Bent Green Things 13/14

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

SleepingAwake

- Posts: 175

- Joined: Mon Oct 11, 2010 11:06 pm

- Contact:

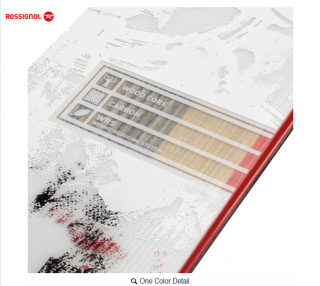

This is pretty standard in ski industry to have cores made of about 3mm wide strips! I guess it is easier to produce - like that they can use veneers instead of planks, so they can produce much bigger blocks without having troubles of putting one plank next to the other in order to get the with needed...

It maybe standard, but the rational for this has nothing to do with easy of production. This method ensures a structurally superior and consistent product. Bonding the stringers together using epoxy increases load bearing and fatigue resistance. Whether it improves the bond between the fibre and the core depends on whether you think epoxy bonds better to epoxy or woodglue. There is then a question as to whether bonding stringers using epoxy has an impact on vibration dampening

I read someplace that type of thin stringer core was supposed to be more torsionally stiffer.

I could not imagine gluing that up. So much glue... So many strips...ugh. I hate gluing up more than 7 strips at one time. I have glued up some thinner stringer cores once in a while to use up some left overs. I need to do it again, lots of skinny strips left over from this years builds.

The carbon is probably woven into the glass. I typically use 4-6 stringer of 12k tow to beef up the 19oz glass. I vary this depending on his stiff a ski I'm shooting for.

I could not imagine gluing that up. So much glue... So many strips...ugh. I hate gluing up more than 7 strips at one time. I have glued up some thinner stringer cores once in a while to use up some left overs. I need to do it again, lots of skinny strips left over from this years builds.

The carbon is probably woven into the glass. I typically use 4-6 stringer of 12k tow to beef up the 19oz glass. I vary this depending on his stiff a ski I'm shooting for.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

-

SleepingAwake

- Posts: 175

- Joined: Mon Oct 11, 2010 11:06 pm

- Contact:

Hey Gang I'm going to lay up another pair tomorrow night. I have a few questions.

1.) I remember reading about having the straight sections of the triaxial FB being up or down. If I remember correctly, the person suggested that the straight part of the fibers should be against the wood core. I did not pay attention to this on my first two layups. I want to nail it on this one. Am I correct?

2.) I know VDS is a must for the steel edges. However, is it really necessary against UHMW. I know there was one guy on there that has "100+ days on the skis" that forgot to put it in. Thoughts? I cut them for the layup but I question using it.

3.) this ski is only 11.2 in the mid. I'm throwing a "ton" of Carbon at this pair. So I'm not going to rabbet the base. I don't know what I was thinking when I was making this core last year. (I was on a ton of pain killers for my leg, maybe that was it) But it makes me wonder if my other two pair I made were this thin and that is why they are so "soft" compared to others that make theirs at 12.2mm. (maybe I have some flash sitting around that has the UHMW still attached...)

4.) I removed the Aluminum sheet above the top blanket and replaced it with a piece a melamine. Top blanket heated much faster!

5.) hummmm... wife goes to Yoga at 6... it's "yoga ski time" for me time at 7:55!

I think that's all I've got. Same top sheet as last year, still trying to dial in the process. I hope to have a new top sheet designed for this year but nothing yet.

6.) Has anyone ever talked to a binding rep to see about getting a "deal" on demo bindings? Instead of making all my friends skis it would be much easier (cheeper) to let them just ski a pair that has demo bindings on them. I know they are heavy and clunky but that will get more days on the ski than I'm able to put on them. I'm going to go to the ski expo this weekend and I'm hoping to make a few contacts.

cheers all, it's beer thirty.

1.) I remember reading about having the straight sections of the triaxial FB being up or down. If I remember correctly, the person suggested that the straight part of the fibers should be against the wood core. I did not pay attention to this on my first two layups. I want to nail it on this one. Am I correct?

2.) I know VDS is a must for the steel edges. However, is it really necessary against UHMW. I know there was one guy on there that has "100+ days on the skis" that forgot to put it in. Thoughts? I cut them for the layup but I question using it.

3.) this ski is only 11.2 in the mid. I'm throwing a "ton" of Carbon at this pair. So I'm not going to rabbet the base. I don't know what I was thinking when I was making this core last year. (I was on a ton of pain killers for my leg, maybe that was it) But it makes me wonder if my other two pair I made were this thin and that is why they are so "soft" compared to others that make theirs at 12.2mm. (maybe I have some flash sitting around that has the UHMW still attached...)

