Medipore failure

Moderators: Head Monkey, kelvin, bigKam, skidesmond, chrismp

-

KindredSnow

- Posts: 13

- Joined: Wed Nov 30, 2011 10:41 am

- Location: Comox Valley, BC

- Contact:

Medipore failure

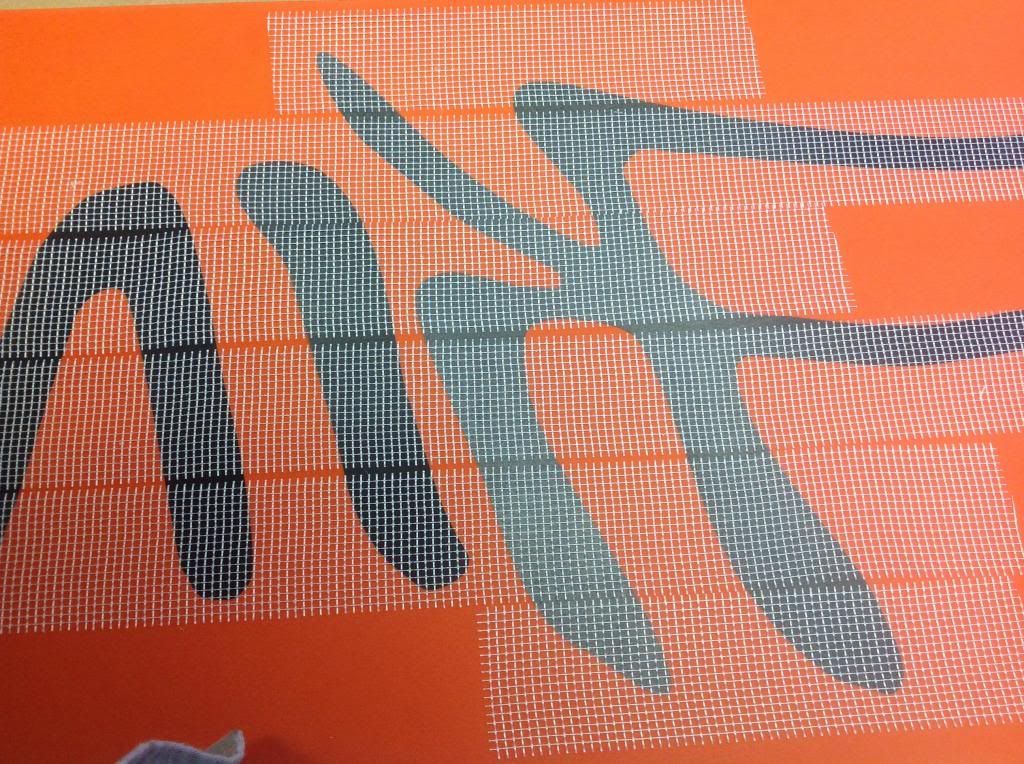

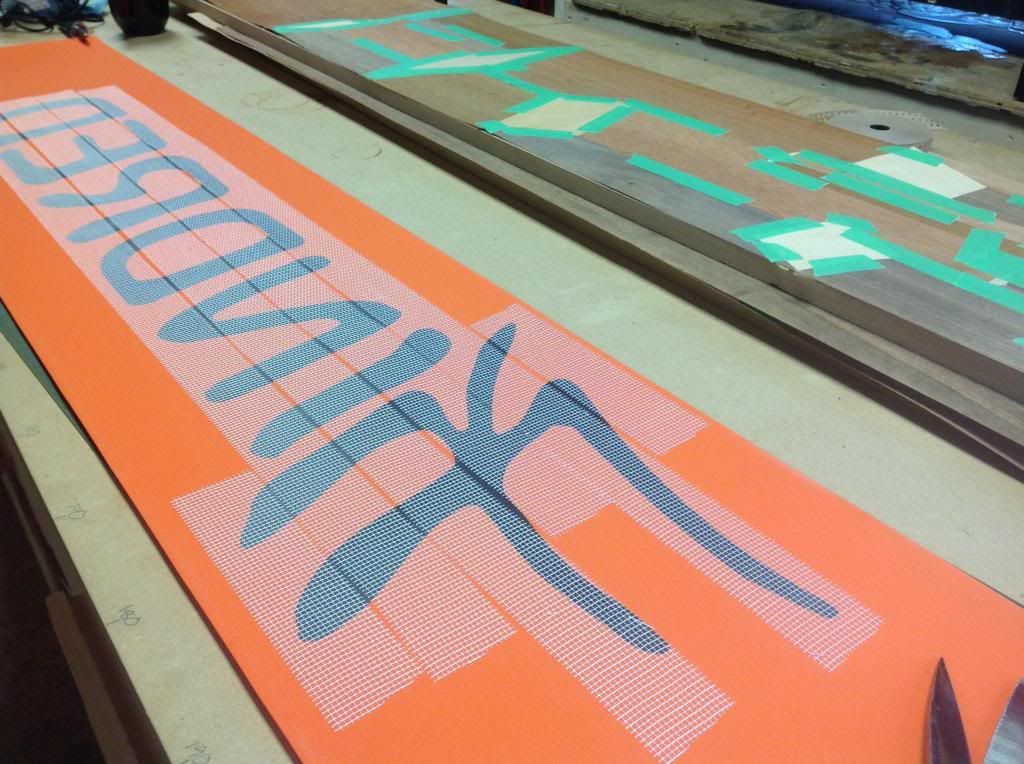

Just thought I'd share a frustrating moment today, maybe a warning. I've been using medipore tape to hold the die cuts in the base, leaving it inside the layup. No issues with the bond anywhere else other than where the tape was applied. The porous tape wets out well and goes totally opaque but there is very little hold.

I'm hoping this is an isolated incident as I've built a few boards/skis using this method, none of which have seen snow yet, though it seems these failures only occurred in areas where the tape covered the entire area of the inset piece.

I think using the tape on the running side might be a better choice...

Can't seem to figure out these photos?!

[img]http://s1360.photobucket.com/user/efair ... 051304.jpg [img]

[img]http://s1360.photobucket.com/user/efair ... b54766.jpg [img]

I'm hoping this is an isolated incident as I've built a few boards/skis using this method, none of which have seen snow yet, though it seems these failures only occurred in areas where the tape covered the entire area of the inset piece.

I think using the tape on the running side might be a better choice...

Can't seem to figure out these photos?!

[img]http://s1360.photobucket.com/user/efair ... 051304.jpg [img]

[img]http://s1360.photobucket.com/user/efair ... b54766.jpg [img]

-

KindredSnow

- Posts: 13

- Joined: Wed Nov 30, 2011 10:41 am

- Location: Comox Valley, BC

- Contact:

-

KindredSnow

- Posts: 13

