruin your day.

We have snowboard and kiteboard build kits!

https://prtahoe.com/collections/build-kits

https://prtahoe.com/collections/build-kits

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

<bump>

Montucky......any progress? Anyone else have any stories/pics?

I have ink, paper, printer, 100m pbt. Still need some metal sheets, and enough Mdf to fill up the ski press opening before I can experiment.

Question......given size and watts of heat blankets how does one determine how much heat a blanket will put out?

Montucky......any progress? Anyone else have any stories/pics?

I have ink, paper, printer, 100m pbt. Still need some metal sheets, and enough Mdf to fill up the ski press opening before I can experiment.

Question......given size and watts of heat blankets how does one determine how much heat a blanket will put out?

-

amidnightproject

- Posts: 378

- Joined: Wed Nov 04, 2009 10:59 am

- Location: Portland Area, Maine

- Contact:

Seems like there are a few of us in the process of figuring this out right now too.

I'm purchasing inks at the moment. Have a heatblanket ready to go that needs electronics. I'll probably piggy back off my press PID for the time being.

going to retrofit my original ski press for sub since it doesn't need much pressure.

I'm purchasing inks at the moment. Have a heatblanket ready to go that needs electronics. I'll probably piggy back off my press PID for the time being.

going to retrofit my original ski press for sub since it doesn't need much pressure.