4.) I removed the Aluminum sheet above the top blanket and replaced it with a piece a melamine. Top blanket heated much faster!

5.) hummmm... wife goes to Yoga at 6... it's "yoga ski time" for me time at 7:55!

I think that's all I've got. Same top sheet as last year, still trying to dial in the process. I hope to have a new top sheet designed for this year but nothing yet.

6.) Has anyone ever talked to a binding rep to see about getting a "deal" on demo bindings? Instead of making all my friends skis it would be much easier (cheeper) to let them just ski a pair that has demo bindings on them. I know they are heavy and clunky but that will get more days on the ski than I'm able to put on them. I'm going to go to the ski expo this weekend and I'm hoping to make a few contacts.

cheers all, it's beer thirty.

for the glass: depends on what you want to to do. My buddy at Burton says that warp fibers (longitudinal biers) should go away from the core he says think "warp out" this should give you a stiffer laminate than if you go 45s out.

11.2 under for will be pretty soft. But if you are putting a lot of carbon in it might help, totally depends on what weight carbon and how much you actually use.

11.2 under for will be pretty soft. But if you are putting a lot of carbon in it might help, totally depends on what weight carbon and how much you actually use.

Last edited by vinman on Tue Nov 12, 2013 4:12 am, edited 1 time in total.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

-

SleepingAwake

- Posts: 175

- Joined: Mon Oct 11, 2010 11:06 pm

- Contact:

1) According composite theory it is better to put the biax layer on the core. Like that you have a smoother transition in the stiffness of each layer. And if your core is too thin then this is another reason to do so, because the fibers at 0° will be further away from each other.

2) Rubber on UHMWPE isn’t necessary – I know from skis from big manufacturers without rubber in the tips. But I made once some comparative tests on two identical skis once with rubber once without. It makes a hell of a difference in 3-point bending. We bent the tip of the ski with rubber basically the other way around so it had the same shape as before, just the wrong way, before it brake. It was unbelievable!

Can’t help on the other points tough…

Good luck and have fun in the shop!

2) Rubber on UHMWPE isn’t necessary – I know from skis from big manufacturers without rubber in the tips. But I made once some comparative tests on two identical skis once with rubber once without. It makes a hell of a difference in 3-point bending. We bent the tip of the ski with rubber basically the other way around so it had the same shape as before, just the wrong way, before it brake. It was unbelievable!

Can’t help on the other points tough…

Good luck and have fun in the shop!

-

MadRussian

- Posts: 712

- Joined: Thu Sep 30, 2010 12:32 pm

- Location: USA

http://www.skibuilders.com/phpBB2/viewtopic.php?t=31241.) I remember reading about having the straight sections of the triaxial FB being up or down.

Marker Royal family demo is not heavy and you can get them comparatively cheaper. I paid $120 for one on eBay. If you want demo this a way to go. Would've be nice to get going group buy.

btw I can get used look px12 demo for $60 if you're interested

I have not failed. I've just found 10,000 ways that won't work.

Thomas A. Edison

Thomas A. Edison

That's the one! thanks. I'll let you know on the binding deal. I picked up a used pair of skis at the end of the season for $50 that has demo bindings on them that I'll use for the first round.MadRussian wrote:http://www.skibuilders.com/phpBB2/viewtopic.php?t=31241.) I remember reading about having the straight sections of the triaxial FB being up or down.

Marker Royal family demo is not heavy and you can get them comparatively cheaper. I paid $120 for one on eBay. If you want demo this a way to go. Would've be nice to get going group buy.

btw I can get used look px12 demo for $60 if you're interested

+1 marker demos. Barely heavier than the regular alpine binding. The feel like the regular alpine bindings also. No extra stack height like other demos either.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

9oz 2" top and bottom. The last pair I did I uesd 2.5" 4.2OZ and I saw a 25% increase in longitudinal stiffness over a pair that had no carbon. This pair should be interesting. I'm not sure if increasing the carbon weight is exponential or linear. I guess I'll figure it out.Vinman wrote:11.2 under for will be pretty soft. But if you are putting a lot of carbon in it might help, totally depends on what weight carbon and how much you actually use.

9oz is pretty beefy, you might get away with 11.2mm with the 9oz...

I'm using 6.7oz uni carbon and 12.5 biax glass in my next layup plus some 12k carbon tow on roughly a 60 deg axis. I'm planning an 11.7mm core. This will be a first for me and it will be my personal set for the year. I'll let you know how it goes. Report back with you 9oz lay up results.

I'm using 6.7oz uni carbon and 12.5 biax glass in my next layup plus some 12k carbon tow on roughly a 60 deg axis. I'm planning an 11.7mm core. This will be a first for me and it will be my personal set for the year. I'll let you know how it goes. Report back with you 9oz lay up results.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com