Metal edges for freestyle ski: What kind of steel?

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

ruudsjoukes

- Posts: 29

- Joined: Tue Feb 02, 2010 5:26 am

Already got that point, skipped it and we have a good discussion now where I wanted to go to.

The rails basically will 'crack' because the metal becomes 'thinner' once you ride rails.

Everytime you hit a rail little bits will be scrapped of since usually the steel of a rail is harder than your ski. This will continue happening untill your ski edge is basically round in stead of in angle. This means that there is less thickness to provide strength and prevent it from cracking.

So I'd say if you have a thougher or thicker rail you'd do better on freestyle skiis. Instead of the regular 2,5mm you could probably take a rail that would be 3,5 or 4mm so you get a certain 'space' where you can actually afford to have a round edge in stead of a angular edge.

This then brings me back to the following thought:

Said by head, not sure, burton i though... has an edge which is basically not straight but just a little S-shaped. If you take this desigen more down to the tip and tail and keep the middle section straight you could get a good carving ski with a middle section which could be perfect for railing!

Wonder what you guys think about this.

I'm going to try it out because that will probably be the best way to find out but it can't hurt to do some brainstorming.

Cheers!

The rails basically will 'crack' because the metal becomes 'thinner' once you ride rails.

Everytime you hit a rail little bits will be scrapped of since usually the steel of a rail is harder than your ski. This will continue happening untill your ski edge is basically round in stead of in angle. This means that there is less thickness to provide strength and prevent it from cracking.

So I'd say if you have a thougher or thicker rail you'd do better on freestyle skiis. Instead of the regular 2,5mm you could probably take a rail that would be 3,5 or 4mm so you get a certain 'space' where you can actually afford to have a round edge in stead of a angular edge.

This then brings me back to the following thought:

Said by head, not sure, burton i though... has an edge which is basically not straight but just a little S-shaped. If you take this desigen more down to the tip and tail and keep the middle section straight you could get a good carving ski with a middle section which could be perfect for railing!

Wonder what you guys think about this.

I'm going to try it out because that will probably be the best way to find out but it can't hurt to do some brainstorming.

Cheers!

Another thing to look at would be making a 3D base that just tapers upwards slightly at the edges, so the edges sit above the level of the rail when sliding and it's just base touching. It wouldn't be ideal for turning or stopping but may help assist in edge deterioration. Would also be fairly catch free which would be useful for a freestyle type ski.

I agree that it would be nice to have more of a choice in edge dimensions as well as base thickness. I would love to have more material to work with and would trade the extra weight for it any day.

My park skis always crack from sliding rails and I have tuned many skis in the shop that exhibit the same problems. I have yet to see a totally bombproof park ski that will last under continuous rail abuse.

I do remember a Rossi ski back from around 2002 or so called the Pow Air Grind. The edge curved into the base under foot so the actual side of the ski that you slid on was polyethylene. They probably had problems with this too since it is no longer offered. Plus it would probably suck and slide out in the pipe too.

Someone here needs to start a company selling extra beefy edges and base material. There are too few suppliers controlling the market anyways.

By the way, plural of ski is skis. For some reason people like to throw extra characters in there such as skies, skiis, ski's.

My park skis always crack from sliding rails and I have tuned many skis in the shop that exhibit the same problems. I have yet to see a totally bombproof park ski that will last under continuous rail abuse.

I do remember a Rossi ski back from around 2002 or so called the Pow Air Grind. The edge curved into the base under foot so the actual side of the ski that you slid on was polyethylene. They probably had problems with this too since it is no longer offered. Plus it would probably suck and slide out in the pipe too.

Someone here needs to start a company selling extra beefy edges and base material. There are too few suppliers controlling the market anyways.

By the way, plural of ski is skis. For some reason people like to throw extra characters in there such as skies, skiis, ski's.

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

i'm sure cdw would make any type of edge you want and for a great per unit cost. You just need to spend 1k min to do it.

the real question is the rubber gasket. VDS. Its totally ridiculous that this is completely 1 company. Maybe I just don't know the inside scoop and you can buy cheap neoprene and use that.

The real trick is to make this stuff and provide it cheaper.

the real question is the rubber gasket. VDS. Its totally ridiculous that this is completely 1 company. Maybe I just don't know the inside scoop and you can buy cheap neoprene and use that.

The real trick is to make this stuff and provide it cheaper.

-

ruudsjoukes

- Posts: 29

- Joined: Tue Feb 02, 2010 5:26 am

The rubber is made for demping. It's behavior is the same as any kind of demping material. Material that K2 uses under his bindings is called polyurathane, you can compare this material to the wheels of a longboard or a 'soft wheeled' skateboard which you can get in all kind of different grades of 'hardness'. This may lead you to another material than VDS, it's worth a shot and yes, you can get it nearly anywhere.

