Cat-track discussion

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

Cat-track discussion

Dear all,

I am hanging around here for a couple of years now, builded multiple pairs of skis, I am building a CNC router at the moment, but.....

...one thing I don't understand is the use of a cat-track? Why are some of you using this system? Can anyone convince me of using one and explain me the benefits?

Buuk

I am hanging around here for a couple of years now, builded multiple pairs of skis, I am building a CNC router at the moment, but.....

...one thing I don't understand is the use of a cat-track? Why are some of you using this system? Can anyone convince me of using one and explain me the benefits?

Buuk

Make things as simple as possible, but not too simple

- Dutchjibber

- Posts: 19

- Joined: Fri Mar 17, 2006 1:07 am

- Location: Delft, The Netherlands

Hoi Buuk,

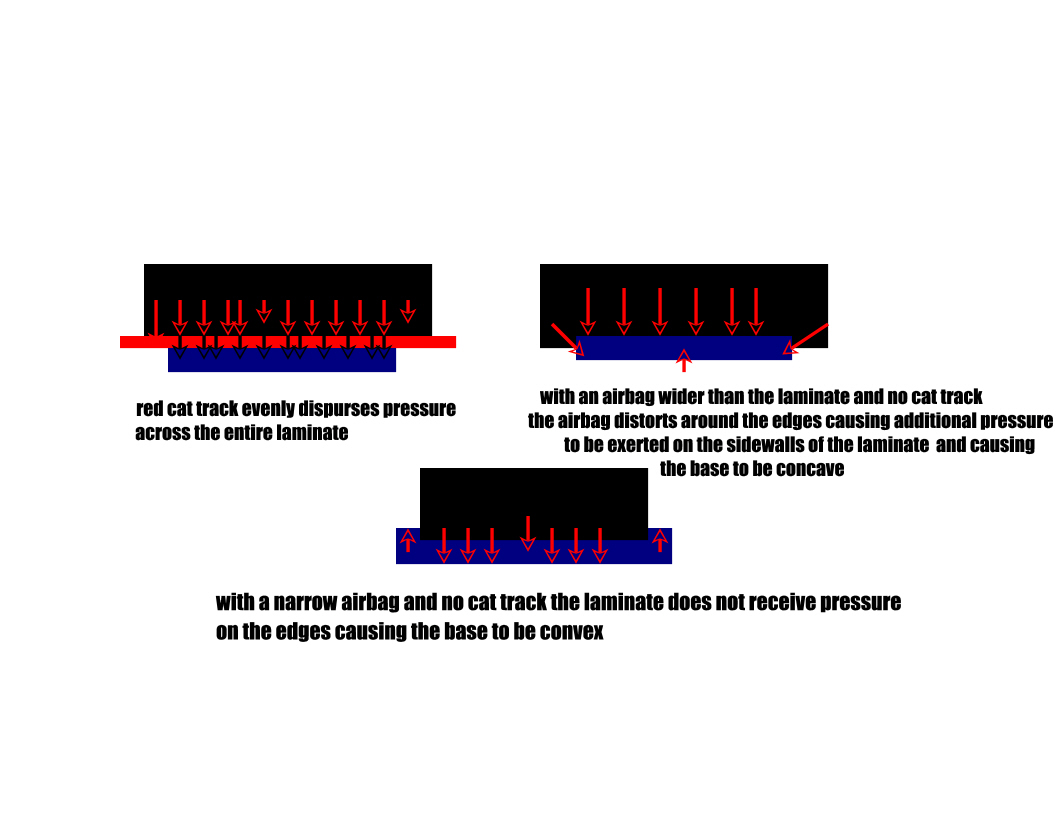

The reason why we opted for a cat-track is because we are using three small diameter firehoses for pressing 2 skis at the time. because of the small diameter, the bladders do not fully enclose the skis so the cat track ensures an even distribution of the pressure.

Also, the flat surface of the cat track allows the use of a heat blanket on the top side too.

I think it also reduces the risk of shifing bases as the cat track only moves vertically.

If your bladder is wide enough and you are not using a heat blanket, I think not using a cat track shouldn't be a problem. As we are just starting skibuilding, we wanted to get rid of as many insecurities as possible. The cat track methos seems to work for most people, so this seemed like a safe option.

Groeten, Bart

The reason why we opted for a cat-track is because we are using three small diameter firehoses for pressing 2 skis at the time. because of the small diameter, the bladders do not fully enclose the skis so the cat track ensures an even distribution of the pressure.

Also, the flat surface of the cat track allows the use of a heat blanket on the top side too.

I think it also reduces the risk of shifing bases as the cat track only moves vertically.

If your bladder is wide enough and you are not using a heat blanket, I think not using a cat track shouldn't be a problem. As we are just starting skibuilding, we wanted to get rid of as many insecurities as possible. The cat track methos seems to work for most people, so this seemed like a safe option.

