Do you mean that I should shift the narrowest point back as much as 100 (or more) mm ? (I have size 28 cm boots). Sounds like a lot

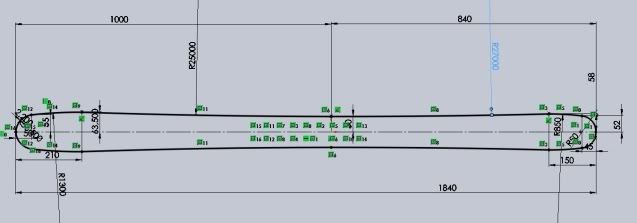

Hmmm... this might be a little tough to explain... and I'm sure that you already know some of this stuff, so bear with me here. For starters, for ski turns on firm snow, we ride the edge... and for turns on soft snow, we ride the base (for the most part on both counts). For the smoothest turns on firm snow, we want the arc that the ski edge makes (when the ski is weighted and placed on edge) to be the same radius in front and back of the pressure point on the ski... in other words, a consistent radius round arc. That way, the entire length of the ski edge passes through the same set of points on the snow surface (think perfectly carved turn). Likewise, for the smoothest turn on soft snow, we want the arc that the base makes to be the same in front and in back of the pressure point. To design a ski that does all this nearly perfectly requires a boatload of R&D time, and some fairly sophisticated testing equipment. The profile of the ski core and the radius (or radii) of the side-cut arc must be mated and fine tuned together. Dual radius side-cut arcs can be of benefit in this setting, but without proper analyzing equipment, multiple radius side-cuts will most likely create problems rather than provide benefits. However, for the hobby builder, simply using a single radius side-cut, placing the pressure point at the narrowest point of the side-cut, having a tail that is 10 mm narrower that the tip, and matching the ski's flex arc with the side-cut arc... will yield a nicely performing ski.

So, no, I'm not suggesting that you move the waist of your ski design back. I'm really just suggesting that you build a very basic ski this time, and then figure out a way to analyze the ski's final flex characteristics so that you can locate the center of the side-cut arc and the center of the flex arc (every 'back room' ski builder's big secret), mount the binding depending on the center of pressure of your particular skiing style, then test the skis to see if the skis feel balanced on the snow. If not, design another pair and move the arc centers fore or aft, then build and test the skis as before (if you simply moved the binding forward or back on the first pair, you'd alter the fore and aft arcs so that they would no longer be equal). Okay, yes, this is taking ski design to a pretty nerdy level. My point is that you really can't 'shot-gun' all of these design parameters on paper, and get it right the first time... and if you really do want to design and build a super nice turning ski, you really need to get all the various arcs working together (flex arc and side-cut arc at the same point on the ski, and same radius fore and aft), get the pressure point located correctly, and have the right amount of ski surface fore and aft of the pressure point. In reality, very few skis fit this strict criteria, but we still enjoy riding on them.

As far as pressure point goes, it helps if you can determine what part of your ski boot applies the most pressure to your skis. This is really more difficult than it sounds, as not all people have the same skiing 'style'. Tests have been done with high level skiers by placing pressure transducers in their ski boot footbeds, and then recording the point of highest pressure while skiing. Most athletes are quite surprised that they actually pressure in areas different than they predicted before the transducer tests. Some skiers pressure from the heels, some from the mid-foot, and some from the fore-foot. Tele skiers often do a bit of everything. The optimal bio-mechanical position of a skier's foot in a ski boot is way too big of a discussion (and way too opinionated) to get into, so I won't even start. Some skiers have a good intuitive sense of where their pressure point is, but I think lots of people have a difficult time being that in tune with their what their bodies are doing. But, in terms of getting your binding mount optimal, it may be useful to stand on your skis in your living room and make a mark on your boots where you think you're applying the most downward pressure. Then mount that part of the boot over the 'sweet spot' on the ski.

Regarding CF vs. FG, it sounds like you've done your homework and testing, so yes, go with what you've learned from your own good R&D work. My comments are based on simple and subjective hand flexing comparisons of skis I made with the different materials.

I look forward to seeing what you come up with. And ya, the jibber-jabber back and forth about ideas is always fun.

G-man