You can also google on slimewall, a certain material that is also used for impact by the snowboard company ride, is the same material I thought.

Back to the rails, I'm willing to try different types so let's come up with ideas. I asume that if you put VDS or polyU behind the rail, it will hit in when hit with too much pressure, the behavior of demping: Elastic

A hard rail with a rubber behind it... but will it bond, probably not.... Maybe create a rail with a 'hole' and pour rubber in there?

You can also google on slimewall, a certain material that is also used for impact by the snowboard company ride, is the same material I thought.

Back to the rails, I'm willing to try different types so let's come up with ideas. I asume that if you put VDS or polyU behind the rail, it will hit in when hit with too much pressure, the behavior of demping: Elastic

A hard rail with a rubber behind it... but will it bond, probably not.... Maybe create a rail with a 'hole' and pour rubber in there?

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Yeah man I know all of that. slimewall, poly yadayada

Its for bonding.

You can't find this material anywhere in this dimension, that the problem.

The same problem you have to achieve any of these goals, you have to get a big company to do the work for you and that costs money.

The dampest skis of all time had precracked edges that were fragile and hard to make. Call cdw about it.

Is english your second language?

Its for bonding.

You can't find this material anywhere in this dimension, that the problem.

The same problem you have to achieve any of these goals, you have to get a big company to do the work for you and that costs money.

The dampest skis of all time had precracked edges that were fragile and hard to make. Call cdw about it.

Is english your second language?

-

ruudsjoukes

- Posts: 29

- Joined: Tue Feb 02, 2010 5:26 am

Sorry about my spelling, yes it is. I'm dutch.

Let me come back to you on the slimewall and polyurathane, it's being quoted and it will be cheap, probably even cheaper than $2/meter. I work at a company with good contacts within the business so we'll find more on that. Just give me a chance on it.

Instead of me bothering CDW, share your info on it maybe? Would be great!

Let me come back to you on the slimewall and polyurathane, it's being quoted and it will be cheap, probably even cheaper than $2/meter. I work at a company with good contacts within the business so we'll find more on that. Just give me a chance on it.

Instead of me bothering CDW, share your info on it maybe? Would be great!

Yes slimewalls are polyurethane. I've got them on my DH2, I can't say I notice an enormous damping difference over ordinary sidewalls.

As MM said, the issue isn't with finding damping materials, there are rubber and plastic suppliers everywhere. The issue is with finding bondable damping materials, in particular stuff that is 0.1-0.5mm thick that can be used in the layup on top of the edges.

If you do manage to get hold of such stuff in a polyurethane then we would all be very interested.

As MM said, the issue isn't with finding damping materials, there are rubber and plastic suppliers everywhere. The issue is with finding bondable damping materials, in particular stuff that is 0.1-0.5mm thick that can be used in the layup on top of the edges.

If you do manage to get hold of such stuff in a polyurethane then we would all be very interested.

-

ruudsjoukes

- Posts: 29

- Joined: Tue Feb 02, 2010 5:26 am

So basically what you say is there is a need of thinner material of polyurethane or of a different material?

I can do research on the bonding materials but need to get it down a little specific. If you are willing to supply me with min/max thicknesses and width then I'll get a man doing the material research (he's an expert in it). The basics are:

- damping

- bonding epoxy

- ... ???

Help me out and I try to help you out on this one!

I can do research on the bonding materials but need to get it down a little specific. If you are willing to supply me with min/max thicknesses and width then I'll get a man doing the material research (he's an expert in it). The basics are:

- damping

- bonding epoxy

- ... ???

Help me out and I try to help you out on this one!

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

as contrary. free style skis actually use slimmer."Real" ski companies don't do anything special, other than wider edges (which does help)

dont bash on me for this. but heres a new schoolers videos

http://newschoolers.com/ns/content/viewvideo/id/343312/

-

ruudsjoukes

- Posts: 29

- Joined: Tue Feb 02, 2010 5:26 am

Info has been forwarded, now that's just waiting.

Didn't anyone just make 20 diff types of edges and hit them with a hammer to see whatever cracked first? I know there are a lot of people building skiis that have their own cnc machine, you can easily make edge patterns with it. Basically what I get is that edges crack because of the fact that there is not enough material to prevent the crack or... to absorb it in some kind of elasticy.

Could someone give me the seizes of a 'normal' ski edge?

What I basically thought about is combining a angular pattern with a T-shaped pattern. This way your edge would still have enough footage and still have a 'backbone' to prevent it from cracking. The places where they crack are usually within 1-2 feet from the center so the edgebending isn't the issue.

