Page 1 of 2

to rebate/rabbit

Posted: Tue Dec 25, 2012 2:19 pm

by mikic1

I got a good idea of what it is, and I find the term on the forum a lot, and not that I am working on a pair with tip spacers, can somebody explain/confirm the rabbit/rebate term, what is it (perhaps my English vocab. is not on the level)

Cheers

M

Posted: Tue Dec 25, 2012 3:24 pm

by twizzstyle

The rabbit/rabbet/rebate is a shoulder cut into the bottom of the core/sidewalls along the side to account for the thickness of the edge teeth that sit on top of the base sheet. The idea is that when all layers are pressed together, they all sit flat on each other without any voids.

Without the rabbit, the core/sidewalls would form a bridge across the edges, and there is a void under the core. The most common effect of this is base concavity (the core is pressed down between the edges, and when pulled from the press it relaxes and pushes the sides of the base down).

I used to do a rabbit, but now I do a 3" wide layer of uni carbon fiber that basically fills that space.

I don't do a rabbit on my tip/tail spacers cause I don't care if those areas are perfectly flat.

Posted: Tue Dec 25, 2012 4:02 pm

by Jekul

My symptoms were different than having a concave base. I would have small voids/ concave areas in the base near the edges (never in the middle). Since I started to recess the core for the edges this problem has gone away.

Posted: Tue Dec 25, 2012 4:21 pm

by mikic1

great explanation twizz, thanks a lot!

Posted: Wed Dec 26, 2012 12:05 am

by Dr. Delam

I would also get indentation marks on the base where the edge flanges are if I didn't do a rabbet on the core/sidewall. I could grind it out but the less grinding I do after pressing, the better.

Posted: Sat Nov 26, 2016 8:53 am

by skimann20

I'm digging this one back up again... because I like to search. ;-)

Okay so I just got done crying... I ground through my first base.

Here is my lay up. I use unicarbon in my layup and always put a rabbet on the core. right at about .7/.9mm

my skis always come out base high (middle) of the ski. hence the reason I ground through this ski. i guess I was base high more than the base depth...

So the question is. should I reduce the rabbet depth, or eliminate it all together?

I'm going back down the basement to figure out a good place to wall mount these...

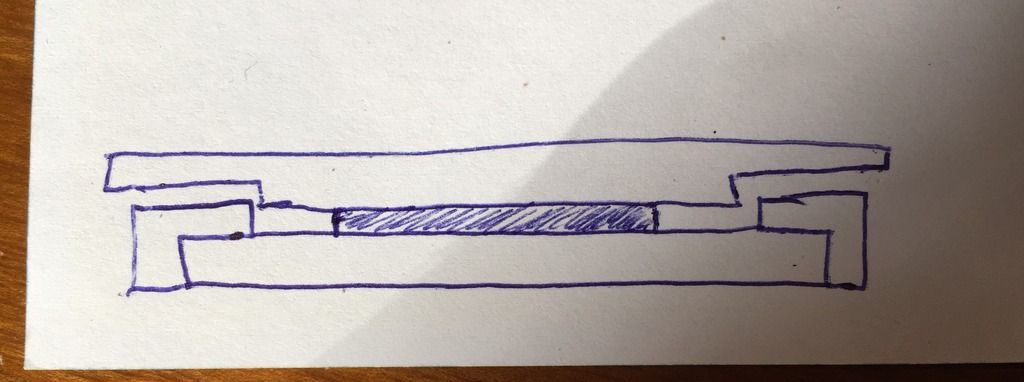

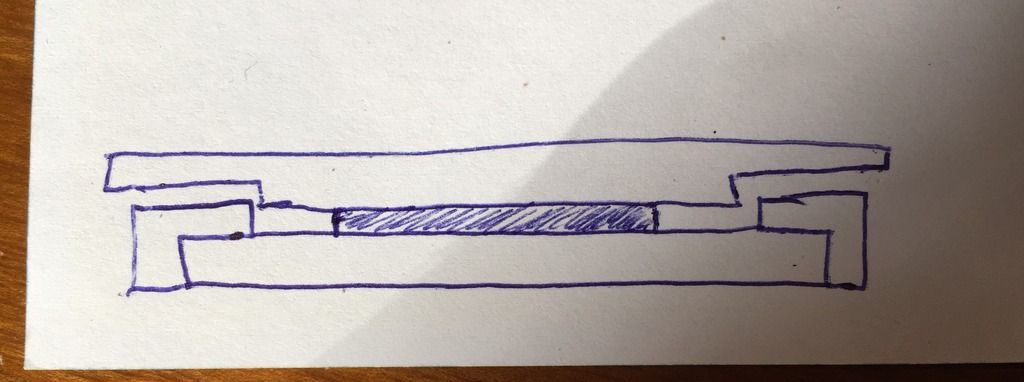

image for reference, colored in part is the CF (not to scale), and you can figure the rest out:

Posted: Sat Nov 26, 2016 11:42 am

by Hannes

Why don´t you use lighter Carbon but for the whole width? Above the edges as well?

Posted: Sat Nov 26, 2016 12:19 pm

by MontuckyMadman

Do u use a cattrack?

Posted: Sat Nov 26, 2016 1:19 pm

by skimann20

I'd rater not to full width but I would consider it. I'd actually like to go to stringers but I'm not sure what toe to go with.

MontuckyMadman wrote:Do u use a cattrack?

Yes full length/width steel cat track. I see it the base high on both skis. mainly in the tips and tails. So my thought is the CF in the middle of the ski is closer to the edge. so you don't get as much of a gap, unlike the tip and tails that have more space between CF and edges allowing the for the base to "turn up" because its not under as much pressure as the middle of the ski.

Posted: Sat Nov 26, 2016 3:22 pm

by MontuckyMadman

Have you put a real true bar on the platen of the grinder? Could be domed.

Posted: Sat Nov 26, 2016 4:25 pm

by falls

With the CF in that space I don't think you need to rabbet nearly as deep as you are. You are probably getting strong pressure in between the edge teeth where the core is pushing down and weak pressure at the edges because the depth of your rebate plus the thickness of the CF is almost twice the depth of the edge teeth.

Read above where Twizz said he stopped rebating after starting to use a 3 inch piece of CF uni between the edge teeth. This is prob only 0.2-0.3mm thickness but you need to subtract that from your rebate at least. Go for 0.5mm depth max I would say.

Also check if your mold is flat side to side.

Posted: Sun Nov 27, 2016 4:50 pm

by skimann20

Hey Gang as always much appreciated.