- Joined: Wed Nov 30, 2011 10:41 am

- Location: Comox Valley, BC

- Contact:

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

Why are you using so much tape? Bummer that the medipore didn't work, but I bet that other stuff will work fine, but I think you're over-doing it. You just need enough to hold it in place during layup and into the mold. Once its under pressure, things can't move.

That's some fantastic fit by the way, are you drag-knifing those yourself? Great work.

Tape on the running side will give you a horribly dimpled base, don't do that, unless you do a full-width, full length, piece of something (like contact paper or vinyl application tape... something that can take the heat)

That's some fantastic fit by the way, are you drag-knifing those yourself? Great work.

Tape on the running side will give you a horribly dimpled base, don't do that, unless you do a full-width, full length, piece of something (like contact paper or vinyl application tape... something that can take the heat)

-

KindredSnow

- Posts: 13

- Joined: Wed Nov 30, 2011 10:41 am

- Location: Comox Valley, BC

- Contact:

I think your probably right, it does seem like overkill. I cut the base to shape and the router doesn't like having to cut through the fibreglass tape either.

I have also tried packing tape on the running side to hold them in place, but resin "pooled" in the centre, leaving a dimple. No issue with the thickness of the tape itself though.

Donek tool to cut the bases, very happy with it.

What do you use to hold your die cuts together twizz?

I have also tried packing tape on the running side to hold them in place, but resin "pooled" in the centre, leaving a dimple. No issue with the thickness of the tape itself though.