Prop. it's another trial/error thing but if someone has a good idea or knows which pattern lasts longer than others by experience...

Didn't anyone just make 20 diff types of edges and hit them with a hammer to see whatever cracked first? I know there are a lot of people building skiis that have their own cnc machine, you can easily make edge patterns with it. Basically what I get is that edges crack because of the fact that there is not enough material to prevent the crack or... to absorb it in some kind of elasticy.

Could someone give me the seizes of a 'normal' ski edge?

What I basically thought about is combining a angular pattern with a T-shaped pattern. This way your edge would still have enough footage and still have a 'backbone' to prevent it from cracking. The places where they crack are usually within 1-2 feet from the center so the edgebending isn't the issue.

Prop. it's another trial/error thing but if someone has a good idea or knows which pattern lasts longer than others by experience...

Building ski edges with a CNC machine would be a hugely inefficient and expensive process in my opinion.

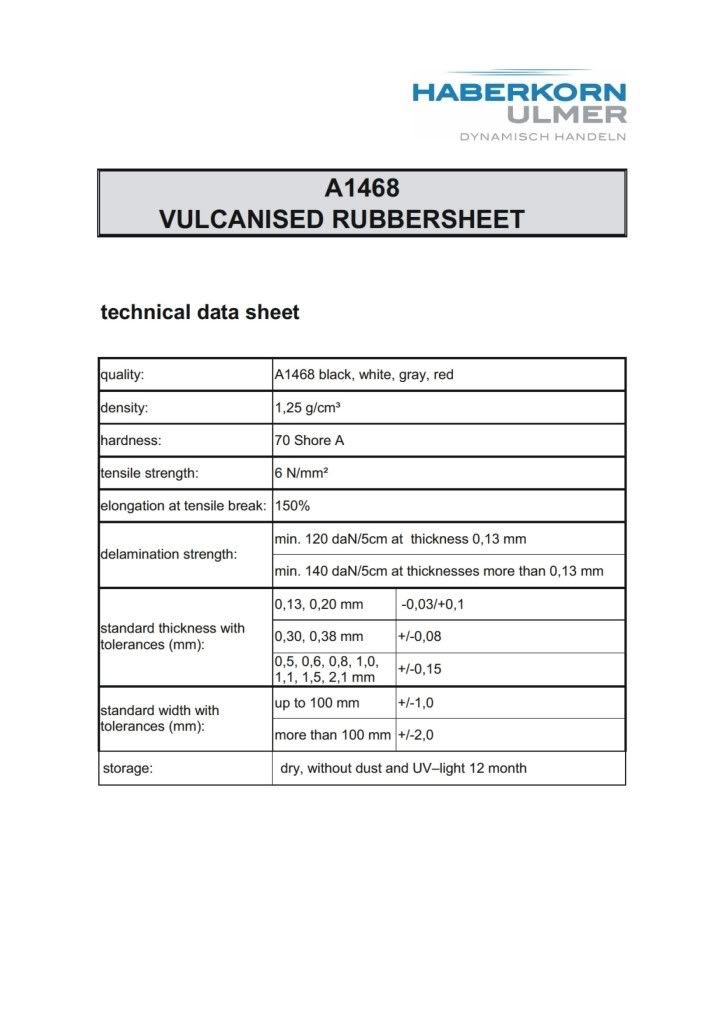

The edge portion cross section of edges on the ski builders store are 2mm tall, 2.2mm wide. The teeth/flange thickness is 0.65mm thick. The teeth extend inwards so that the total width of the edge is about 7.5mm

[/img]

[/img]

The edge portion cross section of edges on the ski builders store are 2mm tall, 2.2mm wide. The teeth/flange thickness is 0.65mm thick. The teeth extend inwards so that the total width of the edge is about 7.5mm

[/img]

[/img]Don't wait up, I'm off to kill Summer....

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

Did you even watch the video you posted?a.badner wrote:as contrary. free style skis actually use slimmer."Real" ski companies don't do anything special, other than wider edges (which does help)

dont bash on me for this. but heres a new schoolers videos

http://newschoolers.com/ns/content/viewvideo/id/343312/

They were not talking about the thickness or width of the edge. They were talking about the stamping pattern where the edge is attached, I can assure that most freestyle ski builders are using a thicker not thinner edge. The stamping pattern they were discussing is not something I have heard of before, but it does make some sense in regards to park skiing, but it has nothing to do with the comment you responded to.

And it's not as contrary. I suggest you pay more attention in school. The statement is "on the contrary".

Seriously you need to practice your written communication skills.

You might even try capitalization at the beginning of your sentences.