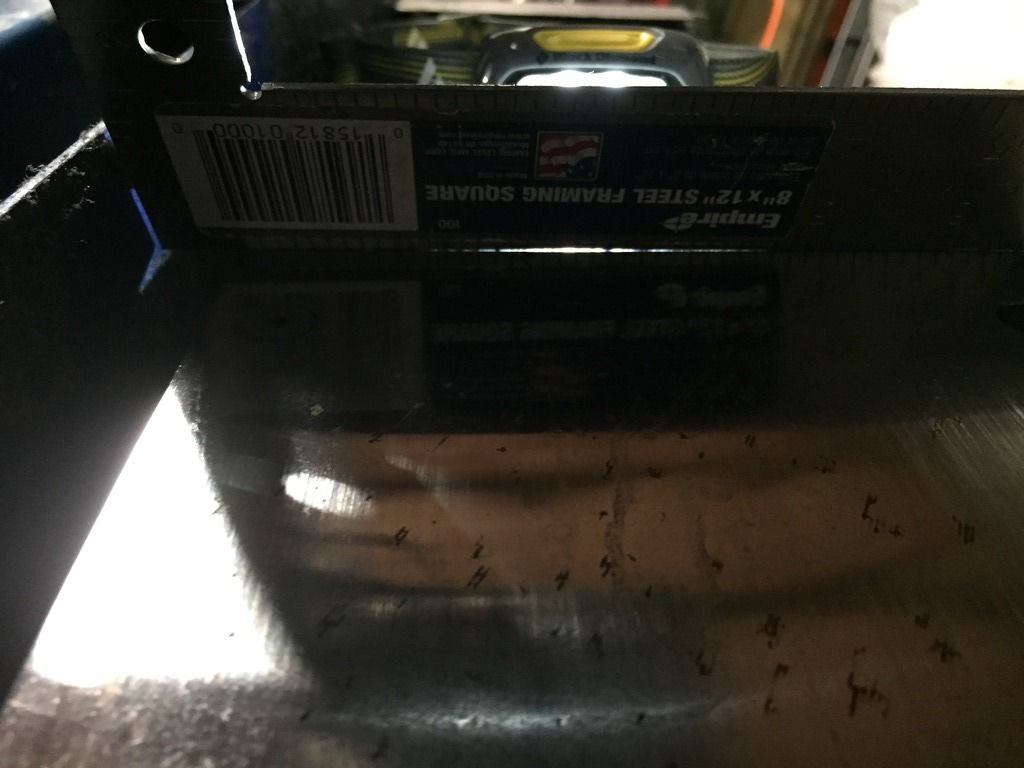

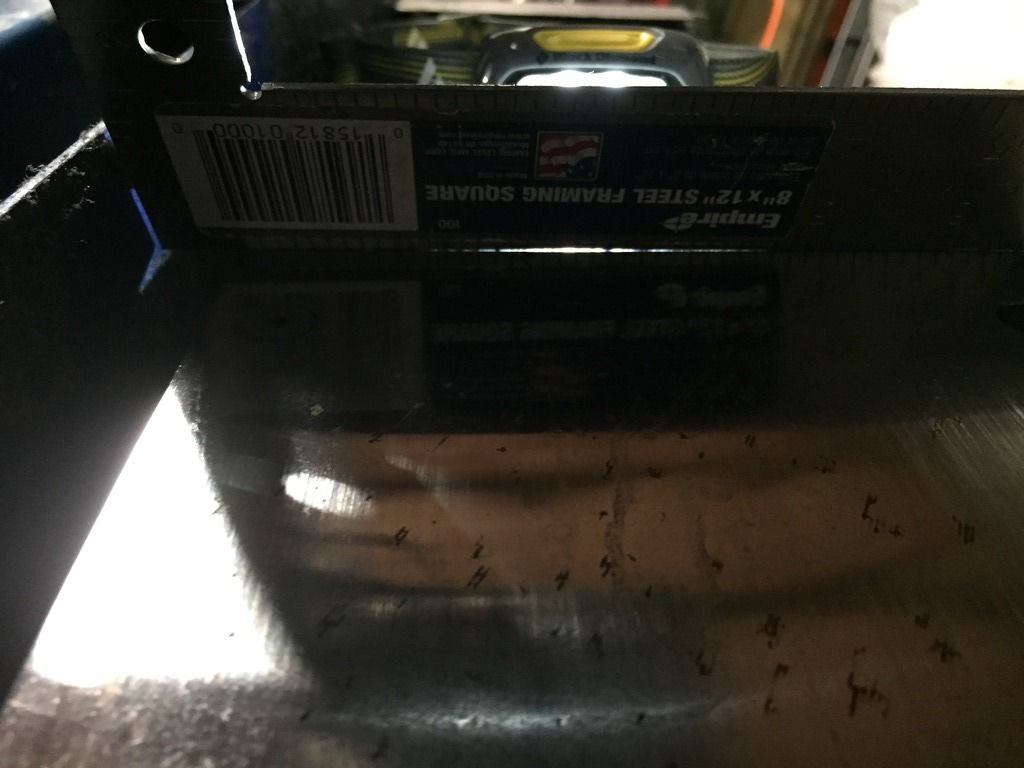

MM: checked it out. The one that I have on right now looks like this:

just a little concave. so opposite of what i'm having issues with.

my spare one looks like this... why would anyone want to use this!!! maybe it flattens out once it bolted down...

So I made some test "skis" and did some pressing on the press where I'm having issues. both pieces were side by side in the tip section.

here are some photos for your enjoyment:

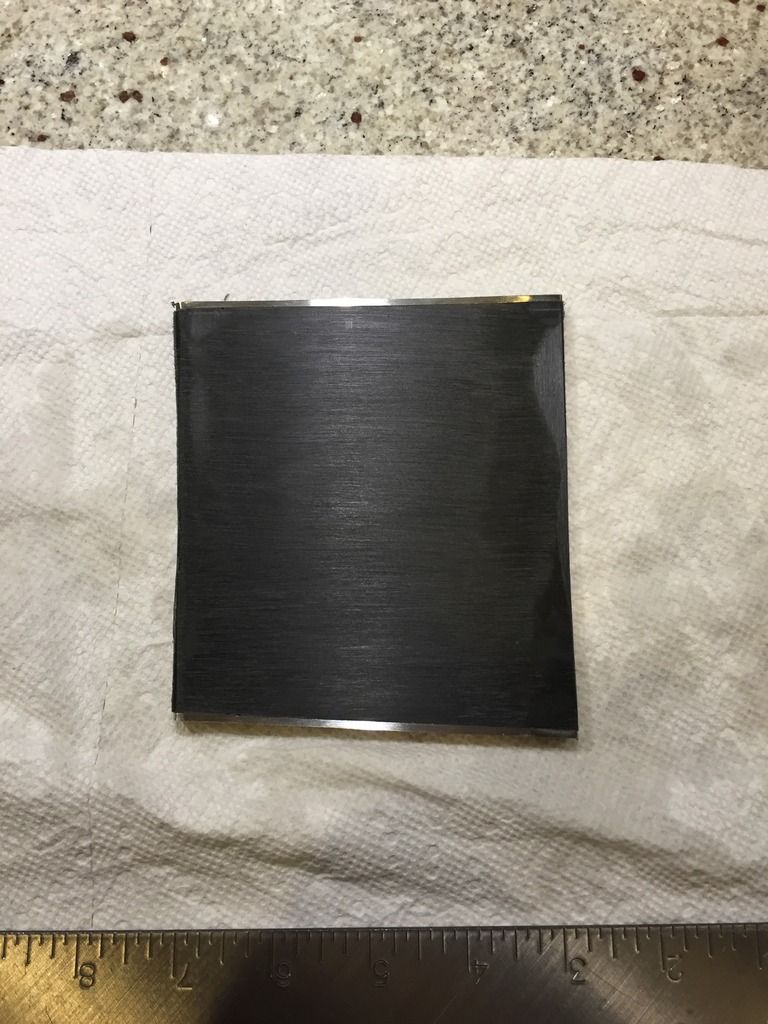

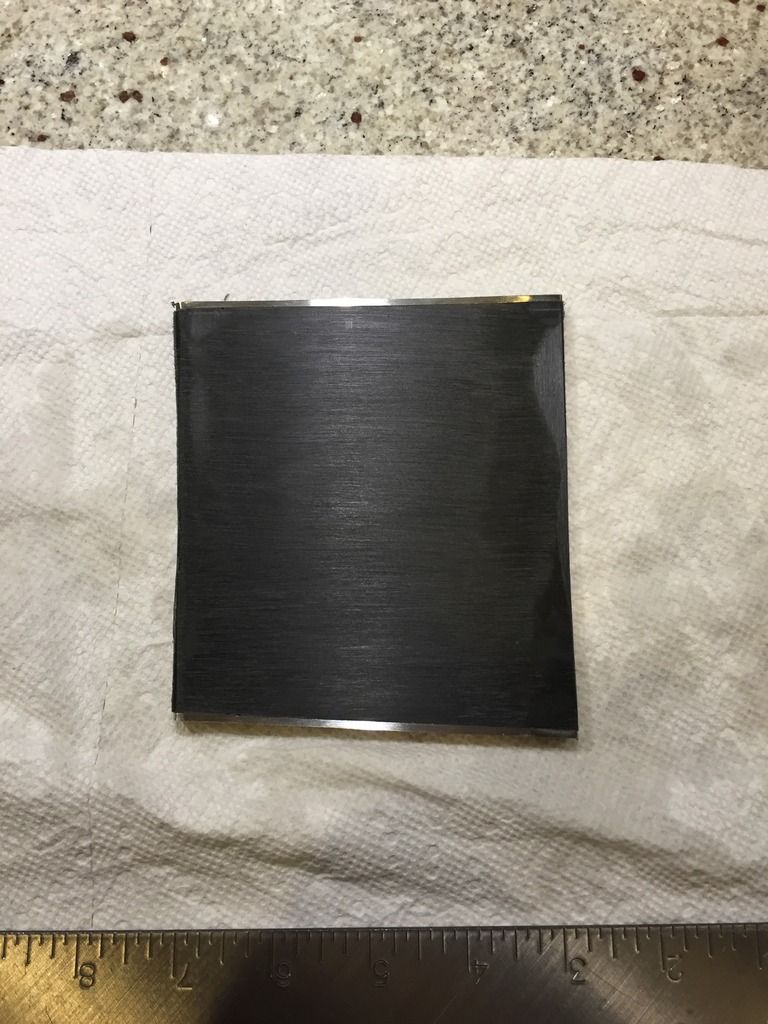

this core has no rabbet, i did three passes with a 120grit.

