Yea reno's are just about done!! i have a living room i can sit and watch tv in, and a dining room i can eat in. My computer is up and running so now its time to finish my story.

While I was waiting for drywall mud to dry I got a chance to lay up my first ski. I used double sided carpet tape to hold my base to my template then cut out 1 base.

while it was still taped down i glued on my edges

the only problem here was that some super glue migrated under the base and glued it firmly to my template i got it off with a razor knife. but it left some MDF permanently attached to the bottom of my base.

next i gently bent the base to fit the mold used a piece of 2" abs pipe

then it was time for a dry fit to make sure i knew what i was doing.

had to glue in some pieces of paneling to aid in core alignment

I hot glued some aluminum window screen for some binding retention, you can see the bumps of glue in the finished ski

I cut both layers of triax to go around the aligners

then it was time for the layup. I was way too busy and gooey to get any pics.

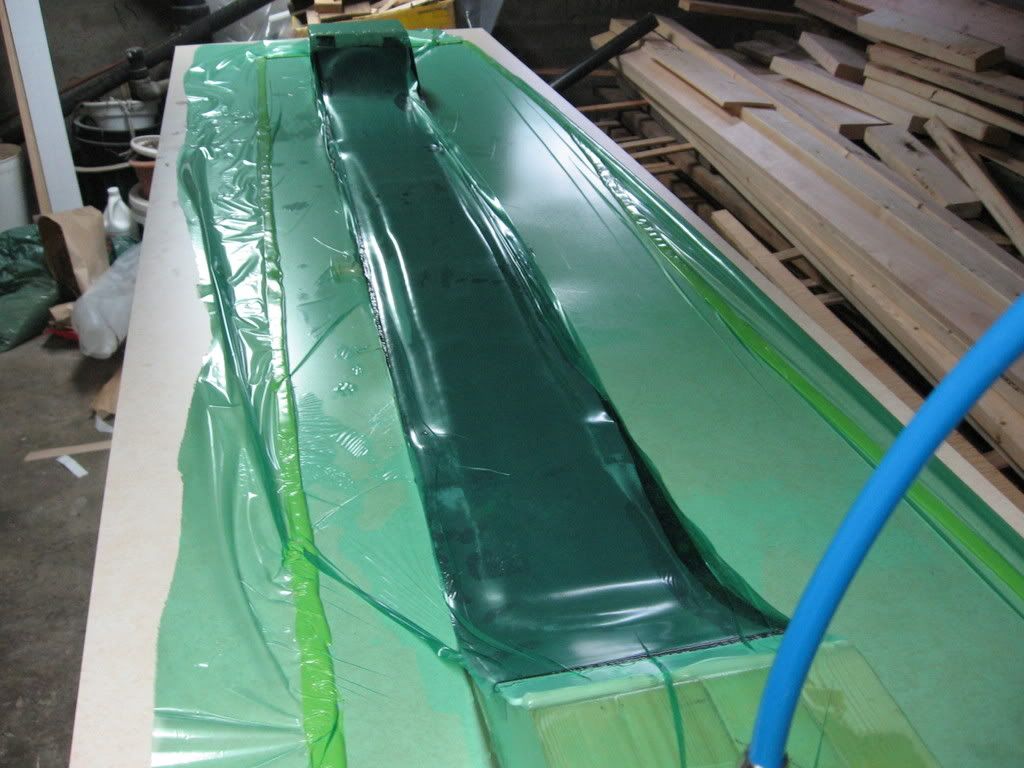

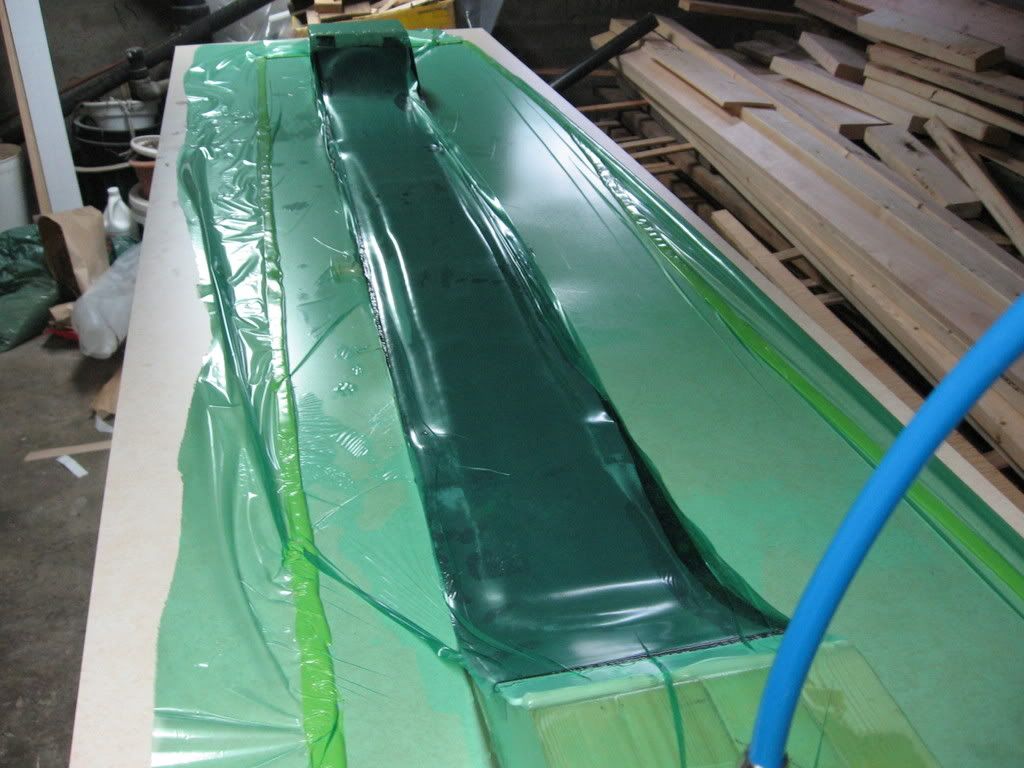

But once it was in the bag and sealed up the camera came back out

I left it sucking all night with my cheap electric blanket on it set on medium/high. when i woke up in the morning it was 127f. A little warmer than i would have liked. I'm using west system with slow hardener.

when i got it out of the mold and took it out into the sunshine heres the result.

I did get quite a bit of epoxy under my bases in the tip and tail and they are a bit concave near the edges. You can also see the MDF super glued to the base.

Cutting away the flash was a piece of cake, Bought some cheap "Task" fiberglass blades for my jig saw. worked quite well

Heres the happy girl with the first ski she only needs one until the cast comes off

The second ski i built a couple of weeks later. the process was exactly the same only i spent a bit more time rolling the air out from under the top sheet.

the only thing I'm not sure about is the crazy camber i got from my mold design. The vacuum sucked the mold down to the table so the finished ski has about 10mm of camber right under foot and is flat at the tips and tails.

i guess we'll see how it works in a few months.

and here's chelsea again, poor girl spent the entire summer break in the cast (trampoline accident) got it off 3 days before school started

the finished product is 127cm 112,73,95. All in all I'm pretty darn happy with my first attempt.

started on my own skis last week using pretty much the same process so my next post here will be shorter.

sam

You don't even have a legit signature, nothing to reveal who you are and what you do...

Best of luck to you. (uneva)