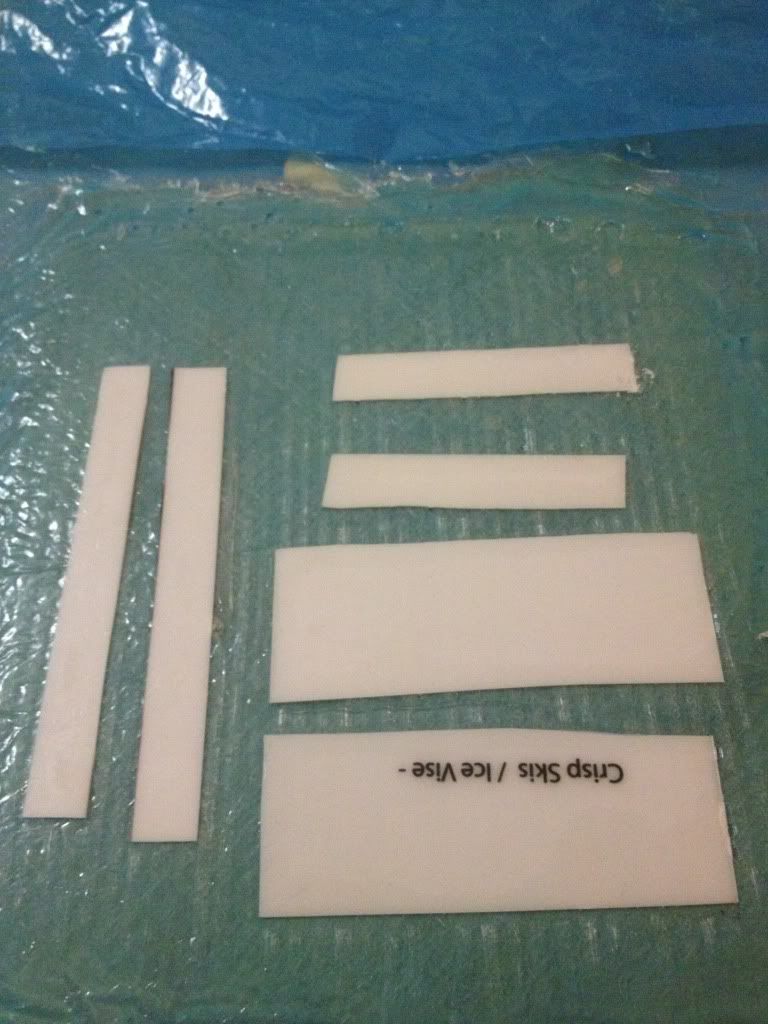

I had some topsheets done my Miller studio on white nylon abraded and treated for bonding.

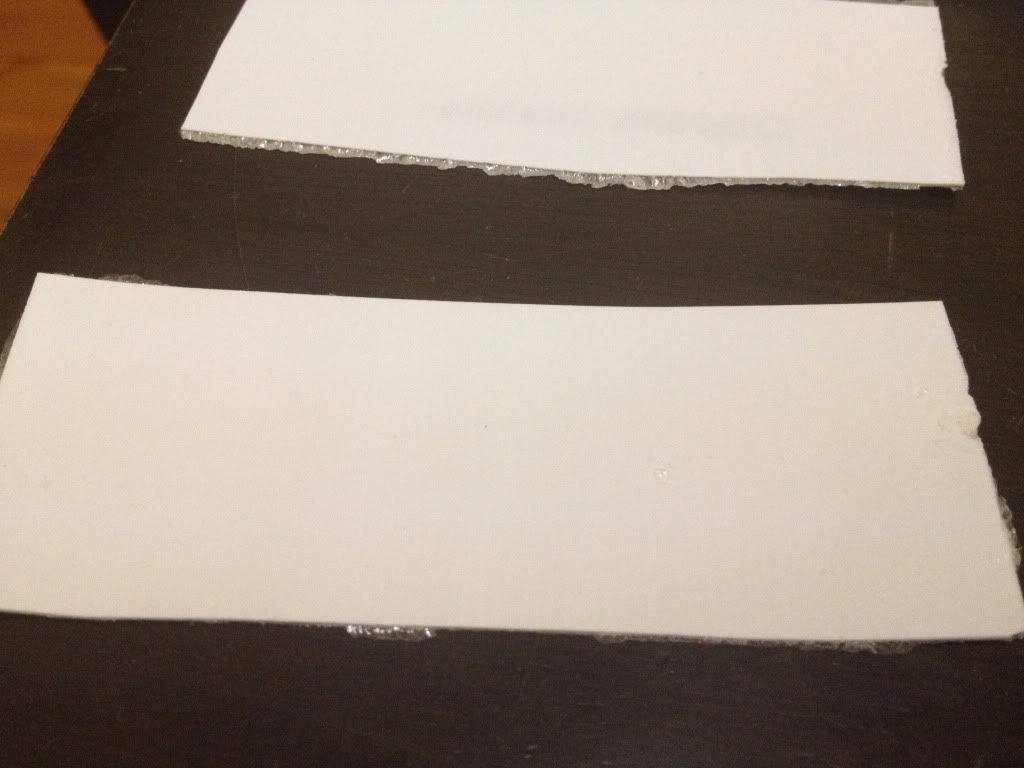

In layup last night things seemed to go pretty well and the skis appear to have cured and held shape, however this morning I noticed that the edges of nylon topsheet didn't seem well bonded and the whole topsheet just peeled off like a peel ply. Not even a few spots of adhesion.

