Size: 180cm (135-107-126) 6mm camber

Core: Maple w/(2)poplar strips 2.25-12-2 (tip 60mm rise in 400mm), (tail 45mm rise in 250mm)

Sidewalls/Tipspacers: UHMW

Base: Isospeed 7200

Fiber: 22oz triax/3" strip 5oz uni CF above and below core

VDS on top of edges and full area of tip and tail

Topsheet: PBT sub'd by Coda/ graphic done in photoshop and illustrator

Epoxy: Super Sap 100/1000

Press: 60psi@180f for 60min pulled out hot.

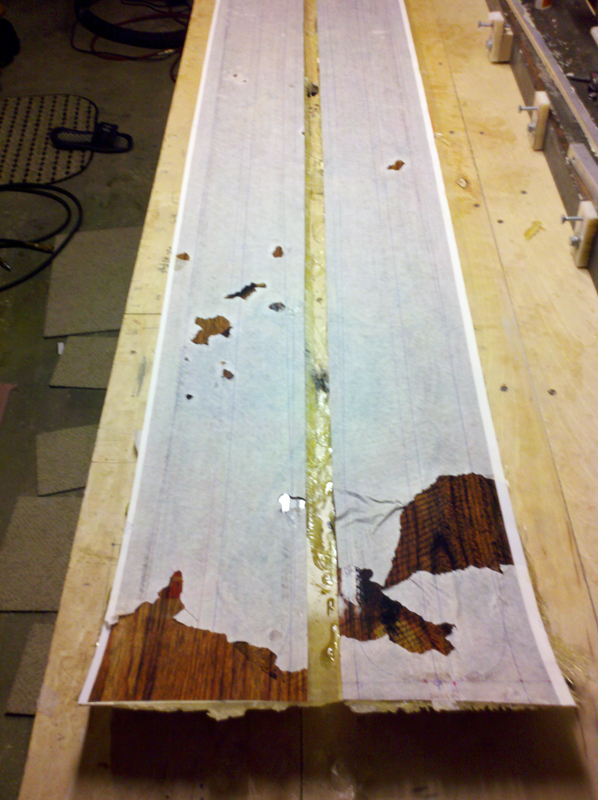

Fresh out, you can see the graphic alignment drawn on the protective paper so no element got cut off. Some of the paper stuck to the top cassette,topsheet unhurt.

Glueing the sidewall in my DIY glue press (I also use this to glue the core block and join the core slices.)

Cores glued, and inserts drilled. These were profiled on a crib in a planer.

finished skis (the marks are just glare)

3/4 edge wrap and no sign of tip fall, although the curve up is gradual which helped as I did not prebend.

Tip and tail rise came out nice. The sidewalls are beveled to 18d.