Here’s my design specs:-

1. 1570mm length – Which is my normal ride.

2. A bit wider that my normal build. 315mm at the widest approx.

3. Side cut radius less than normal about 7500mm I’m used to about 8000mm

4. Core from 1.6 – 7.0 – 6.2 – 7.0 – 1.6 ish.

5. Camber of 15 mm along the centre line

6. Base in 5 ‘facets’ – like a plywood dingy.

7. 740 gsm triax

8. Veneer top sheet with timber edges.

9. Paulowina core with end grain for insert sections.

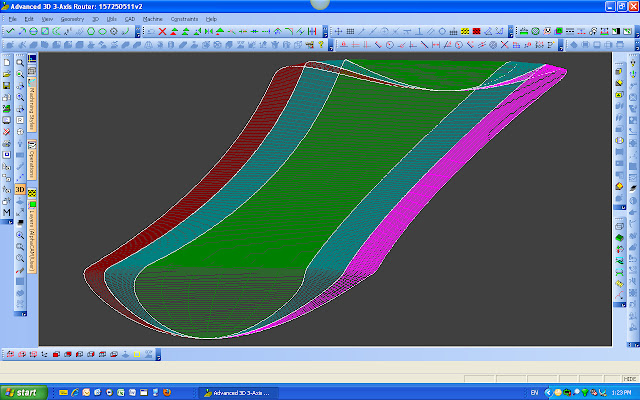

My thinking is a little like this.....Stick with a known length, thickness, camber, mix of materials, glass weight but make the changes to the base profile. My plan is to have a fairly standard cambered centre section and then have two raised sections along the length. The outer of the 2 raise sections will be approx 5mm raised from the centre section at the widest point of the board but flat across the centre. The second (working from the edge towards the centre) will be raised about 2mm from the centre section at the tips only remaining flat across the centre. The blend point from section to section will be concentric with the edge making a slightly larger radius for each from the previous edge. This will create a shape that is a bit like a plywood boat at the ends changing to flat in the centre.

The benefit, other than giving me new things to play with, will be to have 2 additional ‘hard chines’ (boat building terminology for the lines made by the joining of the faces) or contours in the base. Hopefully this should make for fast edge to edge transitions, less edge catches, some new dynamics from a convex flex pattern, and all that other marketing rubbish.....

The downside will be a more difficult to grind the base, possible reduced edge hold and lots of other unknown performance issues.

But I’m going to give it a go and see what happens. I just can’t accept that the best base shape for something as complex as a snow covered hill is flat from side to side. There is nothing flat about mountains so why make flat boards....unless of course they are easier, cheaper or just the way it’s always being done.

A view of the base

And looking from the front.

I’ll try to keep up the posts...... but it could be a bit hit and miss with the posting. C.