Parameters:

Room temp cure epoxy - under pressure 50psi for 12 hours

Heater running and ambient temp in room 18C

Propane torch flame treatment prior to layup (have never done this before)

Mix ratios good, mixing good. Upper glass layer perhaps slightly low epoxy, but not greatly.

Nylon bond surface appeared clean

Problems?:

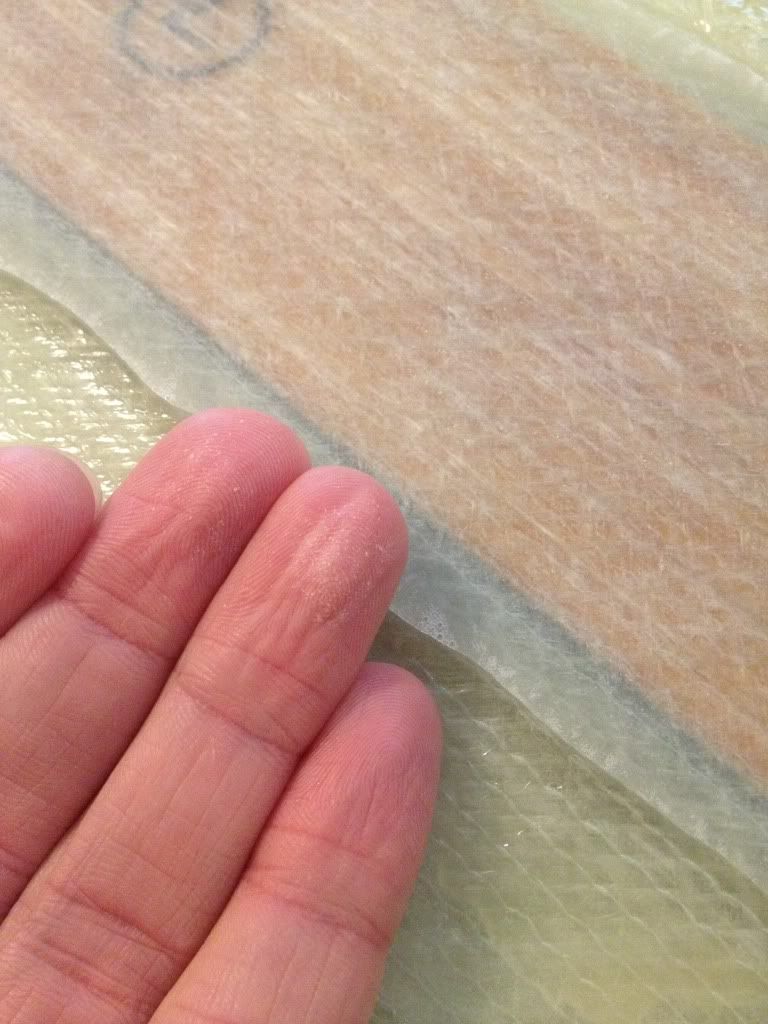

Major one is that after peeling the nylon topsheet there are large white areas where the epoxy surface has gone powdery (can pick it up on your finger). This powder can be seen on the under side of the nylon also.

Top glass layer

Powdery residue

Theories:

Number one is that lower ambient temp and probably high humidity (winter - temp dropping late in day rapidly) led to amine blush forming between the glass layer and the nylon = no bonding. Even though room temp was 18C the heat sink of aluminium cat track etc maybe meant top layer was much colder (?) and this slowed curing. Also enclosed room to hold heat prob held CO2 also and this helps create amine blush.

Number two. Nylon just poorly adherent. Either factory treatment worn off during shipment and handling, or my effort at flame treatment actually ruined the flame treatment. Residue from flame acted as a release agent?

Number three - my epoxy system is not compatible with nylon even when abraded and flamed.

Number 4 - deficient epoxy volume. Upper glass layer was wet but could have been wetter probably. I just laid the topsheet plastic on this glass layer rather than wetting the underside of the topsheet (I know some people do wet the underside of the nylon). I don't think this would have led to complete failure to bond however.

Any help appreciated as I have a few more nylon topsheets on hand that I am too nervous to use now.