Donek tool to cut the bases, very happy with it.

What do you use to hold your die cuts together twizz?

Over use of tape with definitely cause delams. I've been told this by the Burton R&d guys. Use only enough to keep the die cut in place but not so much as to interfere

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

-

twizzstyle

- Posts: 2204

- Joined: Tue Mar 07, 2006 8:25 pm

- Location: Kenmore, Wa USA

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

-

KindredSnow

- Posts: 13

- Joined: Wed Nov 30, 2011 10:41 am

- Location: Comox Valley, BC

- Contact:

Check out around 2:00, they are using a fibreglass tape as well.

I just wasn't able to get good results with a packing tape. The outside of the tape would stay adhered, while the area directly over the joint would collect resin, leaving a crevasse too deep to take out with the grinder.

Edit:

2:26 it shows the bottom of the bases also covered in packing tape...

I think as long as you don't tape the entire joint it should be fine. Just leave exposed bondable surface on both pieces

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

I've used the fibreglass tape to hold tip spacers on too. Works well and I guess theoretically strengthens the joint. The reason I changed to medipore for holding tip spacers on was that my fibreglass tape just wasn't very sticky and I couldn't get it to hold the tipspacer on when transferring from layup table to my cassette. So really it wasn't doing its job.

You could try using sticky backed plastic (like they cover the sublimated topsheets with) to cover the whole of your base material and then place your inlay pieces down in their holes.

I have only done one very simple die cut where I butted 2 colours of base material together to use scraps. I laid a piece of sticky backed plastic across the join from one side of ski to the other (prob 2 inches wide) on the base side. Join was good. Small depression created ground out no worries.

You could try using sticky backed plastic (like they cover the sublimated topsheets with) to cover the whole of your base material and then place your inlay pieces down in their holes.

I have only done one very simple die cut where I butted 2 colours of base material together to use scraps. I laid a piece of sticky backed plastic across the join from one side of ski to the other (prob 2 inches wide) on the base side. Join was good. Small depression created ground out no worries.

Don't wait up, I'm off to kill Summer....

I find even with medipore that the tipspacer joint can still slip if you are not careful. I use an interlock tip spacer shape. I place pieces wood-plastic joint on each side both top and bottom. I do make sure to kind of flood this area with resin to make sure this is no void there. Keeping the joint between the wood and the spacer tight also helps prevent movement. I also place a couple pieces along the lenght of the joint on the base side and one at the very tip. But as I said above, don't cover the whole joint. You want bondable material there and for resin to infiltrate the seam.

Fighting gravity on a daily basis

www.Whiteroomcustomskis.com

www.Whiteroomcustomskis.com

- MontuckyMadman

- Posts: 2395

- Joined: Fri Jun 20, 2008 9:41 pm

Looks pretty dry in your image for die cut. Try some bonding rubber in there. Like I said all use packing tape i only had a bubble once that was tough to grind. More resin In the layup.

Could the delam be from Over heating from grinding or waxing? The die cut section is a bit sensitive.

Could the delam be from Over heating from grinding or waxing? The die cut section is a bit sensitive.

sammer wrote: I'm still a tang on top guy.

I'm following this because we have been using it with good luck for 'tacking' tip/tail spacers on prior to layup. We are using a small piece to hold it in place within the extents of the ski perimeter. Are others doing this to? I'm sure I read at some point about this but I can't find it at the moment.

I use a piece of medipore tape top and bottom of core. Maybe 3 inches long and lay it along the joint (not extending outside the layup). Have probably thought might be better to use two pieces longitudinally rather than the one laterally across the ski.

Lately been a bit frustrated with it as I spend a lot of time making sure it wets out well and once I do this it seems to lose all its stickiness and the tip spacer can move again anyway.

I haven't had any problems with delam (so far?).

I you use it with a clear topsheet you can see it a bit too even if it is wet out well.

Lately been a bit frustrated with it as I spend a lot of time making sure it wets out well and once I do this it seems to lose all its stickiness and the tip spacer can move again anyway.

I haven't had any problems with delam (so far?).

I you use it with a clear topsheet you can see it a bit too even if it is wet out well.

Don't wait up, I'm off to kill Summer....