Groeten, Bart

Please don't take the following as a personal attack, all I want is more knowledge about building ski's, to eliminate possible indistinctness and to share this knowledge... I hope to achieve this by starting this discussion.

@doughboyshredder:

- In your first picture (top left) you mention that the cat-track causes a uniform pressure distribution on the laminated ski, but in my opinion a cat-track creates a discontinuous pressure distribution compared to using a thin metal or aluminium plate on top of the ski. This because of all the seperate tubes. Especially in the tip and tail, which are the locations where one wants a uniform pressure the most because of delamination problems.

- Your second point (top right) about the sideward forces I am not sure about neither. At first when you are using a metal or aluminium plate (as stated above) you won't have this problem (or at least eliminated most of it). Secondly, if you disintegrate the sidewards forces excerted by the bladder, I can't imagine that the forces will be so high that the downwards forces won't counteract this effect.

@Bart:

Hey Bart, how is your progress on ski building?

In your case, when the bladder isn't wide enough I totally agree on using a cat-track! But about the shifting I don't agree, you should fix your base and core properly to the bottom of your setup. And a cat-track will be able to dislocate the ski in the length direction if not secured properly, just like a metal plate.

I am looking forward to your comments...

Buuk

@doughboyshredder:

- In your first picture (top left) you mention that the cat-track causes a uniform pressure distribution on the laminated ski, but in my opinion a cat-track creates a discontinuous pressure distribution compared to using a thin metal or aluminium plate on top of the ski. This because of all the seperate tubes. Especially in the tip and tail, which are the locations where one wants a uniform pressure the most because of delamination problems.

- Your second point (top right) about the sideward forces I am not sure about neither. At first when you are using a metal or aluminium plate (as stated above) you won't have this problem (or at least eliminated most of it). Secondly, if you disintegrate the sidewards forces excerted by the bladder, I can't imagine that the forces will be so high that the downwards forces won't counteract this effect.

@Bart:

Hey Bart, how is your progress on ski building?

In your case, when the bladder isn't wide enough I totally agree on using a cat-track! But about the shifting I don't agree, you should fix your base and core properly to the bottom of your setup. And a cat-track will be able to dislocate the ski in the length direction if not secured properly, just like a metal plate.

I am looking forward to your comments...

Buuk

Make things as simple as possible, but not too simple

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

this is part of a discussion in Journals section as well.

Cat track or a THICKER PLATE is the best way to translate bag pressure to NORMAL FORCE pressure.

Pressure normal to the surface of your mold is what you desire.

If you use a plate or sheet that is too thin, it will deform over the ends of the sidewall, as it bends over the edges it could actually LIFT just inside these pinch points and cause voids.

Also, the second your top metal sheet is bent over the edge of the sidewall, it will be pretty much useless on your next ski/board. You would have to line it up exact to get it right again.

So if you dont desire using the cat track, you should use a pre-bent steel or aluminum, that is so thick that you would imagine it being able to withstand the forces of the bag and not bend where there is nothing underneath it to keep it from doing so.

A good combination of the steel bars, plus a moderately thick steel or aluminum: thick enough to not get bent or have board shape imprinted into it, but thin enough so that it conforms to the curve of the camber and tips. We have had success with 18ga steel, but i'm considering stepping it up to 16ga or aluminum slightly thicker than 16ga.

Cat track or a THICKER PLATE is the best way to translate bag pressure to NORMAL FORCE pressure.

Pressure normal to the surface of your mold is what you desire.

If you use a plate or sheet that is too thin, it will deform over the ends of the sidewall, as it bends over the edges it could actually LIFT just inside these pinch points and cause voids.

Also, the second your top metal sheet is bent over the edge of the sidewall, it will be pretty much useless on your next ski/board. You would have to line it up exact to get it right again.

So if you dont desire using the cat track, you should use a pre-bent steel or aluminum, that is so thick that you would imagine it being able to withstand the forces of the bag and not bend where there is nothing underneath it to keep it from doing so.

A good combination of the steel bars, plus a moderately thick steel or aluminum: thick enough to not get bent or have board shape imprinted into it, but thin enough so that it conforms to the curve of the camber and tips. We have had success with 18ga steel, but i'm considering stepping it up to 16ga or aluminum slightly thicker than 16ga.

Doug

-

doughboyshredder

- Posts: 1354

- Joined: Mon Sep 17, 2007 7:37 pm

so sick of this conversation.

O.K.

What are the benefits of not using a cat track? Really?

Doesn't matter for me, cause I am using 3 bladders. Doesn't matter for anyone using 2 bladders either.

Buuk, I appreciate that it's not a personal attack, but I have no way to respond. I have posted my opinions about what some of the reasoning is behind using a cat track. some people obviously disagree.

One of the other reasons to use a cat track is so that you are transferring the overall potential pressure from your air bags to the laminate. With a cat track, if you want to see 80psi on the laminate you may only need to inflate your air bladders to 60 psi. (depending on the surface area of your cat track, bladders, and laminate) Without the cat track you will only realize the potential pressure of the surface area of the laminate. So if you want 80psi at the laminate you will need to inflate the bladders to 80 psi.

bet I started another argument with that one.