just as Twizz explained:

you can actually see how the base dives down after the edge teeth in this photo. want to take a guess what the height difference is from the edge to the middle of the ski? 0.7mm ;-) :

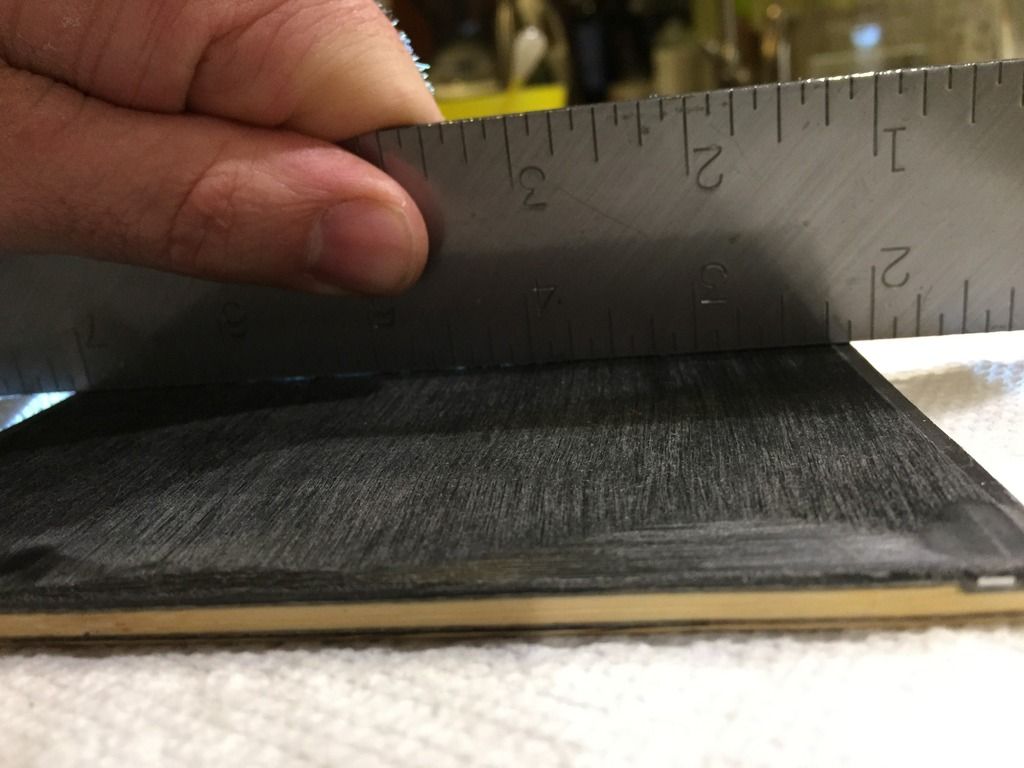

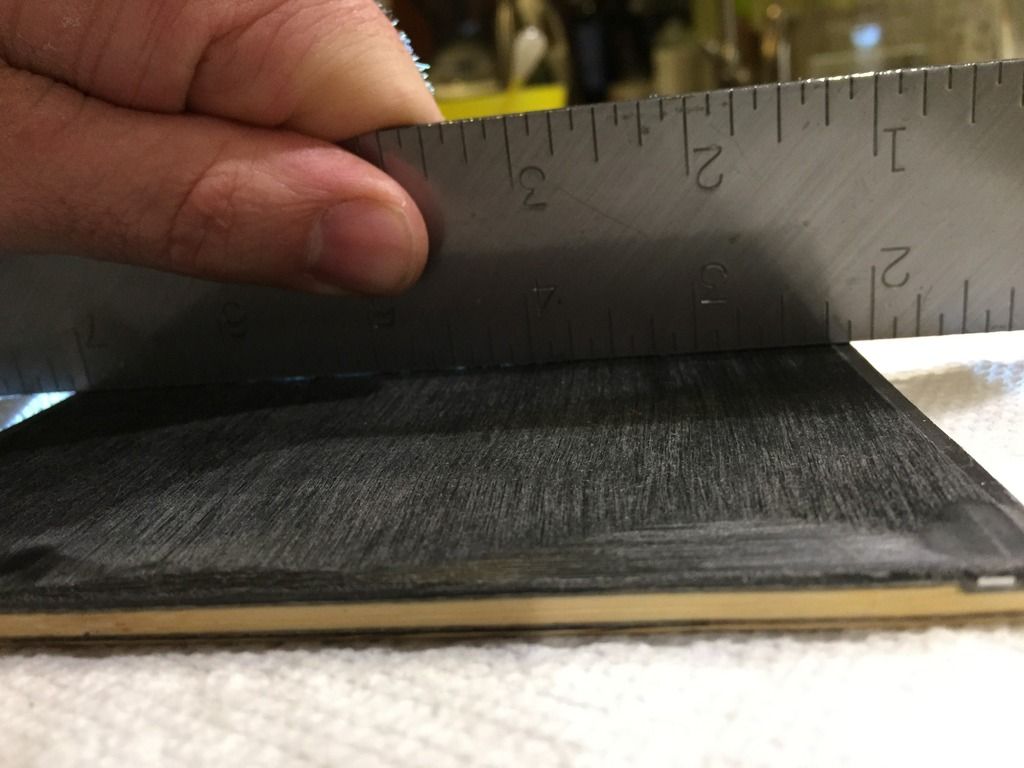

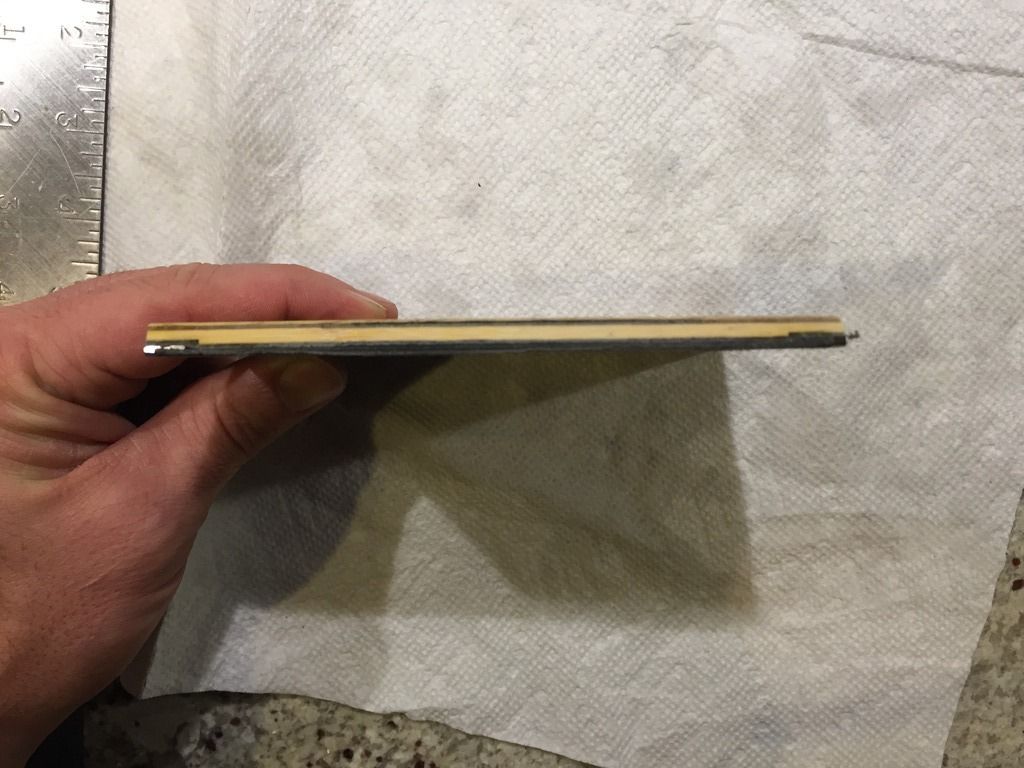

This test piece has a rabbet, four passes on the 120 belt:

dang flat after.

