First, I used a box cutter to get a purchase between the topsheet and the core. Then I used a putty knife and broke the bond little by little until the topsheet was separated from the core.

That took about 25 minutes to do one ski. On the next one I used the box cutter on the tip area. Then used the putty knife to peal back the tip. Then I just grabbed the topsheet and pealed it back. Came off just fine and took only a few minutes!

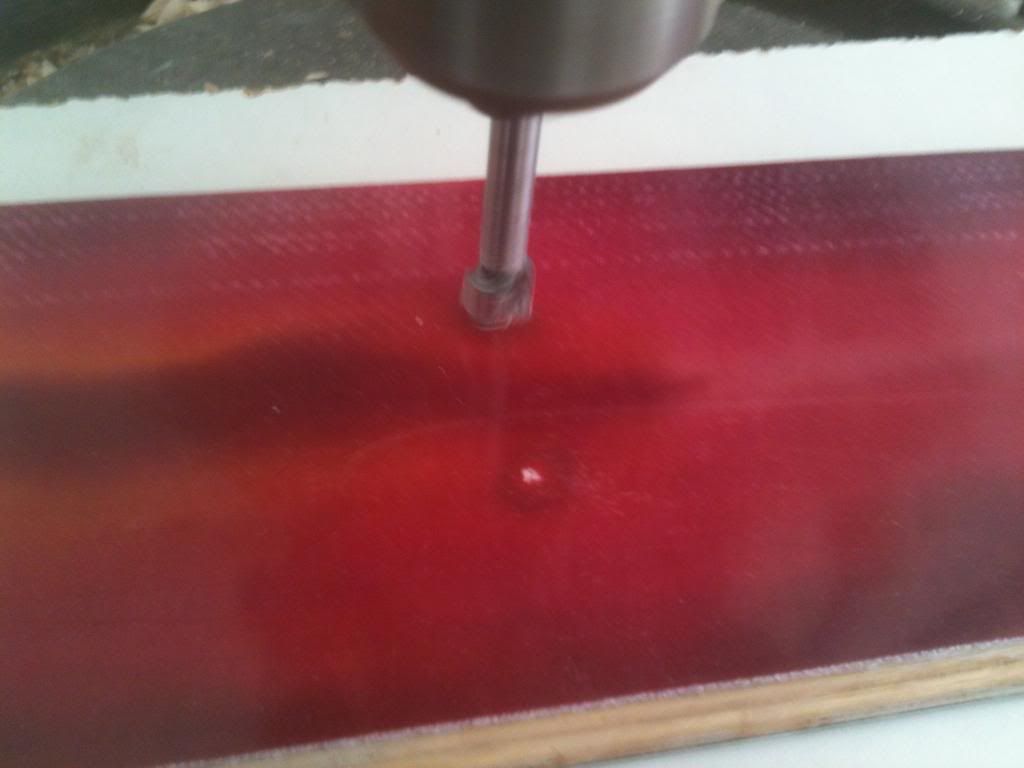

Now the fun part, Sanding the remaining glass from the core and then sanding down the core in an effort to soften the ski. First I use a belt sander.

Takes time and is a bit of work. So I opted for another route. This went a lot faster and was clean too!

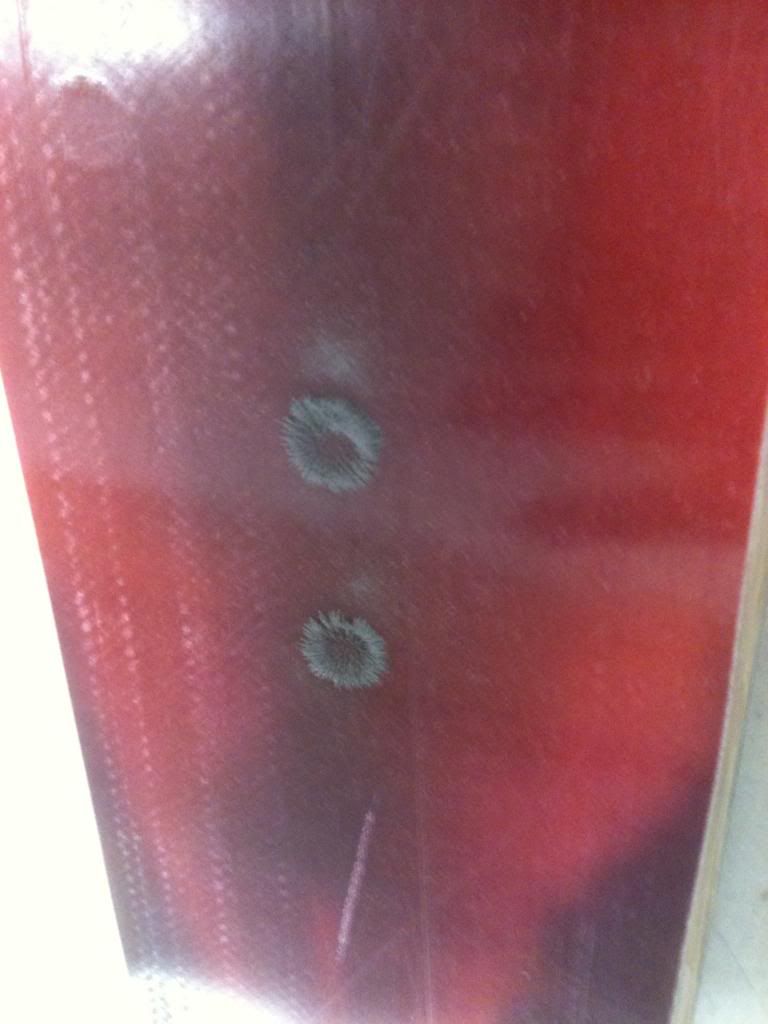

After sanding the core I needed to protect the inserts from epoxy so I covered them with the magnetic stickies.

Here are the cores all ready to go....

The rest is basic building... Here is the glass on the core...

Here is the new topsheet applied...

All wrapped and ready for the press...

In the press for the night....

It is kinda cold here (40's durring the day) so I use pellet stove to heat the room and help with the epoxy cure.

After skiing tomorrow I'll take them out and prep them for the snow! Hope they are a bit softer!

RA