It all has to do with potential pressure and realized pressure.

Knights, you're on the money.

O.K.

What are the benefits of not using a cat track? Really?

Doesn't matter for me, cause I am using 3 bladders. Doesn't matter for anyone using 2 bladders either.

Buuk, I appreciate that it's not a personal attack, but I have no way to respond. I have posted my opinions about what some of the reasoning is behind using a cat track. some people obviously disagree.

One of the other reasons to use a cat track is so that you are transferring the overall potential pressure from your air bags to the laminate. With a cat track, if you want to see 80psi on the laminate you may only need to inflate your air bladders to 60 psi. (depending on the surface area of your cat track, bladders, and laminate) Without the cat track you will only realize the potential pressure of the surface area of the laminate. So if you want 80psi at the laminate you will need to inflate the bladders to 80 psi.

bet I started another argument with that one.

It all has to do with potential pressure and realized pressure.

Knights, you're on the money.

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

the steel bars allow rigidity along the width of your work, yet allow for deformation longitudinally

the sheet of metal underneath the steel bars allows for pressure distribution between the contact points lengthwise that the steel bars cause

use an airbag without steel bars, and whatever you put over the ski/board will get bent over the layers, rendered useless for your next try

use airbag and steel bars without the steel/alu sheet underneath, you will get lines and pressure voids from only having steel bars above your work.

That's why we use both steel bar cattrack and sheets with some thickness.

the sheet of metal underneath the steel bars allows for pressure distribution between the contact points lengthwise that the steel bars cause

use an airbag without steel bars, and whatever you put over the ski/board will get bent over the layers, rendered useless for your next try

use airbag and steel bars without the steel/alu sheet underneath, you will get lines and pressure voids from only having steel bars above your work.

That's why we use both steel bar cattrack and sheets with some thickness.

Doug

- Dutchjibber

- Posts: 19

- Joined: Fri Mar 17, 2006 1:07 am

- Location: Delft, The Netherlands

*Off topic*

Skibuilding is at a small pause at the moment as I am writing this from Austria!

*off topic*

Good point about the lengthwise shifting by the cattrack. This is definately something we need to have a good look at.

How large is your bladder? I think this really defines which option is best.

Skibuilding is at a small pause at the moment as I am writing this from Austria!

*off topic*

Good point about the lengthwise shifting by the cattrack. This is definately something we need to have a good look at.

How large is your bladder? I think this really defines which option is best.

-

knightsofnii

- Posts: 1148

- Joined: Tue Jan 08, 2008 6:02 am

- Location: NJ USA

- Contact:

yes it totally does....

narrow bladder = use a cat track, as it will disperse the pressure across the width no matter how wide bars you use.

wide bladder = use a cat track, as it will keep your bladder from pinching over your sidewalls!!!

if you have a bladder that will conform perfectly to your ski shape, or snowboard shape, then go for that. haha good luck.

You CAN get one that pushes down only the width of the narrowest point, to compensate for loss across the sidewall just use a thick plate...i suppose this way you could avoid a cat track, but you may run into pressure issues near the curved tips.

I know there are people that dont use them.

I wish they would chime in with specifics about how they avoid such things as the airbag pinching over the edges of the top, or how they keep their top sheet of whatever from getting the outline of the ski wrinkled into it.

Because I know one or two of them are successful at it.

I also know there are others that are using just the bag over top and some thin protective sheet or something, and capping boards/skis, and you should look to for their input.

And someone else said you cannot make a cap board with cat track method that you can only do it with just the top airbag.

You can make a cap board if your top cassette is shaped as a top mold to cap the board, then using the cat track the same way you make a sanwich board. This is a high output production method and is more expensive because the top cassette imprint requires cnc machining of metal.

narrow bladder = use a cat track, as it will disperse the pressure across the width no matter how wide bars you use.

wide bladder = use a cat track, as it will keep your bladder from pinching over your sidewalls!!!

if you have a bladder that will conform perfectly to your ski shape, or snowboard shape, then go for that. haha good luck.

You CAN get one that pushes down only the width of the narrowest point, to compensate for loss across the sidewall just use a thick plate...i suppose this way you could avoid a cat track, but you may run into pressure issues near the curved tips.

I know there are people that dont use them.

I wish they would chime in with specifics about how they avoid such things as the airbag pinching over the edges of the top, or how they keep their top sheet of whatever from getting the outline of the ski wrinkled into it.

Because I know one or two of them are successful at it.

I also know there are others that are using just the bag over top and some thin protective sheet or something, and capping boards/skis, and you should look to for their input.

And someone else said you cannot make a cap board with cat track method that you can only do it with just the top airbag.

You can make a cap board if your top cassette is shaped as a top mold to cap the board, then using the cat track the same way you make a sanwich board. This is a high output production method and is more expensive because the top cassette imprint requires cnc machining of metal.

Doug