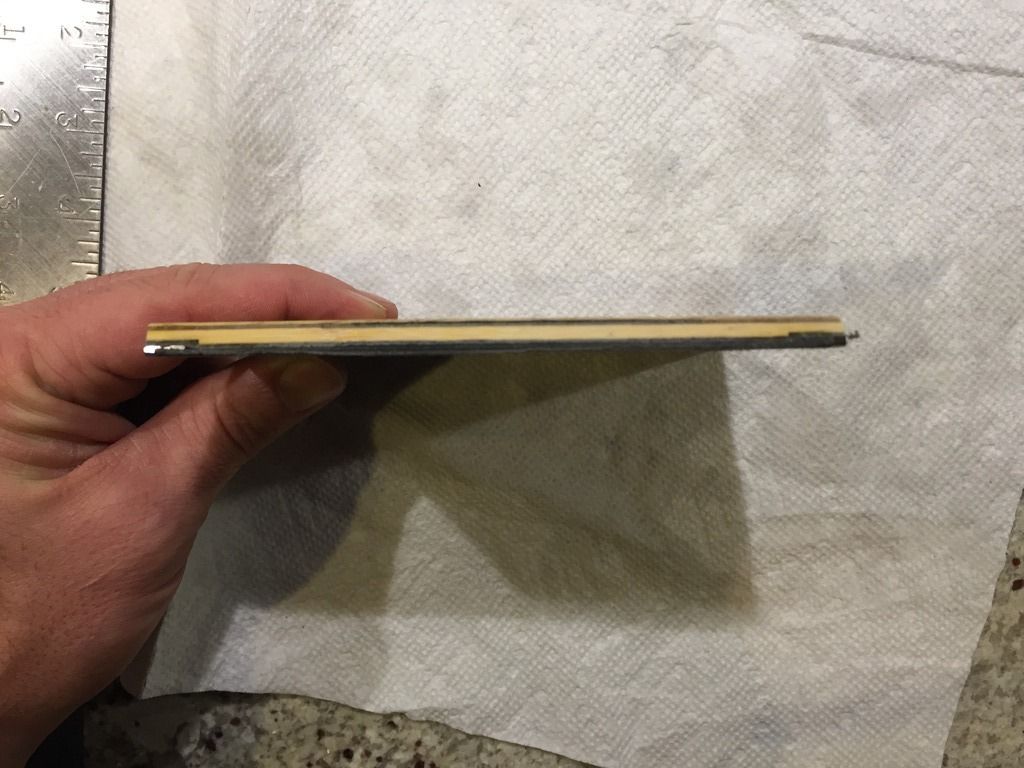

closeup of rabbet:

really the only thing that I didn't do with this test is make the test pieces in my ski cassette. I put the test pieces in parchment paper and placed it between my two heater cassettes. I'm wondering if the 6 sheets of aluminum I have in there is effecting the pressing. (AL-heat-AL AL-ski-AL AL-heat-AL) I would have expected the rabbeted test piece to be base high like the other skis i've made, so now i have a test piece that is awesome but not representative of what I've been getting. I'd cry in joy if my ski came out this flat.

other things I'm considering:

Do one more test layup with a rabbet at ~.4mm and one at ~.7mm and put them in ski cassette and see how they come out.

Maybe the pressure gauge on my compressor is wrong and I'm not pressing at 60psi.

Posted: Sun Nov 27, 2016 6:23 pm

by MontuckyMadman

Perhaps your tc position is off? I would do the tests again with all your al in there. Are you cooling slightly before pulling? We pull at 150f-160f.

We had flatness issues when pulling at 180-170f.

Posted: Sun Nov 27, 2016 6:49 pm

by twizzstyle

Great looking cross sections!

Do those test pieces have the CF? Hard to see it if it's there. Do you have a cat track? How hot are you curing, and is your layup otherwise symmetric top and bottom? You can get camber differences with temperature changes if your layup isn't the same top and bottom, base concavity/convexity is less likely (especially with no lateral fibers) but could be a possibility I suppose.

Posted: Sun Nov 27, 2016 7:04 pm

by skimann20

MontuckyMadman wrote:Perhaps your tc position is off? I would do the tests again with all your al in there. Are you cooling slightly before pulling? We pull at 150f-160f.

We had flatness issues when pulling at 180-170f.

TC?

two new test pieces already made and ready to go. rabbeted at .40mm and .80mm (the barfs are going through the family and it looks like I just won the golden ticket. so they are going to have to wait till tomorrow) I pull at 120-140. once you hit 180, how long do you let yours cook? do you go past the 18min? i let mine go well past the allotted 18min.

Twizz:

yes Cf both top and bottom at 2" 9oz. triaxial FB with 45 on the outside and straight running closest to core.

Steel Cat track.

I do seem to get base high (meaning have to grind more away in the inside edge) on the inside. outside edgess are always last to see belt. This is me being supper nitpicky. the ski i ground through the base was this way. more toward the inside edge.